Method and equipment of high-pressure refrigeration of fresh food by using liquid carbon dioxide

A technology of liquid carbon dioxide and refrigeration equipment, which is applied in the direction of freezing/cooling preservation of meat/fish, etc., which can solve the problems of inability to use direct contact with food, limit the application range of high hydrostatic pressure freezing, and pressure resistance damage, etc., to achieve the suppression of ice crystals The effect of growth, shortening of freezing time, and short gasification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

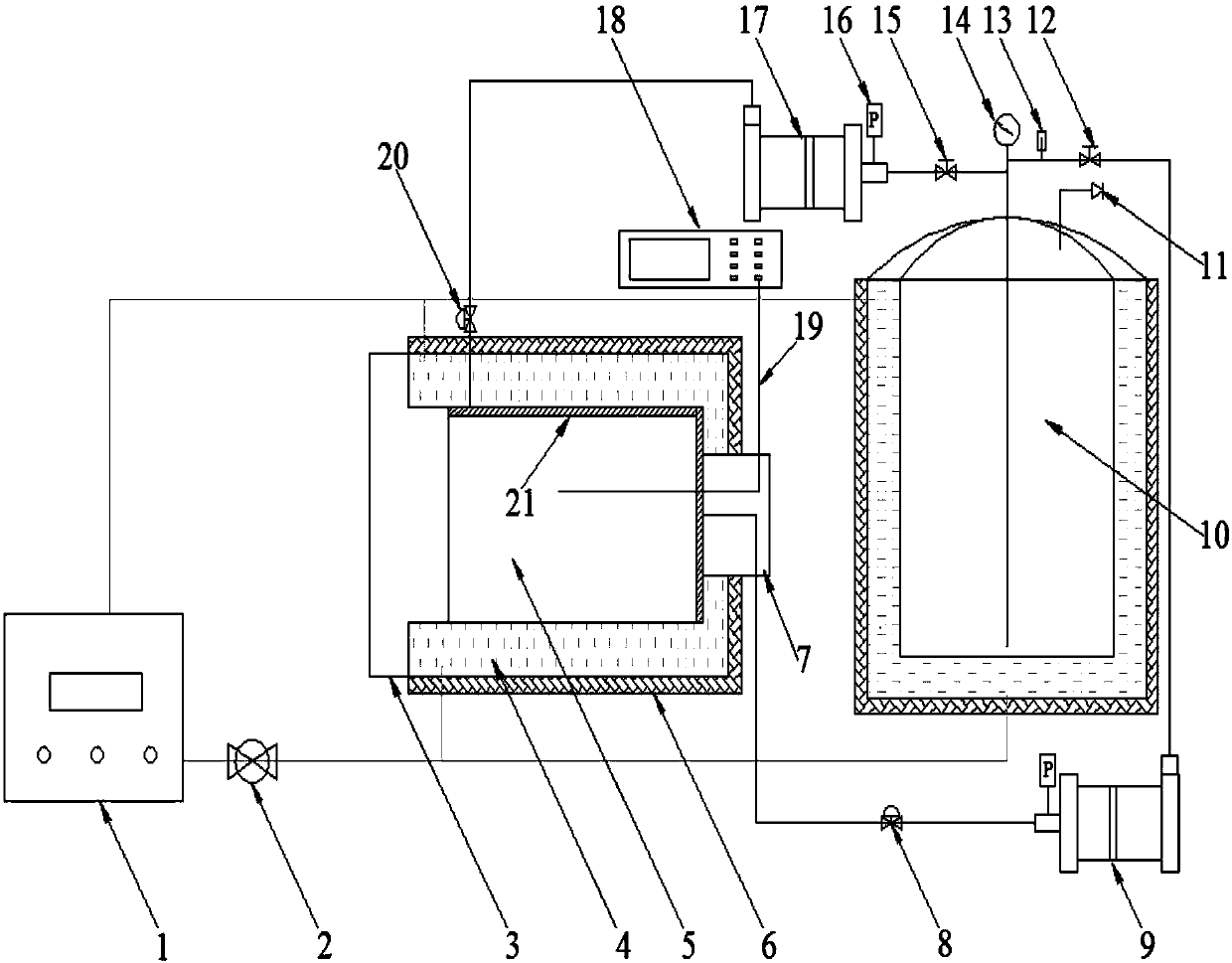

[0078] Utilize above-mentioned refrigeration equipment to realize the method for liquid carbon dioxide high-pressure freezing fish meat, specifically comprise the following steps:

[0079] (1) Turn on the refrigeration temperature control system and control the temperature of the refrigerant at -19°C. The liquid carbon dioxide in the chamber of the high-pressure refrigeration device and the liquid carbon dioxide storage tank has been pre-cooled under the action of the refrigerant. The sample chamber (i.e. chamber) The temperature and the temperature of liquid carbon dioxide both reach -19°C, ready to be put into fresh food;

[0080] (2) Select the grass carp (3-4Kg / piece) that is often eaten, remove the viscera, clean it, wipe off the water stains on the surface, and place it in the pre-cooled sample chamber, and place the thermocouple at the geometric center of the fish; close The first plug, close the shut-off valve 1, open the shut-off valve 2, the booster pump 1 and the pr...

Embodiment 2

[0084] The method for liquid carbon dioxide high pressure freezing fish of the present embodiment specifically comprises the following steps:

[0085] (1) Turn on the refrigeration cycle temperature control system to reduce the temperature of the refrigerant to -14°C. The cavity of the high-pressure freezer and the liquid carbon dioxide in the liquid carbon dioxide storage tank are pre-cooled under the action of the refrigerant. The sample chamber (i.e., the chamber ) and liquid carbon dioxide both reach -14°C;

[0086] (2) Select tilapias of moderate size (1-2Kg / piece), wipe off the water stains on the surface and place them in the pre-cooled sample chamber, place the thermocouple at the geometric center of the fish; quickly close the first plug , close the shut-off valve 1, open the shut-off valve 2, the booster pump 1 and the pressurization valve (ie booster valve) in turn, so that the low-temperature liquid carbon dioxide enters the sample chamber, and under the action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com