Chlorine refining production apparatus

A production device, chlorine gas technology, applied in fractional distillation, separation methods, inorganic chemistry, etc., to achieve the effect of high purity, less impurity content, and increased power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

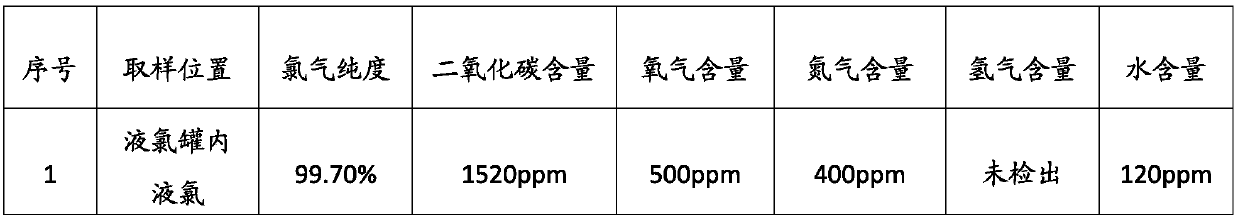

Examples

Embodiment Construction

[0021] In the following, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings. Based on these detailed descriptions, those skilled in the art can clearly understand the present invention and can implement the present invention. Without violating the principle of the present invention, the features in various embodiments can be combined to obtain new implementations, or to replace some features in some embodiments to obtain other preferred implementations.

