Die-casting aluminum alloy cooker nanometer inorganic ceramic spraying treatment technology

A cast aluminum alloy, nano-inorganic technology, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc. Good antistatic properties, good UV resistance, the effect of increasing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The main steps of the embodiment of the present invention include:

[0023] (1) Pre-treatment, dehumidification and degreasing treatment of die-casting aluminum alloy cookware;

[0024] (2) Paint spraying, the spraying environment temperature is 20°C, the humidity is 70% RH, the spraying method is air spraying, the spray gun diameter is 1.0㎜, and the air pressure is 5-6 Kgf / cm2;

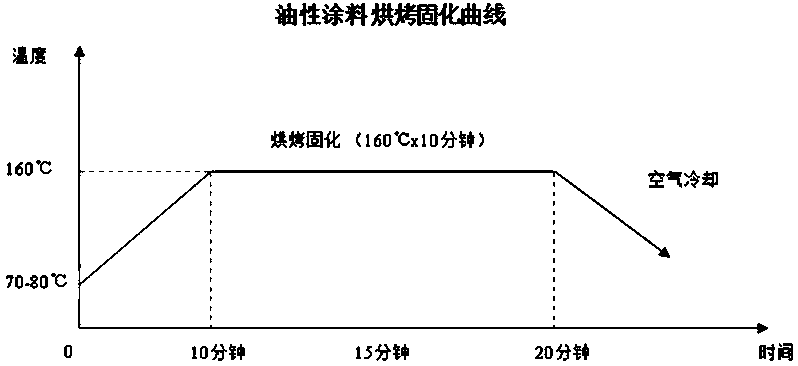

[0025] (3) curing, such as figure 2 As shown, the initial temperature is 60°C, gradually increase the temperature, and reach 160°C after 10 minutes, then keep baking at 160°C for 10 minutes, and finally cool down.

[0026] Before painting, use a 300-mesh or higher mesh filter to avoid particles in the paint film.

[0027] The thickness of the paint film is controlled within 15 μm, and the paint film is easy to crack if it exceeds this thickness.

[0028] During the processing, the surface of the substrate must be kept clean without any dust, oil, etc.

[0029] Step (2) After spraying the ...

Embodiment 2

[0031] The main steps of the embodiment of the present invention include:

[0032] (1) Pre-treatment, dehumidification and degreasing treatment of die-casting aluminum alloy cookware;

[0033] (2) Paint spraying, the spraying environment temperature is 25°C, the humidity is 70% RH, the spraying method is air spraying, the spray gun diameter is 1.0㎜, and the air pressure is 5-6 Kgf / cm2;

[0034] (3) curing, such as figure 2 As shown, the initial temperature is 60°C, gradually increase the temperature, and reach 160°C after 10 minutes, then keep baking at 160°C for 10 minutes, and finally cool down.

[0035] Before painting, use a 300-mesh or higher mesh filter to avoid particles in the paint film.

[0036] The thickness of the paint film is controlled within 15 μm, and the paint film is easy to crack if it exceeds this thickness.

[0037] During the processing, the surface of the substrate must be kept clean without any dust, oil, etc.

[0038] Step (2) After spraying the ...

Embodiment 3

[0040] The main steps of the embodiment of the present invention include:

[0041] (1) Pre-treatment, dehumidification and degreasing treatment of die-casting aluminum alloy cookware;

[0042] (2) Paint spraying, the spraying environment temperature is 20°C, the humidity is 70% RH, the spraying method is air spraying, the spray gun diameter is 1.2mm, and the air pressure is 5-6 Kgf / cm2;

[0043] (3) curing, such as figure 2 As shown, the initial temperature is 60°C, gradually increase the temperature, and reach 160°C after 10 minutes, then keep baking at 160°C for 10 minutes, and finally cool down.

[0044] Before painting, use a 300-mesh or higher mesh filter to avoid particles in the paint film.

[0045] The thickness of the paint film is controlled within 15 μm, and the paint film is easy to crack if it exceeds this thickness.

[0046] During the processing, the surface of the substrate must be kept clean without any dust, oil, etc.

[0047] Step (2) After spraying the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com