A heavy metal detection device and detection method thereof

A detection device and heavy metal technology, applied in the field of sensors, can solve the problems of poor long-term stability and poor measurement accuracy, achieve the effect of reinforcement firmness, optimized detection process, and long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

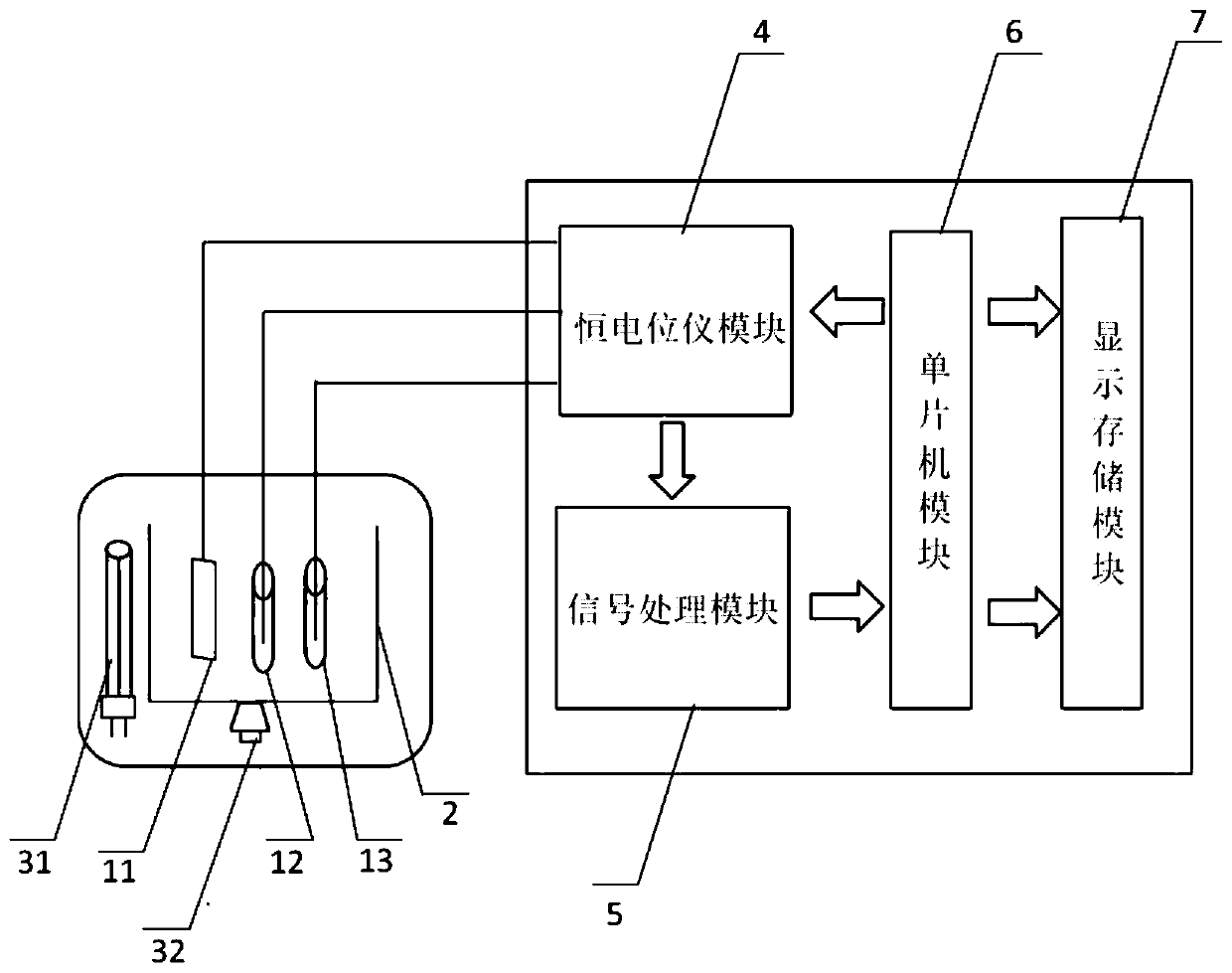

[0035] Such as figure 1 As shown, the present invention provides a heavy metal detection device integrating photocatalytic reduction and ultrasonic-assisted heavy metal detection device.

[0036] Such as figure 1 As shown, the heavy metal detection device includes: a sensor device, a reaction pool device 2, an auxiliary system, a potentiostat module 4, a signal processing module 5, a single-chip microcomputer module 6 and a display storage module 7.

[0037] The sensor device is arranged in the reaction pool device 2, and the reaction pool device 2 is used to contain the liquid to be tested containing heavy metal ions. Described sensor device comprises working electrode 11, described reference electrode 12 and described counter electrode 13, and described working electrode 11, reference electrode 12 and described counter electrode 13 are connected with described potentiostat, and described working electrode 11 is A titanium sheet loaded with a titanium dioxide nanotube array...

Embodiment 2

[0047] The present invention provides a method for preparing a heavy metal detection device, the method for preparing a working electrode 11 of a sensor device in the heavy metal detection device comprises the following steps:

[0048] Step S1: Before using the two-electrode method for anodic oxidation reaction, polish the titanium sheet substrate in a chemical polishing solution, and ultrasonically clean the polished titanium sheet substrate in acetone, absolute ethanol, and deionized water for 15 to 25 minutes respectively, Blow dry and set aside. In a preferred embodiment, the polishing liquid includes HF, HNO with a volume ratio of 1:4:5 3 and H 2 O.

[0049] Step S2: Carry out anodic oxidation reaction by two-electrode method, put the titanium substrate into the electrolyte, and place a platinum wire on both sides of the titanium substrate, which is conducive to the uniform growth of titanium dioxide nanotubes on the surface of the titanium substrate. In this embodimen...

Embodiment 3

[0055] This embodiment provides a detection method of a heavy metal detection device, the detection method of the heavy metal detection device includes:

[0056] Step 1: Connect the working electrode 11, the reference electrode 12 and the counter electrode 13 of the sensor device to the potentiostat module 4 of the heavy metal detection device through wires.

[0057] Step 2: Put the liquid to be tested into the reaction cell device 2, immerse the working electrode 11, the reference electrode 12 and the counter electrode 13 in the solution to be tested, turn on the excitation light source 31 and the ultrasonic device 32 to digest the liquid to be tested, so that The heavy metal ions complexed by the organic matter are fully released, and the heavy metal ions are photocatalytically reduced to zero-valent heavy metal simple substances on the surface of the working electrode 11 , and deposited on the surface of the working electrode. In this embodiment, the liquid to be tested is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com