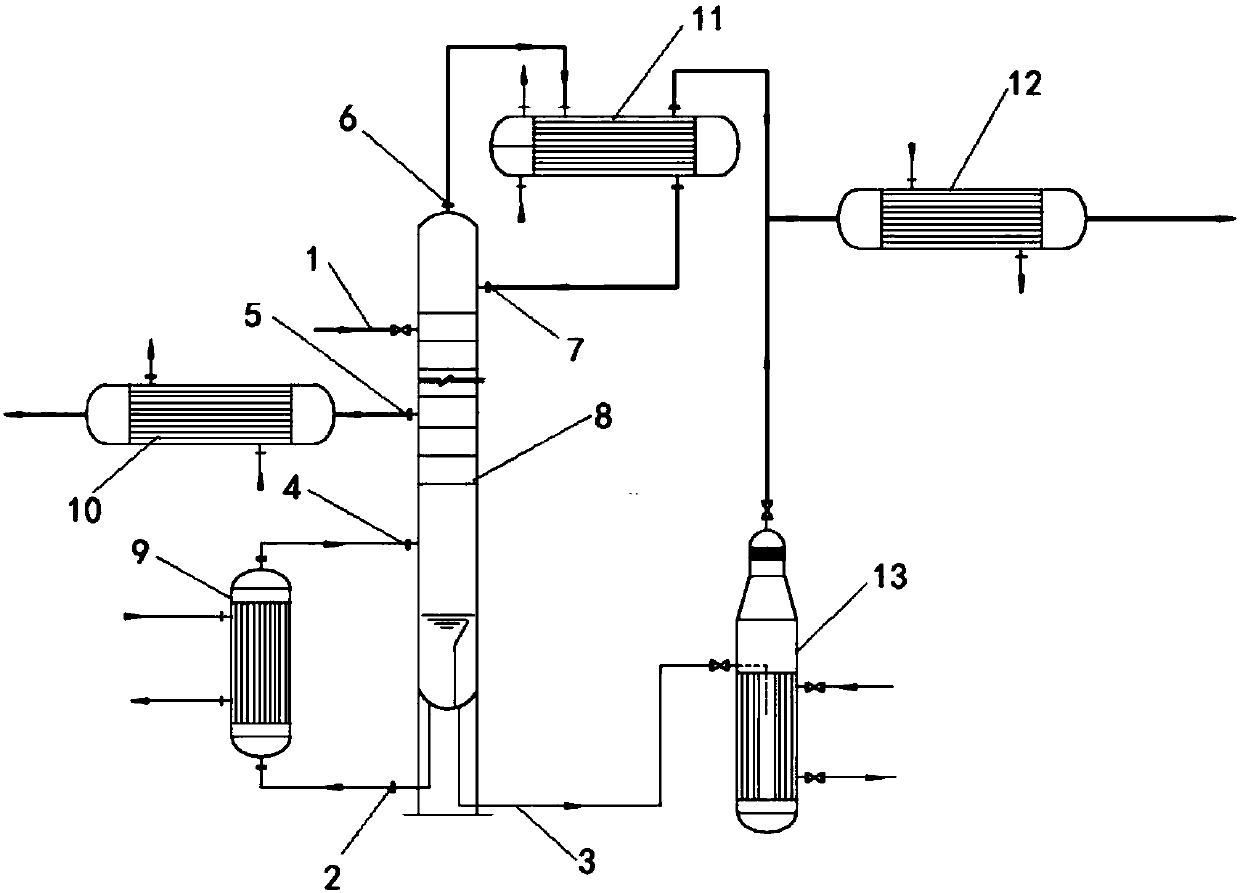

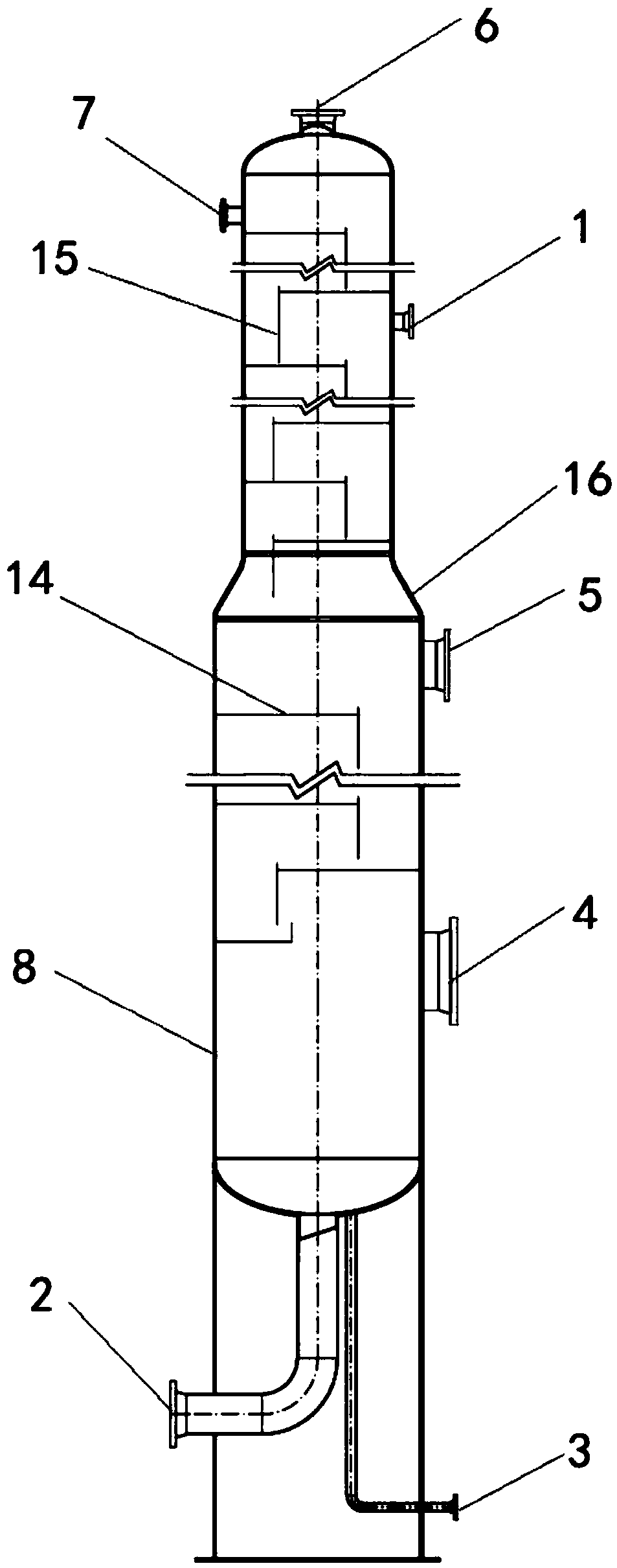

[0022] figure 1 Shows a chlorine gas refining production device constructed in accordance with the preferred embodiment of the present invention. Such as Figure 1-2 As shown, a chlorine gas purification production device is mainly composed of a chlorine gas rectification tower 8 and a bottom reboiler 9. The chlorine gas rectification tower 8 has multiple trays 14, and each tray 14 is provided with an overflow hole , The overflow holes on adjacent trays 14 are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com