Deodorized detoxified fish recuperation method and deodorized detoxified fish thereof

A factory and pool water technology, applied in detoxification and detoxification (organic) fish recuperation, detoxification and detoxification (organic) fishery, fishery and aquatic products, can solve the problems of difficult to meet market demand, long organic fish breeding cycle, high cost, etc. , to achieve the effect of shortening the breeding cycle, increasing the yield per mu, and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

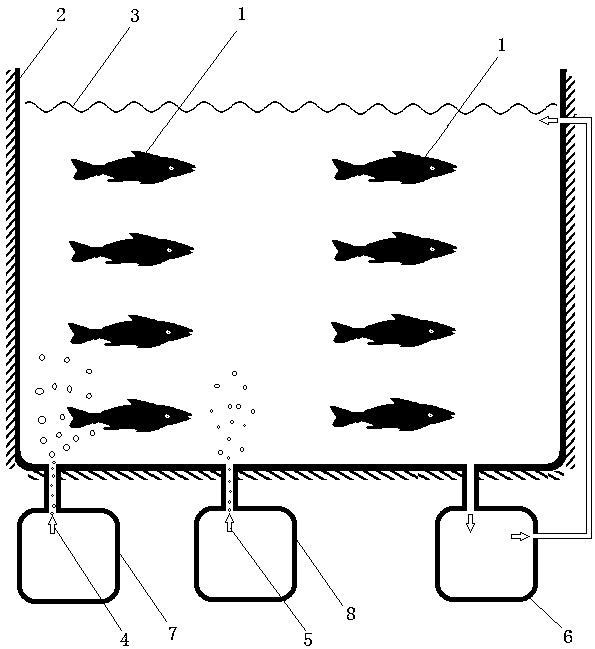

[0036] see figure 1 According to the current fish pond water circulation purification system and fish pond dissolved oxygen automatic monitoring system (see "Hebei Fishery" magazine total No. 187 for details), another commercially available ozone machine (7) is purchased to build a 15-ton capacity The factory pool (2) - also known as the water tank.

[0037] Move 3,000 live fish (freshwater fish or seawater fish) weighing 0.8 catties from the fishing ground into the 10-ton factory pool water (3) in the factory pool (2), stop / reduce food for 3-7 days, and lose weight After 1-2%, it will be shipped to the market or slaughtered and processed (for example, processed into fish meat and other foods); the purpose of stopping / reducing food is to metabolize and eliminate garbage, toxins, drug residues, heavy metals, etc. in the body.

[0038] Turn on the ozone machine (7) and pass ozone (4) into the factory pool water (3) to make the ozone concentration in the water reach 3-5mg / L, so a...

Embodiment 2

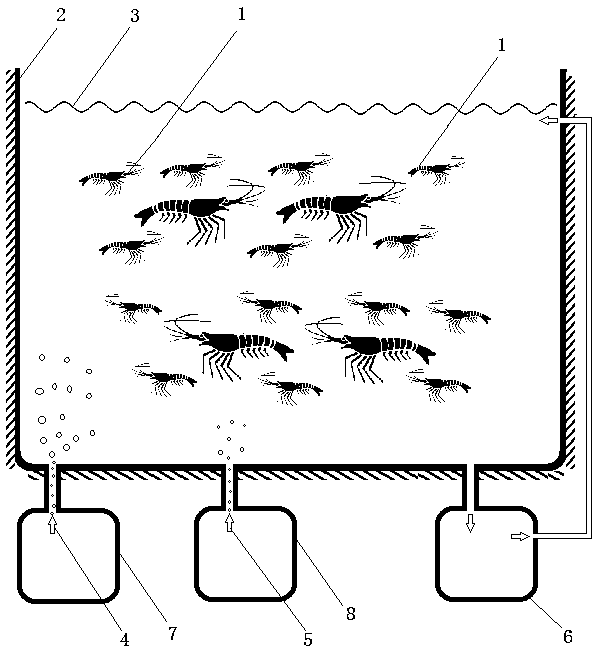

[0052] see figure 2 According to the current fish pond water circulation purification system and fish pond dissolved oxygen automatic monitoring system (see "Hebei Fishery" magazine total No. 187 for details), another commercially available ozone machine (7) is purchased to build a 15-ton capacity The factory pool (2) - also known as the water tank.

[0053] Move 10,000 pond-fed live shrimp weighing 0.1 catties from the shrimp farm into the 10-ton factory pool water (3) in the factory pool (2), stop / reduce food for 3-6 days, and lose weight by 0.5-1%. , and then leave the factory for marketing or slaughter and process (for example, processed into shrimp meat and other foods); the purpose of stopping / reducing food is to metabolize and eliminate garbage, toxins, drug residues, heavy metals, etc. in the body.

[0054] Turn on the ozone machine (7) and pass ozone (4) into the factory pool water (3) to make the ozone concentration in the water reach 3-5mg / L, so as to sterilize the...

Embodiment 3

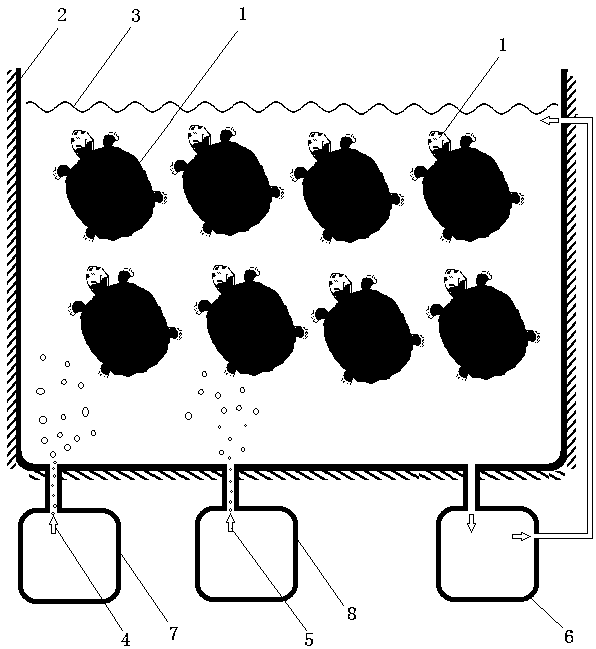

[0068] see image 3 According to the current fish pond water circulation purification system and fish pond dissolved oxygen automatic monitoring system (see "Hebei Fishery" magazine total No. 187 for details), another commercially available ozone machine (7) is purchased to build a 15-ton capacity The factory pool (2) - also known as the water tank.

[0069] Move 500 live turtles (or soft-shelled turtles) weighing 1.5 catties from the turtle farm into the 10-ton factory pool water (3) in the factory pool (2), stop / reduce food for at least 10 days, and lose weight by 0.5- After 3%, it will be shipped to the market or slaughtered and processed (for example, processed into turtle meat and other foods); the purpose of stopping / reducing food is to metabolize and eliminate garbage, toxins, drug residues, heavy metals, etc. in the body.

[0070] Turn on the ozone machine (7) to pass ozone (4) into the factory pool water (3) and make the ozone concentration in the water reach 4-5 mg / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com