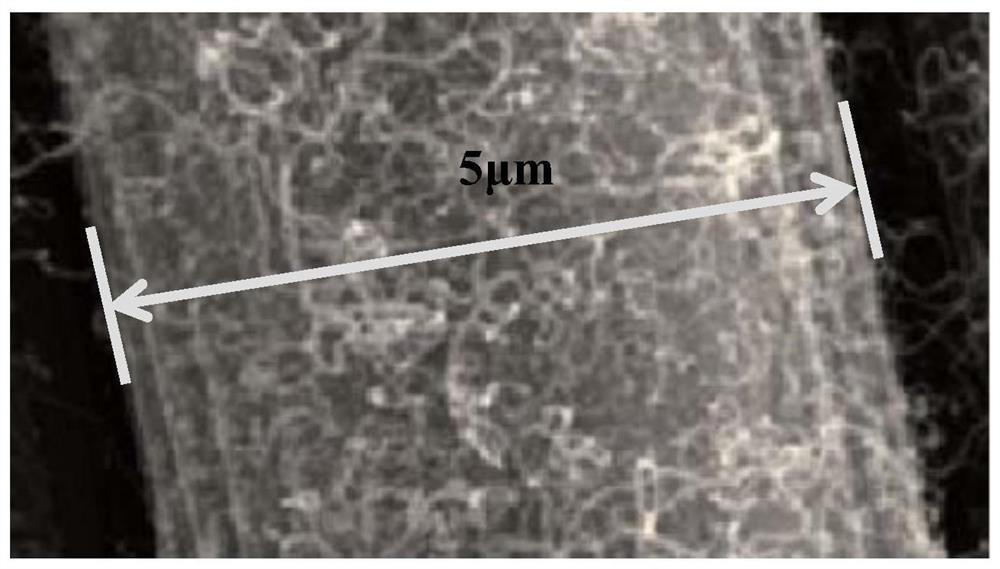

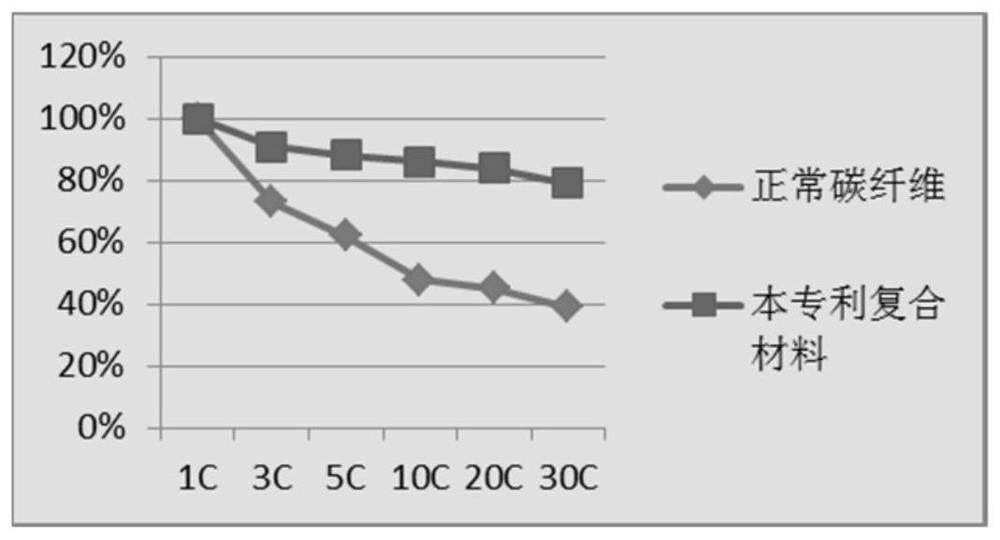

One-dimensional carbon fiber/carbon nanotube composite material, its preparation method and application

A carbon nanotube, composite material technology, used in structural parts, electrical components, battery electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] (1) Add the organic high molecular polymer PVP into the solvent NMP to obtain a dispersion liquid with a solid content of 1%.

[0068] (2) Mix the powders of carbon nanotubes (CNT) and carbon fibers (CF) according to the mass ratio of 0.1:99.9, so that the two are uniformly dispersed to obtain a mixed powder, and the mixed powder is mixed with the dispersion liquid of step (1) , so that the solid content of the resulting conductive paste was 3%.

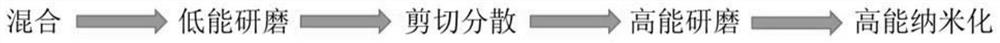

[0069] (3) The conductive paste of step (2) is first passed through low-energy ball milling. The equipment used in low-energy ball milling is a vertical ball mill, and the grinding balls are zirconium balls and ceramic balls with a size of 5mm-6mm. Ball milling time 4h.

[0070] (4) Then undergo shear dispersion, the shear speed is 1500 rpm, and the shear dispersion time is 1 h.

[0071] (5) After high-energy ball milling, the equipment used in high-energy ball milling is a horizontal fine mill, and the grinding balls are zi...

Embodiment 2

[0078] (1) The mixture of organic high molecular polymer PVP and PVDF is added to solvent H 2 O, a dispersion with a solid content of 5% was obtained.

[0079] (2) Putting carbon nanotubes (CNTs) into a part of the dispersion in step (1) to obtain a slurry of carbon nanotubes with a solid content of 5%.

[0080] (3) The slurry of the carbon nanotubes in step (2) is first passed through low-energy ball milling. The equipment used in low-energy ball milling is a vertical ball mill, and the grinding balls are zirconium balls and ceramic balls with a size of 10mm-20mm. 70Hz, low-energy ball milling time 8h; then after shear dispersion, the shear speed is 4000rpm, and the shear dispersion time is 1h; after high-energy ball milling, the equipment used for high-energy ball milling is a horizontal fine mill, and the size of the grinding balls is 0.4 mm-0.6mm zirconium balls and ceramic balls, etc., the speed of high-energy ball milling is 1000rpm, and the time of high-energy ball mil...

Embodiment 3

[0086] (1) Add the organic high molecular polymer PE into the solvent NMP to obtain a dispersion liquid with a solid content of 0.1%.

[0087] (2) Mix the powder of carbon nanotube (CNT) and carbon fiber (CF) according to the mass ratio of 1:99, make the two disperse evenly to obtain mixed powder, mix the mixed powder with the dispersion liquid of step (1) , so that the solid content of the resulting conductive paste was 16%.

[0088] (3) The conductive paste of step (2) is first passed through low-energy ball milling. The equipment used in low-energy ball milling is a vertical ball mill, and the grinding balls are zirconium balls and ceramic balls with a size of 8mm-10mm. Ball milling time 12.5h.

[0089] (4) Then undergo shear dispersion, the shear speed is 1300rpm, and the shear dispersion time is 1.5h.

[0090] (5) After high-energy ball milling, the equipment used in high-energy ball milling is a horizontal fine mill, and the grinding balls are zirconium balls and ceram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com