Method for producing strontium chloride by means of strontium slag, and strontium chloride prepared by using method

A technology of strontium chloride and strontium slag, applied in the field of strontium chloride, can solve problems such as unstable product quality, difficult control of crystal particle size, and easy agglomeration of products, and achieve the effects of convenient feeding and discharging, simple algorithm, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

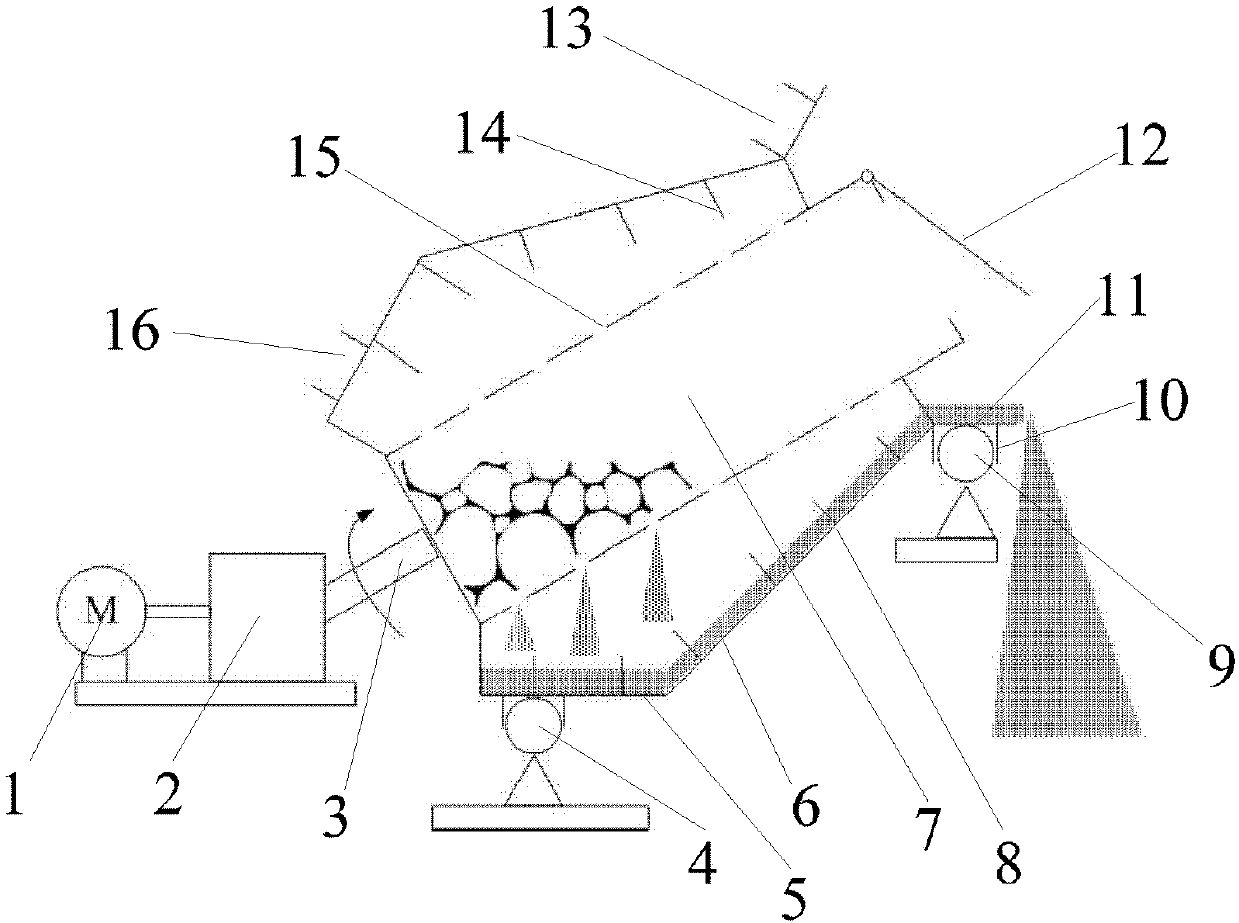

[0035] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings to make the above and other objectives, features and advantages of the present invention clearer. The same reference numerals indicate the same parts in all the drawings. The drawings are not drawn to scale deliberately, and the focus is on showing the gist of the present invention.

