Modified loaded potassium carbonate absorbent and application thereof to carbon dioxide removal in impurity atmosphere

A potassium carbonate, load-type technology, applied in gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems of reduced activity of absorbents, complex air components in closed cabins, etc., to achieve improved stability and renewable cycles The effect of high utilization rate and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In this embodiment, the method of water vapor pretreatment activation is used to modify the supported potassium carbonate absorbent K 2 CO 3 / AC to increase its 2 / NO 2 Decarburization activity and stability in acidic impurity atmosphere, specifically:

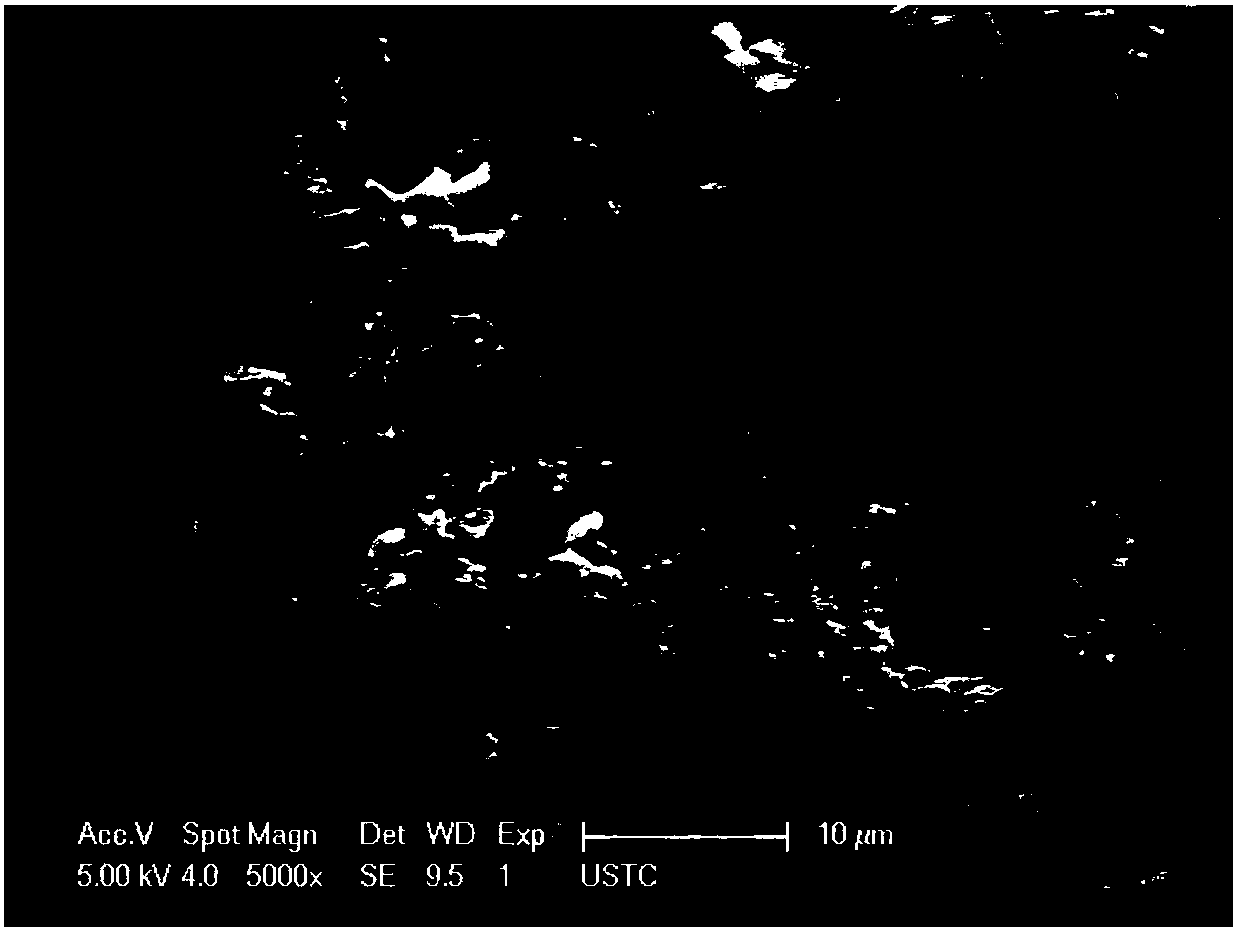

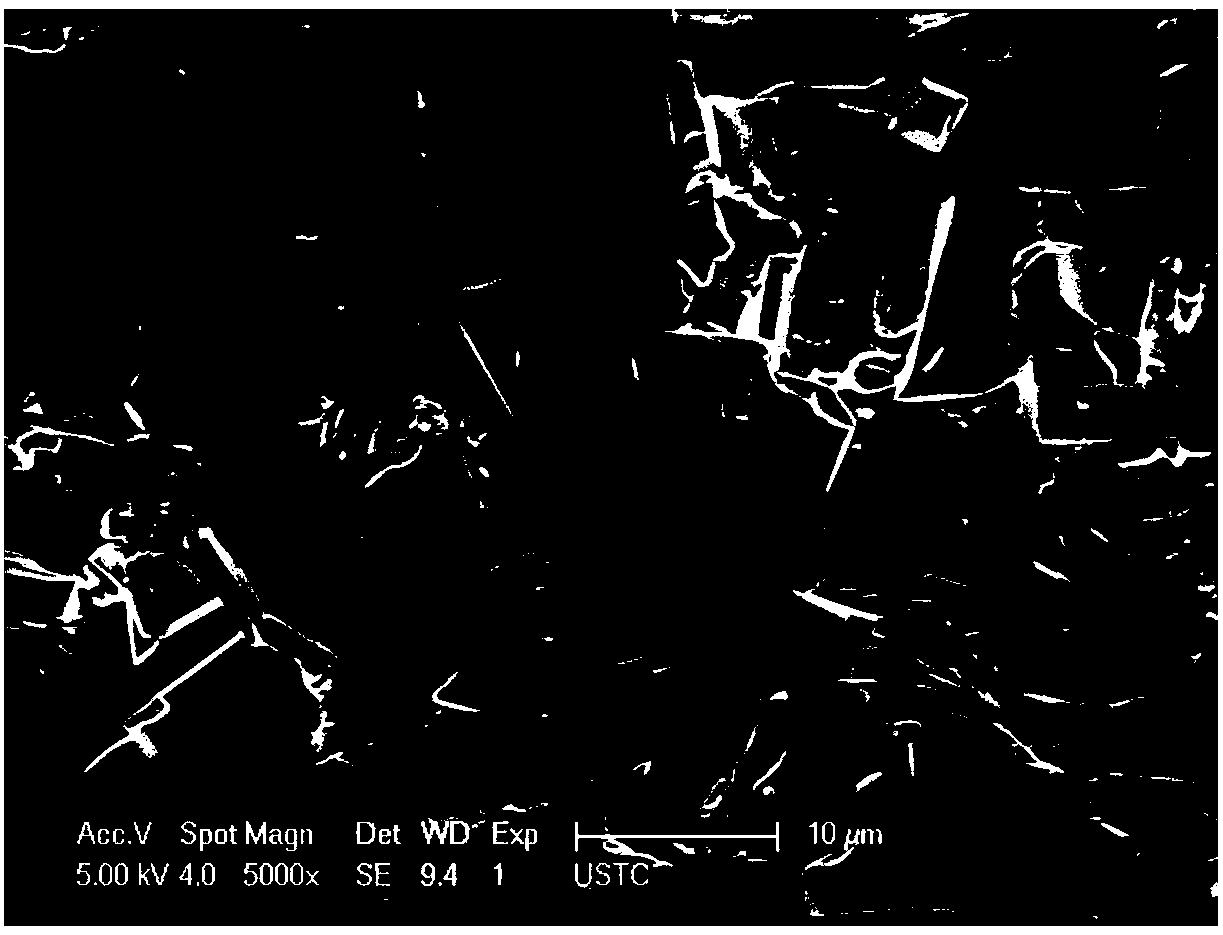

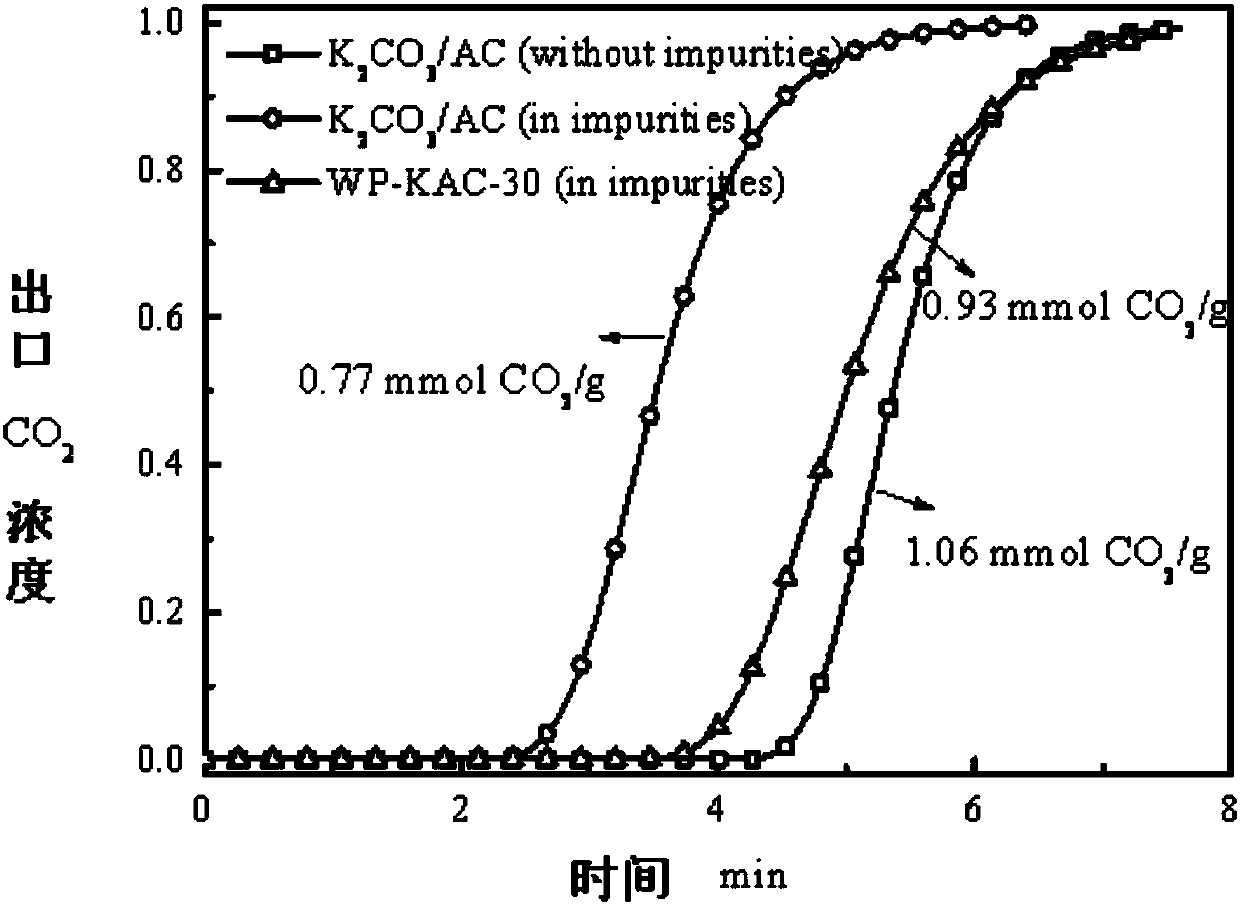

[0062] Take 5g of the loaded potassium carbonate absorbent K with a load of 15% 2 CO 3 / AC is placed in the reactor, the compressed air flows through the bubbling device at 500mL / min, and the water vapor with a temperature of 20℃ and a concentration of 2% flows into the reactor. The above-mentioned absorbent is pretreated and activated for 30 minutes to make the active group