Water-based lubricating agent for titanium alloy hot extrusion forming

A water-based lubricant, hot extrusion technology, applied in lubricating compositions, petroleum industry, devices for coating liquid on the surface, etc., can solve problems such as inapplicable hole expansion extrusion process, increased workload, stuffy car, etc. , to achieve the effect of improving cleaning performance and economic performance, increasing service temperature and improving lubricating effect

Active Publication Date: 2018-02-02

TSINGHUA UNIV

View PDF7 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method currently has the following problems: First, the copper skin in the inner hole is prone to breakage and needle sticking during the extrusion process, resulting in discontinuous lubrication, and it is not suitable for the hole expansion extrusion process

Second, after processing, it is necessary to remove the copper skin on the surface of the workpiece by pickling, which increases the workload and brings environmental pollution

Third, some titanium alloys react with copper to form copper-titanium alloys during processing, which greatly affects the surface quality

The problems of glass powder lubrication include: first, the composition selection and ratio of glass powder need to be adjusted according to the processing temperature, each type has a narrow applicable temperature, and the preparation process is complicated

Second, the glass powder is coated after the workpiece is heated, which takes a long time, causing the temperature drop of the workpiece to be too large

Third, uneven lubrication can easily cause problems such as stuffy cars

[0006] Therefore, the existing lubrication methods in the hot extrusion process of titanium alloy still need to be improved.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

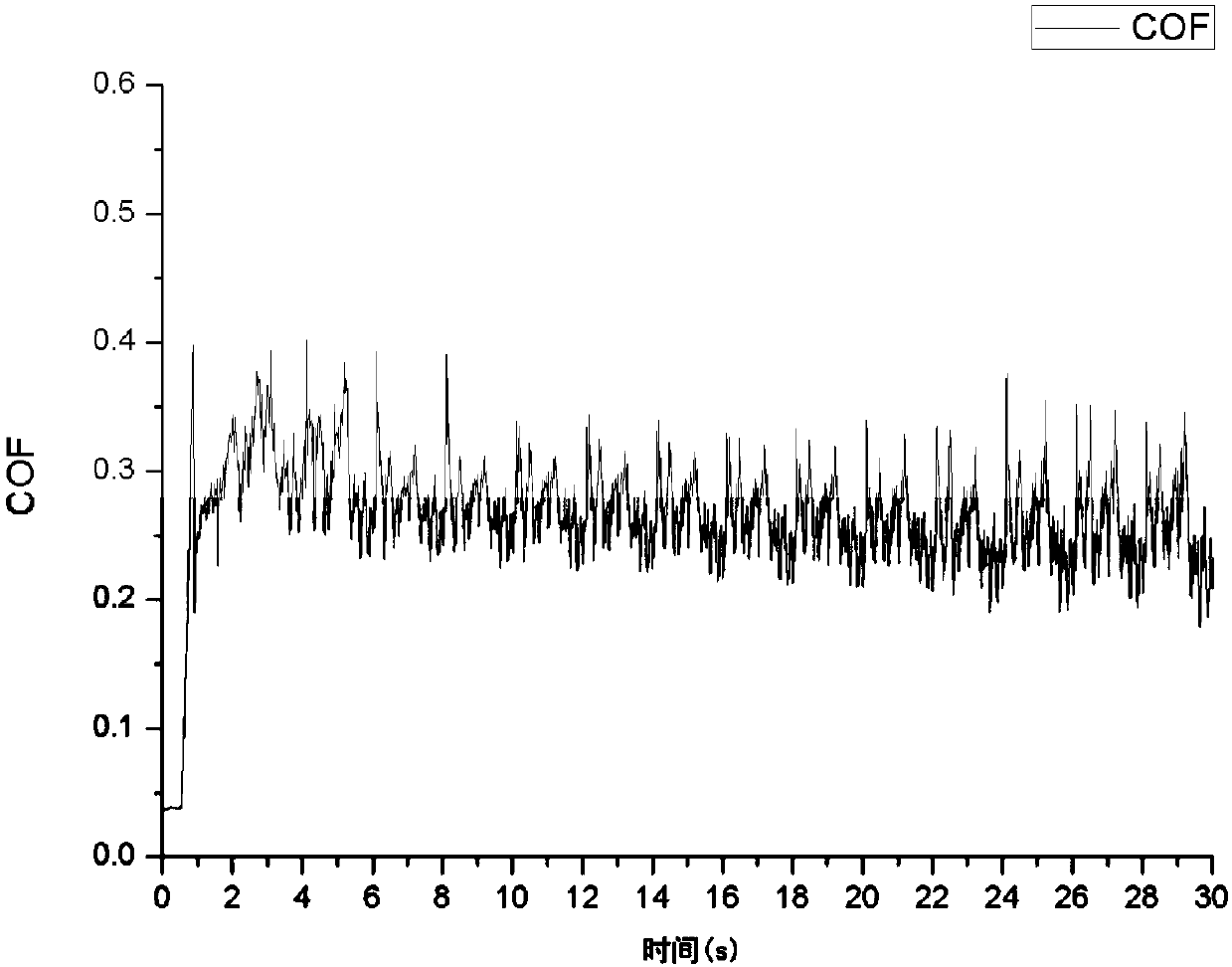

[0052] 1. Grouping and experimental methods

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a water-based lubricating agent for titanium alloy hot extrusion forming, and a preparation method of the water-based lubricating agent. The water-based lubricating agent for titanium alloy hot extrusion forming comprises the following components in parts by weight: 28 to 35 parts by weight of lubricating main agent, 45 to 55 parts of water, 5 to 10 parts of a dispersing agent and 4 to 6 parts of an adhesive, wherein the lubricating main agent comprises graphite, molybdenum disulfide and silicon dioxide; the dispersing agent is industrial alcohol and / or polyethylene glycol, lauryl sodium sulfate or sodium dodecyl sulfate. The water-based lubricating agent for titanium alloy hot extrusion forming has the characteristics of a good lubricating effect, a wide applicabletemperature range, simplicity in operation, easiness in removal, environmental friendliness, avoidance of oxidation in the high-temperature processing process of a workpiece and the like.

Description

technical field [0001] The invention relates to the field of material tribology, in particular to a water-based lubricant for hot extrusion of titanium alloys and a preparation method thereof. Background technique [0002] Due to its high specific strength, low density, good corrosion resistance and many other advantages, titanium alloy has become a high-performance new material that has attracted much attention in the fields of automobiles, ships, aerospace and other fields. However, titanium alloys have poor fluidity, high heat generation rate, severe mold sticking and easy oxidation during high temperature deformation, which brings difficulties to hot forming. The key to solving this problem is to improve the lubrication effect between the workpiece and the mold during titanium alloy processing. [0003] For the hot extrusion process of titanium alloy, there are two traditional lubrication methods: [0004] (1) Copper-clad lubrication. Cover the surface and inner hole ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M173/02C10M175/00B05D7/14B05D7/24C10N40/24C10N30/06C10N30/10C10N50/08

CPCB05D7/14B05D7/24B05D2202/35C10M173/02C10M175/00C10M2201/041C10M2201/066C10M2201/085C10M2201/087C10M2201/102C10M2201/103C10M2201/105C10M2207/021C10M2207/026C10M2207/123C10M2207/289C10M2209/104C10M2219/042C10M2219/044C10M2219/084C10M2229/041C10N2030/06C10N2030/10C10N2040/24C10N2050/08C10N2030/64C10N2040/242C10N2040/244C10N2010/12C10N2010/06C10N2010/02

Inventor 李华王岩张晨辉雒建斌

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com