Production method of alkaline silica

A production method and white carbon black technology, applied in the direction of silica, silicon oxide, etc., can solve problems such as unfavorable processing, large specific surface area, and easy heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

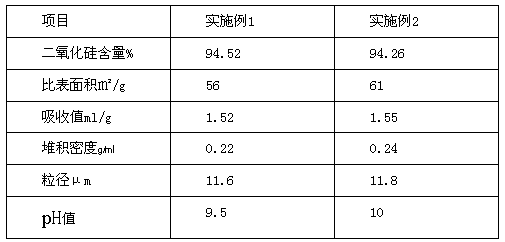

Embodiment 1

[0018] The specific operation steps of the production method of alkaline white carbon black are as follows:

[0019] 1. Refined water glass

[0020] Take 40m³ of water glass dissolved by steam, configure it into water glass with a specific gravity of 1.080-1.085g / cm³, filter it through a plate and frame, and take the clear liquid for later use.

[0021] 2. Synthesis of silica

[0022] Add 11m³ of base material into a 55m³ reactor, add sodium sulfate of the same quality at the same time, pass in steam to raise the temperature, start stirring when the temperature rises to 50 degrees, continue to heat up, start adding sulfuric acid dropwise when the temperature reaches 87 degrees, sulfuric acid per hour Add 0.15m³ dropwise, react until the pH value is between 10-11, start the second stage reaction, add water glass and sulfuric acid dropwise at the same time, add 19m³ of water glass dropwise per hour, add 0.42m³ of sulfuric acid dropwise per hour, and react until the pH value is ...

Embodiment 2

[0030] The specific operation steps of the production method of alkaline white carbon black are as follows:

[0031] 1. Refined water glass

[0032] Take 50m³ of water glass dissolved by steam, configure it into water glass with a specific gravity of 1.085-1.090g / cm³, filter it through a plate and frame, and take the clear liquid for later use.

[0033] 2. Synthesis of silica

[0034] Add 13m³ of base material into a 55m³ reactor, add sodium sulfate of the same quality at the same time, pass in steam to raise the temperature, start stirring when the temperature rises to 45°C, continue to heat up, start adding sulfuric acid dropwise when the temperature reaches 88°C, sulfuric acid per hour Add 0.16m³ dropwise, react until the pH value is between 10-11, start the second stage reaction, add water glass and sulfuric acid dropwise at the same time, add 17m³ of water glass dropwise per hour, add 0.37m³ of sulfuric acid dropwise per hour, and react until the pH value is 10 Stop dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com