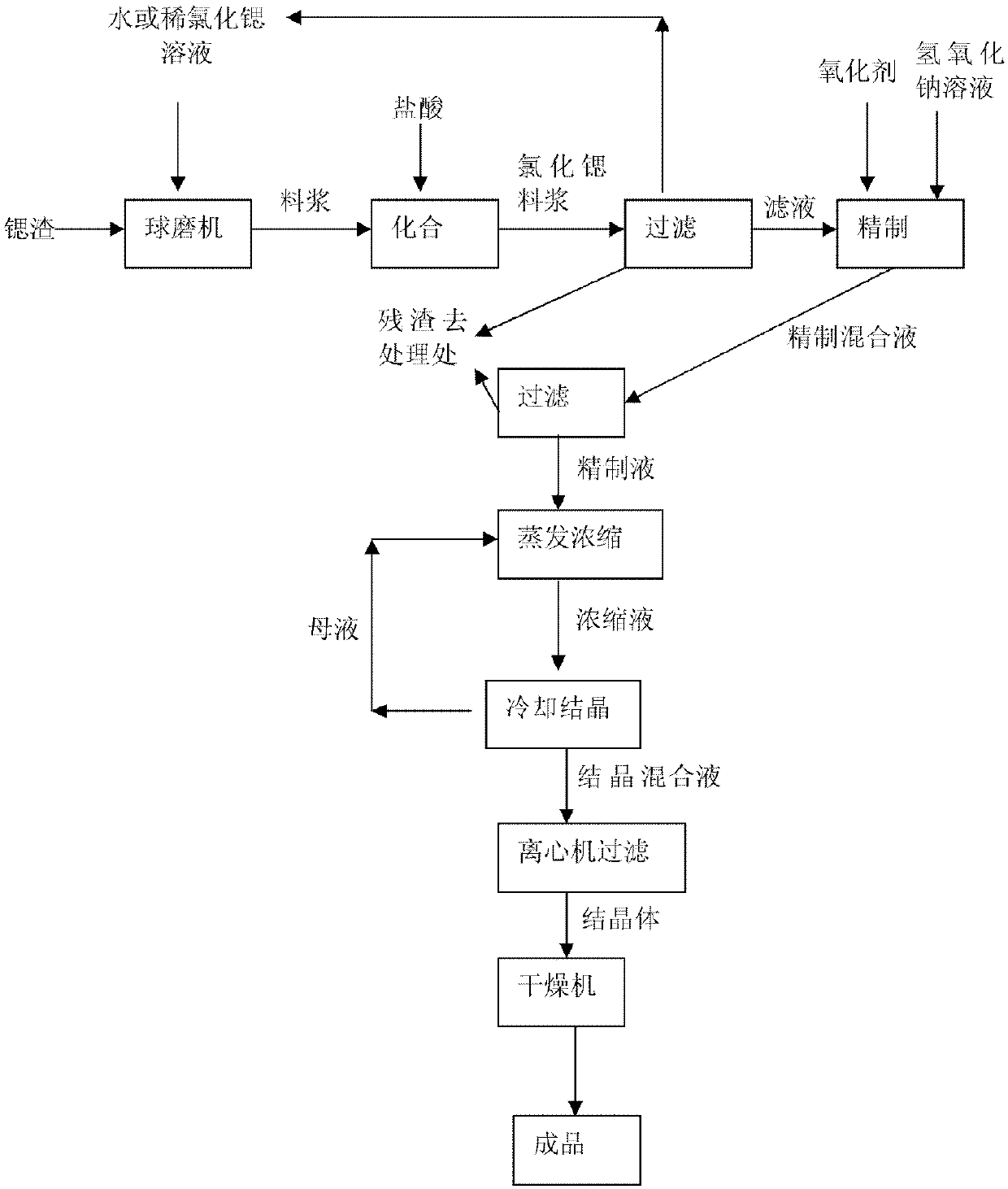

[0036] See figure 1 versus figure 2 The method for producing strontium chloride hexahydrate from strontium slag of the present invention includes the following steps.

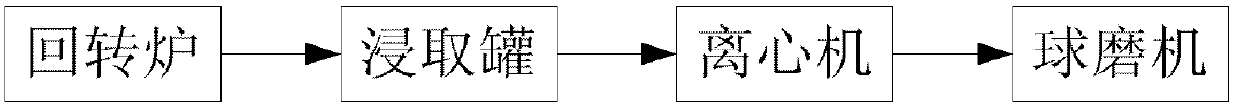

[0037] The invention discloses: S100: Celestite and raw coal are reduced and roasted in a rotary kiln under high temperature conditions, and the crude barium and strontium materials obtained by roasting are added to a closed extraction tank filled with water, and heated, pressurized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com