Oxygen-enriched combustion-supporting thick oil well gas injection system and gas injection method

An oxygen-enriched combustion-supporting and oxygen-enriched air technology, applied in earth-moving drilling, wellbore/well components, production fluids, etc. The effect of equipment life, reduction of heat loss, and expansion of heating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Inject light oil / diesel oil into the light oil chamber of the light / heavy oil integrated self-heating oil tank, inject the heavy oil produced from the oil well (with a viscosity of 3000mpa·s at room temperature) into the heavy oil in the light / heavy oil integrated self-heating oil tank cavity;

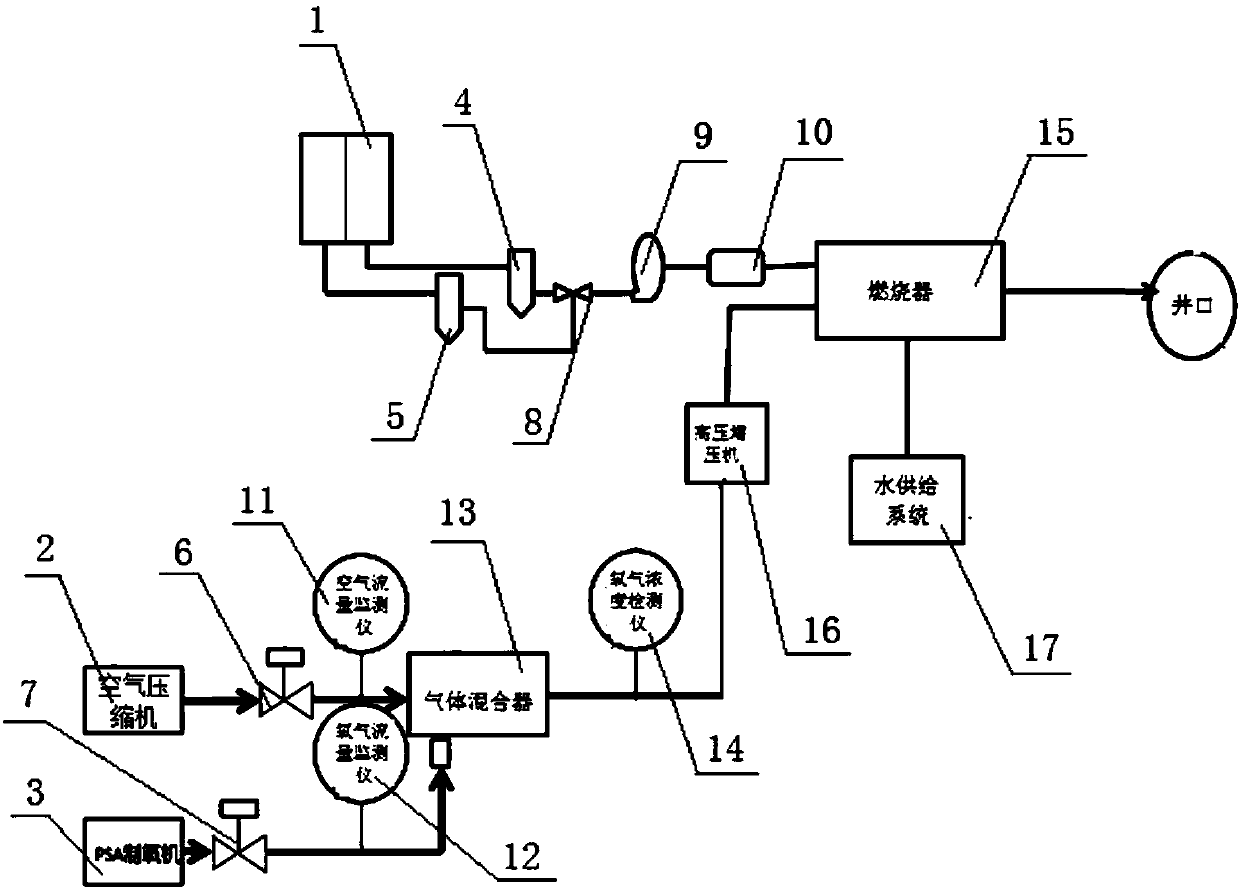

[0043] 2) Open the air flow solenoid valve and the oxygen flow solenoid valve, start the air compressor, pressure swing adsorption oxygen generator and water supply system, so that the prepared oxygen-enriched air is pressurized by the high-pressure booster and then sent to the burner, and the water Enter the burner through the water supply system; when the system is ignited, switch the switch valve to the light oil / diesel pipeline, inject the light oil / diesel into the burner through the high-pressure oil pump and mix it with 25% oxygen-enriched air for combustion, and mix with water After contact heat exchange and gasification, the multivariate thermal fluid (that is, the mi...

Embodiment 2

[0047] 1) Inject light oil / diesel oil into the light oil chamber of the light / heavy oil integrated self-heating oil tank, inject No. 180 heavy oil into the heavy oil chamber of the light / heavy oil integrated self-heating oil tank;

[0048] 2) Open the air flow solenoid valve and the oxygen flow solenoid valve, start the air compressor, pressure swing adsorption oxygen generator and water supply system, so that the prepared oxygen-enriched air is pressurized by the high-pressure booster and then sent to the burner, and the water Enter the burner through the water supply system; when the system is ignited, switch the switching valve to the light oil / diesel pipeline, inject the light oil / diesel into the burner through the high-pressure oil pump and mix it with oxygen-enriched air with 28% oxygen content for combustion, and mix with water After contact heat exchange and gasification, the multivariate thermal fluid (that is, the mixture of flue gas, water vapor and water) produced i...

Embodiment 3

[0052] 1) Inject light oil / diesel oil into the light oil cavity of the light / heavy oil integrated self-heating oil tank, inject the heavy oil produced from the heavy oil well (12000mpa·s at room temperature) into the light / heavy oil integrated self-heating oil tank in the heavy oil chamber;

[0053] 2) Open the air flow solenoid valve and the oxygen flow solenoid valve, start the air compressor, pressure swing adsorption oxygen generator and water supply system, so that the prepared oxygen-enriched air is pressurized by the high-pressure booster and then sent to the burner, and the water Enter the burner through the water supply system; when the system is ignited, switch the switch valve to the light oil / diesel pipeline, inject the light oil / diesel into the burner through the high-pressure oil pump and mix it with 30% oxygen-enriched air for combustion, and mix with water After contact heat exchange and gasification, the multivariate thermal fluid (that is, the mixture of flue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com