Three-dimensional nano bead curtain shaped composite metal nitride/oxide and preparation method and application thereof

A composite metal and oxide technology, applied in the manufacture of hybrid/electric double layer capacitors, nanotechnology, nanotechnology, etc., to avoid the impact of capacitor performance, overcome low rate, and improve affinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

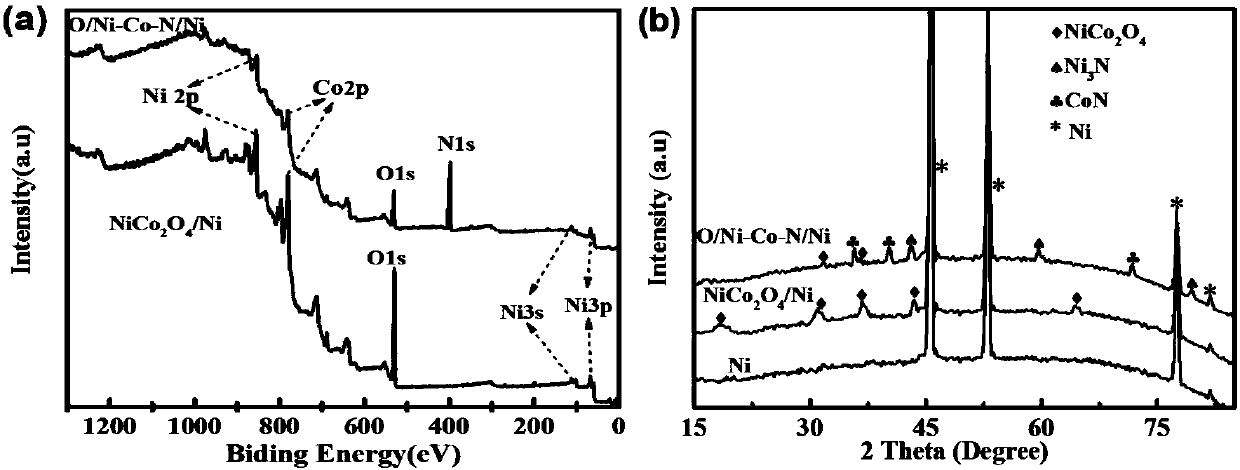

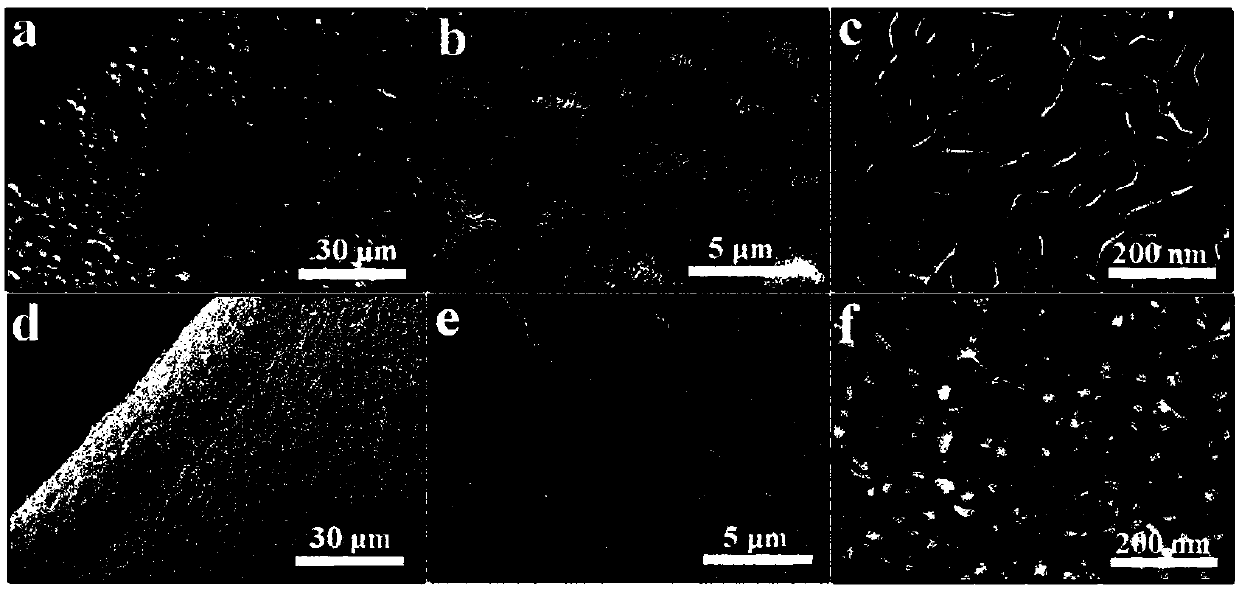

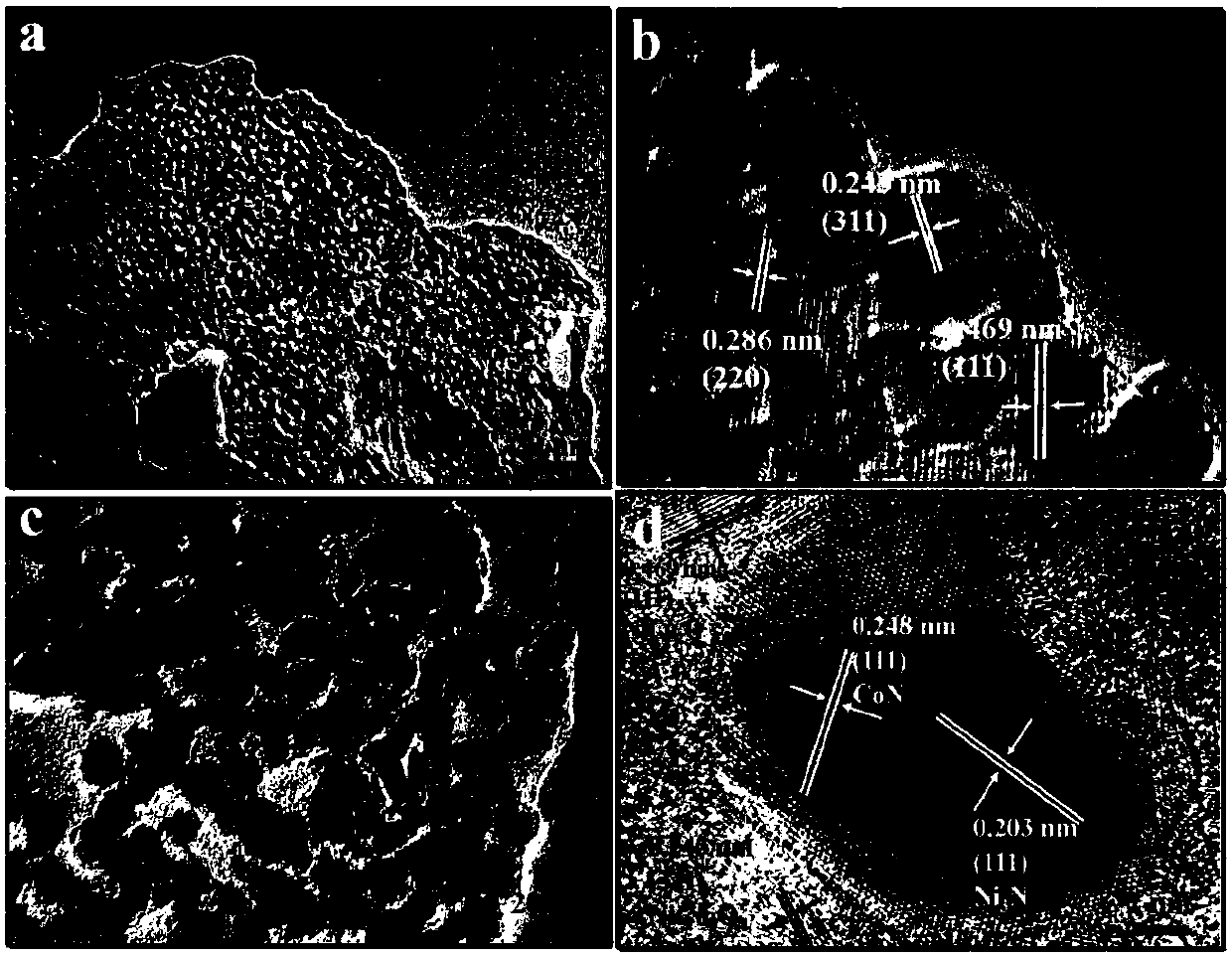

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of three-dimensional "nano-bead curtain" composite metal nitrogen / oxide, the steps are:

[0033] (1) The cobalt nitrate and nickel nitrate are mixed and dissolved in water at a molar ratio of 2:1, and the mixture is continuously stirred until the mixing is complete.

[0034] (2) Measure 40mL of the prepared mixed solution and place it in the electrolytic cell, and cut out 1×5cm 2 The foamed nickel is suspended in the mixed solution, and the infiltration area of the foamed nickel is 1×1cm 2 . The circuit is connected in a three-electrode system, and a constant voltage electrochemical deposition method is adopted, the deposition voltage is -1V, and the deposition is 10 minutes. The deposited nickel foam is repeatedly washed with deionized water to remove surface attachments and attached ions. The cleaned foamed nickel is placed in a vacuum drying oven and dried at 50°C for 24 hours.

[0035] (3) Put the dried nickel foam in a quartz crucible, place it ...

Embodiment 2

[0041] (1) The cobalt nitrate and nickel nitrate are mixed and dissolved in water at a molar ratio of 1:1, and the mixture is continuously stirred until the mixing is complete.

