Method for preparing three-dimensional cell scaffold for in-vitro toxicological evaluation of tobacco products and method for cell culture by use of three-dimensional cell scaffold

A three-dimensional cell, tobacco product technology, applied in epidermal cells/skin cells, biochemical equipment and methods, cell culture supports/coatings, etc., to improve adhesion and proliferation, convenient toxicology evaluation experiments, and evaluation objective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

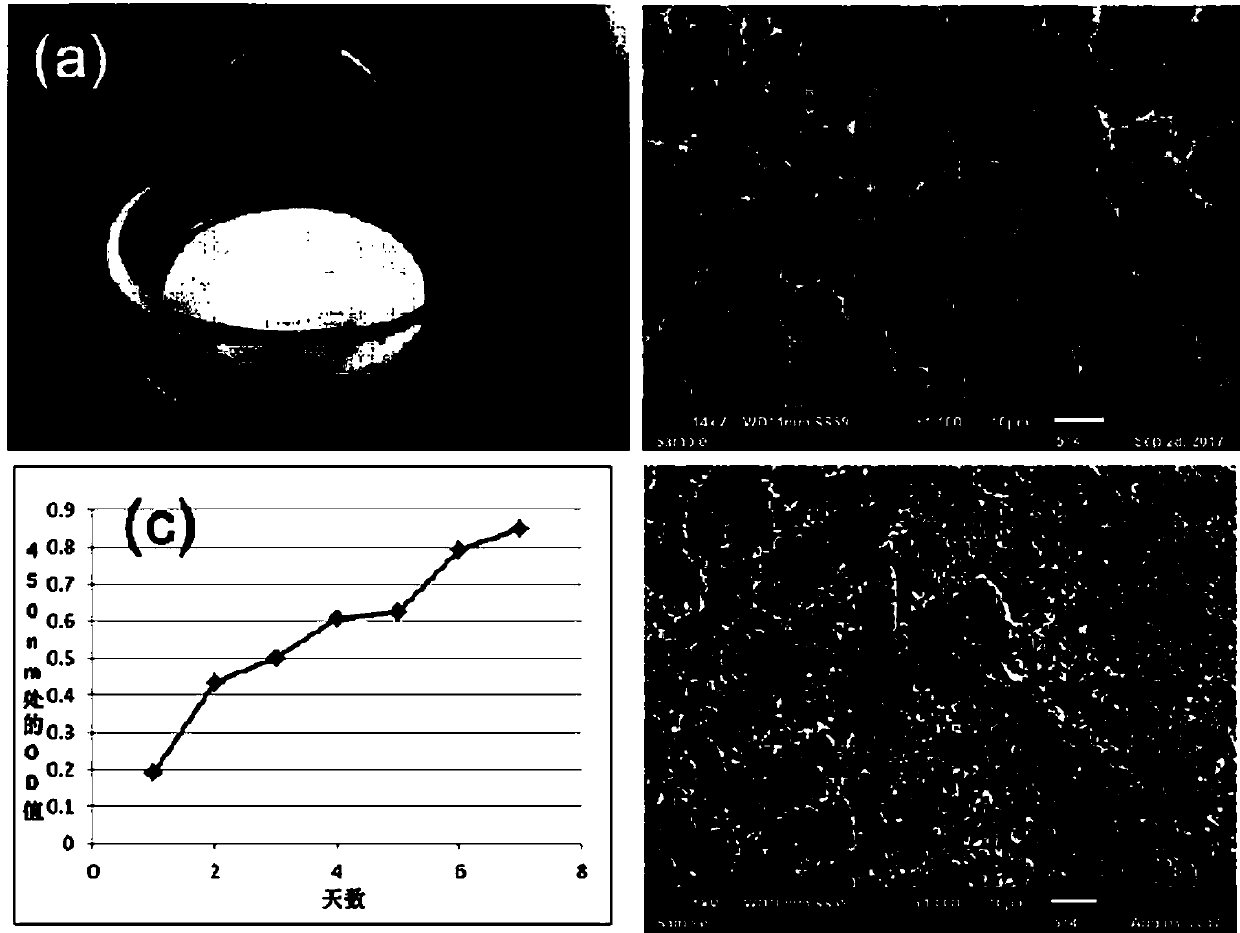

Embodiment 1

[0037] First, the oil phase was prepared to consist of 4ml of styrene, 0.5ml of divinylbenzene, and 2.4g of SPAN 80, and then the water phase was prepared to consist of 64ml of water, 0.5g of calcium chloride and 0.65g of potassium persulfate. Under high-speed stirring at 500 rpm, the water phase was slowly added to the oil phase to form a high internal phase emulsion, which was poured into a cell culture dish with a diameter of 36 mm, a height of 2 mm, and sealed after 10 min of nitrogen. It was then polymerized in an oven at 60°C for 24 hours. The samples were extracted by Soxhlet method with ethanol and water as solvent for 24 h and then dried in vacuum. L-type polylysine with a molecular weight of 70,000 to 150,000 and a concentration of 0.1 mg / ml was added to the vacuum-dried materials, and soaked for 24 hours. Then sterilized in a high-pressure steam cooker. The sterilized samples were placed in a 6-well plate, and 2 ml of 1640 medium containing 10% fetal bovine serum a...

Embodiment 2

[0039] First, the oil phase was prepared to consist of 4ml of styrene, 0.5ml of divinylbenzene, and 2.4g of SPAN 80, and then the water phase was prepared to consist of 64ml of water, 0.5g of calcium chloride and 0.65g of potassium persulfate. Under high-speed stirring at 500 rpm, the water phase was slowly added to the oil phase to form a high internal phase emulsion, which was poured into a cell culture dish with a diameter of 36 mm, a height of 2 mm, and sealed after 10 min of nitrogen. It was then polymerized in an oven at 60°C for 24 hours. The samples were extracted by Soxhlet method with ethanol and water as solvent for 24 h and then dried in vacuum. L-type polylysine with a molecular weight of 30,000 to 70,000 and a concentration of 0.1 mg / ml was added to the vacuum-dried materials, and soaked for 24 hours. Then sterilized in a high-pressure steam cooker. The sterilized samples were placed in a 6-well plate, and 2 ml of 1640 medium containing 10% fetal bovine serum an...

Embodiment 3

[0041] First, the oil phase was prepared to consist of 4ml of styrene, 0.5ml of divinylbenzene, and 2.4g of SPAN 80, and then the water phase was prepared to consist of 64ml of water, 0.5g of calcium chloride and 0.65g of potassium persulfate. Under high-speed stirring at 500 rpm, the water phase was slowly added to the oil phase to form a high internal phase emulsion, which was poured into a cell culture dish with a diameter of 36 mm, a height of 2 mm, and sealed after 10 min of nitrogen. It was then polymerized in an oven at 60°C for 24 hours. The samples were extracted by Soxhlet method with ethanol and water as solvent for 24 h and then dried in vacuum. D-type polylysine with a molecular weight of 30,000 to 70,000 and a concentration of 0.1 mg / ml was added to the vacuum-dried materials, and soaked for 24 hours. Then sterilized in a high-pressure steam cooker. The sterilized samples were placed in a 6-well plate, and 2 ml of 1640 medium containing 10% fetal bovine serum an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com