Preparation method of biodegradable copolyester hot melt adhesive

A biodegradable, copolyester technology, used in adhesives and other directions, can solve problems such as the impact of degradable properties, and achieve good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A preparation method of biodegradable copolyester hot melt, the steps are as follows:

[0017] (1) Dibasic acid consisting of 166g of terephthalic acid, 66.4g of isophthalic acid, 34.5g of dodecanedioic acid and 10.1g of sebacic acid, 177.3g of butanediol and 44.84g of 1 , a diol composed of 3-propanediol, and a catalyst composed of 0.0107g of tetrabutyl titanate and 0.0107g of antimony acetate are added to a 1L esterification reactor at a reaction temperature of 160°C to 205°C. When the amount of distilled water in the reaction kettle is 95% or more of the theoretical water output, the esterification reaction ends;

[0018] (2) Add 1.3345g of antioxidant 1010 to the product of step (1), carry out the polycondensation reaction at 230°C-240°C and 100Pa-150Pa for 2.0h, and then release the vacuum with nitrogen gas. Serve hot.

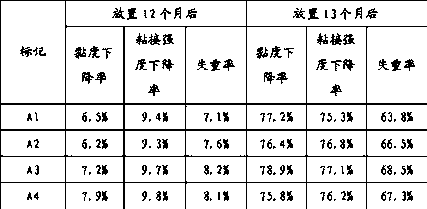

[0019] The product prepared by Example 1 is labeled A1.

Embodiment 2

[0021] A preparation method of biodegradable copolyester hot melt, the steps are as follows:

[0022] (1) Dibasic acid and dibasic alcohol as in Example 1, and a catalyst composed of 0.019g tetrabutyl titanate and 0.0237g antimony acetate, are added to a 1L esterification reactor, and the reaction temperature 160 ℃ ~ 205 ℃, when the amount of distilled water in the esterification reactor is 95% or more of the theoretical water output, the esterification reaction is over;

[0023] (2) Add 1.6014g of antioxidant 1010 to the product of step (1), carry out the polycondensation reaction at 230°C-240°C and 100Pa-150Pa for 2.0h, and then release the vacuum with nitrogen gas. Serve hot.

[0024] The product prepared by Example 2 is labeled A2.

Embodiment 3

[0026] A preparation method of biodegradable copolyester hot melt, the steps are as follows:

[0027] (1) Dibasic acid and dibasic alcohol as in Example 1, and a catalyst composed of 0.0295g tetrabutyl titanate and 0.0185g antimony acetate, are added to a 1L esterification reactor, and the reaction temperature 160 ℃ ~ 205 ℃, when the amount of distilled water in the esterification reactor is 95% or more of the theoretical water output, the esterification reaction is over;

[0028] (2) Add 1.8683g of antioxidant 1010 to the product of step (1), carry out the polycondensation reaction at 230°C-240°C and 100Pa-150Pa for 2.0h, and then release the vacuum with nitrogen gas. Serve hot.

[0029] The product prepared by Example 3 is labeled A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com