[0042] (2) Measure 40mL of the prepared mixed solution and place it in the electrolytic cell, and cut out 1×4cm 2 The foamed nickel is suspended in the mixed solution, the infiltration area of the foamed nickel is 1×2cm 2 . The circuit is connected in a three-electrode system, and a constant voltage electrochemical deposition method is adopted, the deposition voltage is -0.8V, and the deposition is 5 minutes. The deposited nickel foam is repeatedly washed with deionized water to remove surface attachments and attached ions. The cleaned nickel foam is placed in a vacuum drying oven and dried at 60°C for 20 hours.

[0043] (3) Put the dried nickel foam in a quartz crucible, and place it in a tube furnace in an argon atmosphere at a temperature of 2°C / min to 300°C, and keep it for 2 hours. The calcined ni...

Embodiment 3

[0045] (1) The cobalt nitrate and nickel nitrate are mixed and dissolved in water according to a molar ratio of 4:1, and are continuously stirred until the mixing is complete.

[0046] (2) Measure 50mL of the prepared mixed solution and place it in the electrolytic cell, and cut 1×8cm 2 The foamed nickel is suspended in the mixed solution, and the infiltration area of the foamed nickel is 1×3cm 2 . The circuit was connected in a three-electrode system, and a constant voltage electrochemical deposition method was used, the deposition voltage was -1V, and the deposition was 15 minutes. The deposited nickel foam is repeatedly washed with deionized water to remove surface attachments and attached ions. The cleaned nickel foam is placed in a vacuum drying oven and dried at 80°C for 10 hours.

[0047] (3) Put the dried nickel foam in a quartz crucible, and place it in a tube furnace in an argon protective atmosphere at a temperature of 2°C / min to 350°C, and keep it for 3h. The calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com