Min K 2 CO 3 Activated to stable K 2 CO 3 ·1.5H 2 O, the modified supported potassium carbonate absorbent is obtained. figure 1 It is a scanning electron micrograph of the loaded potassium carbonate absorbent in Example 1 of the present invention. figure 2 It is a scanning electron micrograph of the absorbent modified by water vapor pretreatment in Exam...

Embodiment 2

[0072] This embodiment combines the method of high-temperature steam regeneration and activation to increase the load-type potassium carbonate absorbent K 2 CO 3 / AC contains SO 2 / NO 2 Decarburization activity and stability in acidic impurity atmosphere, specifically:

[0073] Take 5g of the loaded potassium carbonate absorbent K with a load of 15% 2 CO 3 / AC is placed in the reactor, and the decarburization reaction is completed according to the water vapor pretreatment activation step in Example 1. The liquid water flows through the steam generator and generates water vapor with a temperature of 120°C through temperature control. It is mixed with compressed air (500mL / min) to form high-temperature steam with a concentration of 10%; the generated high-temperature steam is passed into the reactor to prevent carbonation. The modified absorbent is regenerated and activated for 30 minutes to make the carbonated product KHCO 3 Activated to stable K 2 CO 3 ·1.5H 2 O.

[0074] When the ...

Embodiment 3

[0077] In order to better illustrate the technical effect of the high-temperature steam regeneration activation method provided in Example 2, it is given that the absorbent after regeneration in an air atmosphere contains SO 2 / NO 2 The decarburization activity and stability under acidic impurity atmosphere, specifically:

[0078] Take 5g of the loaded potassium carbonate absorbent K with a load of 15% 2 CO 3 / AC is placed in the reactor, and the decarburization reaction is completed according to the water vapor pretreatment activation step in Example 1. Compressed air flows into the reactor at 500 mL / min, and the bed is heated to 120° C. at 10° C. / min, and then the bed temperature is maintained for 30 minutes to regenerate the carbonation absorbent. Then the reactor temperature was reduced to 20°C and the atmosphere was switched to 1.0% CO 2 , 2.0% H 2 O, 30ppm SO 2 And 20ppm NO 2 Carburize reaction.

[0079] Evaluation of decarburization effect: K regenerated under air atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com