Process for purifying volatile organic waste gas

A volatile organic and waste gas purification technology, which is applied in the direction of incinerators, gas treatment, and air quality improvement, can solve the problems of expensive absorption solvents, poor pertinence, and high investment costs, and achieves wide application range, low cost, and reduced load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

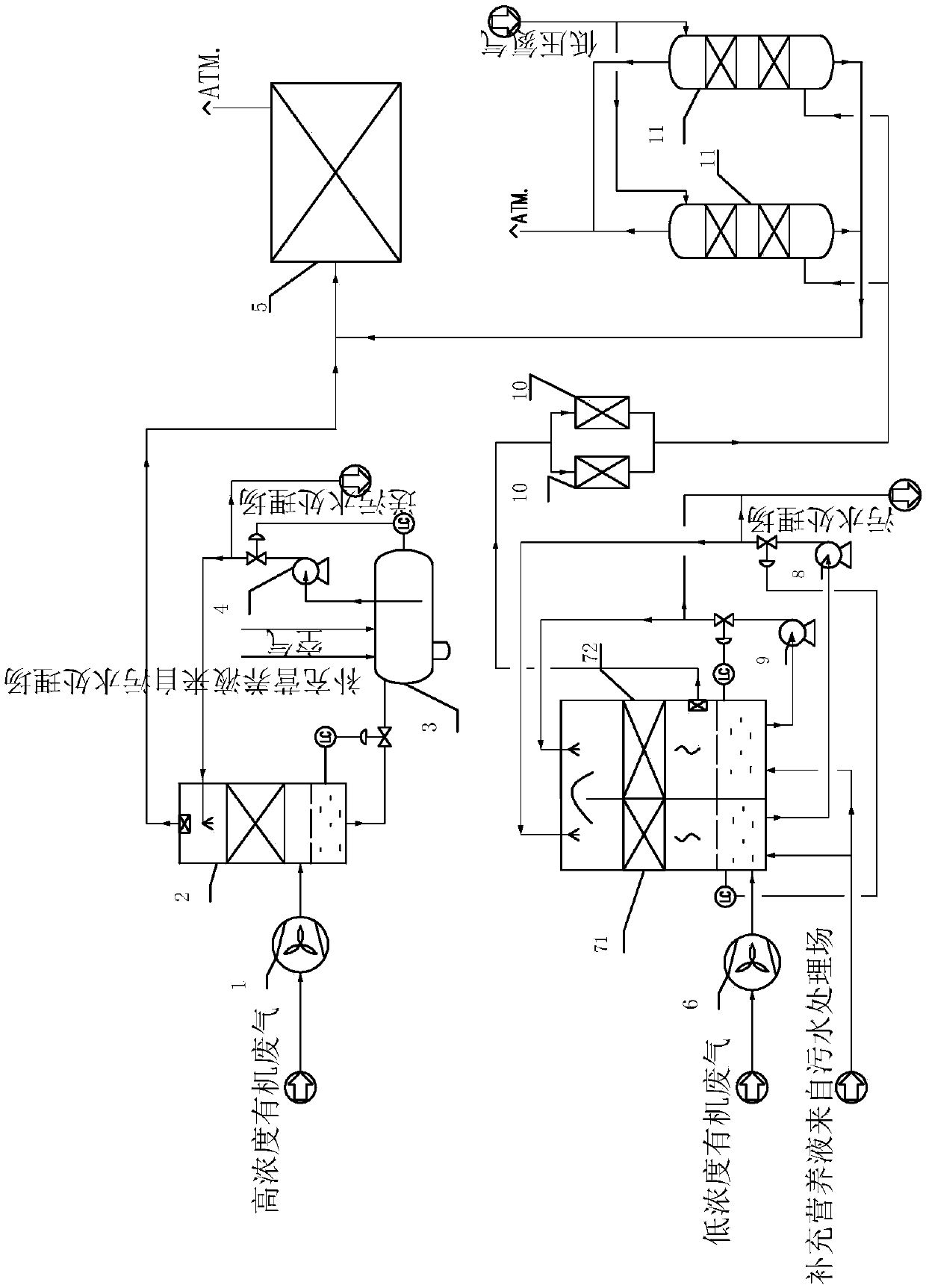

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] First, high-concentration volatile organic waste gases from structures such as waste water inlets, grease traps, flotation tanks, homogeneous tanks, and waste oil tanks, including sulfides, halides, ammonia nitrogen, olefins, aromatics, alkanes, and phenols After being scattered and collected by a closed gas collection hood, it is transported to a high-concentration waste gas treatment device by a pipeline.

[0036] Secondly, low-concentration volatile organic waste gas from structures such as aeration tanks, oxidation ditches, and sludge dewatering systems is dispersed and collected by airtight gas collection hoods, and then transported to low-concentration waste gas purification devices by pipelines.

[0037] Such as figure 1 As shown, under the suction of the blower 1, the high-concentration volatile oil from the wastewater general ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com