Evaporator for salt-containing organic waste water of high concentration

A technology for high-concentration salt-containing, organic wastewater, applied in water pollutants, water/sewage treatment, chemical instruments and methods, etc. Low energy consumption and other problems, to achieve the effect of smooth flow channel, strong wear resistance and corrosion resistance, and reduce abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

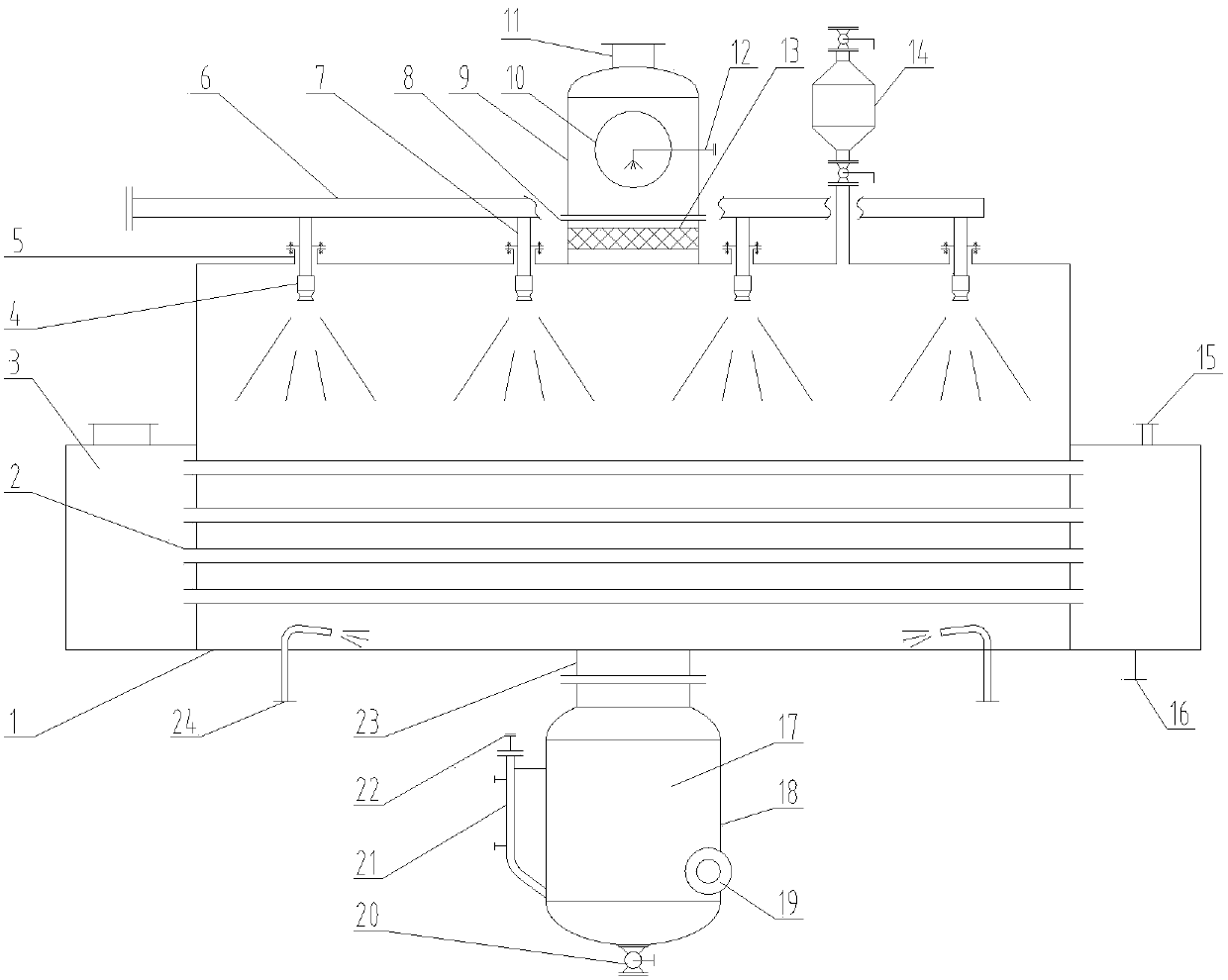

[0035] The specific embodiment of the present invention is as figure 1 As shown, an evaporator for high-concentration salt-containing organic wastewater according to the present invention includes an evaporation chamber, a spray pipeline 6 , a steam buffer tank 9 , a hot well 17 and a sand filling tank 14 .

[0036] The evaporation chamber includes a heat exchange tube bundle, an evaporation chamber cylinder 1, a foam removal device, a steam pipe box 3, and a purge pipeline 24; The chamber body 1 is a cylindrical body arranged horizontally, with tube plates at both ends, and is connected to the steam pipe boxes 3 at both ends through flanges; the demister device is composed of a demister 13 and its related accessories, installed in the evaporator The steam outlet position on the upper part of the cylinder body 1 can eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com