Compound herbicide containing s-metolachlor and preparation method of compound herbicide

A technology of refined metolachlor and herbicides, applied in the field of compound herbicides containing refined metolachlor and its preparation, which can solve the problems of outstanding weed resistance, weed damage, and the development of herbicide active ingredients The speed can not solve the problem, so as to achieve the effect of low cost of spraying and avoiding drug resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

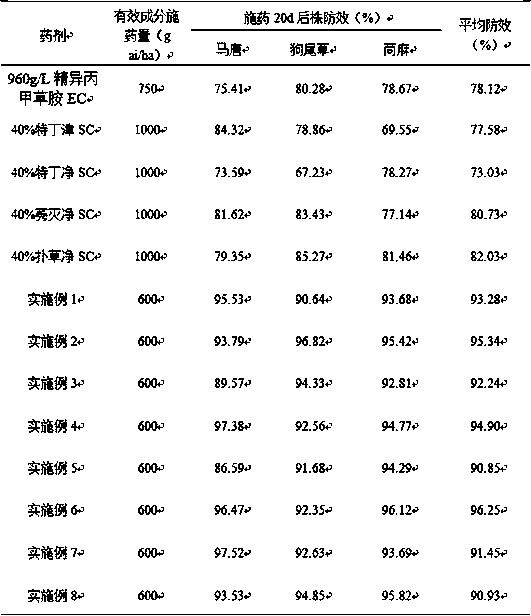

Examples

Embodiment 1

[0041] Embodiment 1: The compound herbicide containing refined metolachlor is a suspoemulsion of active ingredients composed of 10% refined metolachlor and terbuthylazine:

[0042] Purified metolachlor 2%, terbuthylazine 8%, Tween-80 6%, calcium dodecylbenzene sulfonate 3%, Solvesso-150 10%, polystyrylphenol ethoxylate sulfate 4 %, alkyl naphthalene sulfonate wetting agent 2%, ethylene glycol 3%, diethanolamine 0.3%, benzisothiazolinone 0.1%, bentonite 1%, silicone defoamer 0.2%, water supplement to 100%. In a designated container, add pure metolachlor, Tween-80, calcium dodecylbenzene sulfonate, Solvesso-150 in proportion and mix well to form an oil phase; in another container, add tertidine in proportion Hydrogen, polystyrylphenol polyoxyethylene ether sulfate, alkyl naphthalene sulfonate wetting agent, ethylene glycol, diethanolamine, benzisothiazolinone, silicone defoamer, water and stir to mix evenly for the water phase. Pour all the oil phase into the water phase, she...

Embodiment 2

[0043] Embodiment 2: The compound herbicide containing refined metolachlor is a suspoemulsion of 41% refined metolachlor and terbuthine to form active ingredients:

[0044]40% of refined metolachlor, 1% of terbutin, 5% of 600#, 8% of 700#, 15% of Solvesso-100, 3% of polycarboxylate dispersant, fatty alcohol polyoxyethylene wetting agent 1%, glycerol 3%, magnesium aluminum silicate 0.5%, xanthan gum 0.1%, sodium benzoate 0.2%, mineral oil defoamer 0.2%, ammonia water 0.2%, water to 100%. In a designated container, add metolachlor, 600#, 700#, Solvesso-100 in proportion and stir evenly to obtain the oil phase; in another container, add terbuthylazine and polycarboxylates in proportion Dispersant, fatty alcohol polyoxyethylene wetting agent, glycerol, magnesium aluminum silicate, sodium benzoate, mineral oil defoamer, ammonia and water, and stir evenly to obtain a water phase. Pour all the oil phase into the water phase, shear and homogenize on a high-speed homogeneous shear for...

Embodiment 3

[0045] Example 3: The compound herbicide containing refined metolachlor is a suspoemulsion of active ingredients composed of 60% refined metolachlor and ametryn:

[0046] 35% of refined metolachlor, 25% of ametryn, castor oil polyoxyethylene ether emulsifier 6%, 601 4%, turpentine 6%, EO / PO block copolymer 2%, lignosulfonate 3% dispersant, 1% alkylnaphthalene sulfonate wetting agent, 5% urea, 0.5% carboxyalkyl cellulose, 0.1% Cathone, 0.2% sodium hydroxide, 0.2% alcohol defoamer, Water was made up to 100%. In a designated container, add refined metolachlor, castor oil polyoxyethylene ether emulsifier, 601, and turpentine in proportion, stir and mix evenly to form an oil phase; Add ametryn, EO / PO block copolymer, lignosulfonate dispersant, alkylnaphthalene sulfonate wetting agent, urea, kathone, sodium hydroxide, alcohol defoamer and water, Stir to mix evenly into the water phase. Pour all the oil phase into the water phase, shear and homogenize on a high-speed homogeneous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com