Mixed C4 utilizing method and device

A technology for mixing C4 and mixtures, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve problems such as difficult separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0017] According to a preferred embodiment of the present invention, the composition content of the mixed C4 may be 5-10% by weight of 1-butene, 5-15% by weight of isobutene, 10-20% by weight of 1,3-butadiene, 1 , 5-15% by weight of 2-butadiene, 0.5-5% by weight of n-butane, 0.5-2% by weight of isobutane, 20-40% by weight of cis-2-butene, 2-10% by weight of trans-2-butene %, vinyl acetylene 5 to 20% by weight.

[0018] According to another preferred embodiment of the present invention, the composition content of the mixed C4 may be 0.1-2% by weight of 1-butene, 10-30% by weight of isobutene, 0.01-0.1% by weight of 1,3-butadiene, 0.5 to 5% by weight of n-butane, 30 to 40% by weight of isobutane, 20 to 40% by weight of cis-2-butene, and 5 to 20% by weight of trans-2-butene.

[0019] According to another preferred embodiment of the present invention, the composition content of the mixed C4 may be 5-15% by weight of 1-butene, 0.5-3% by weight of isobutene, 20-30% by weight of n-b...

Embodiment 1

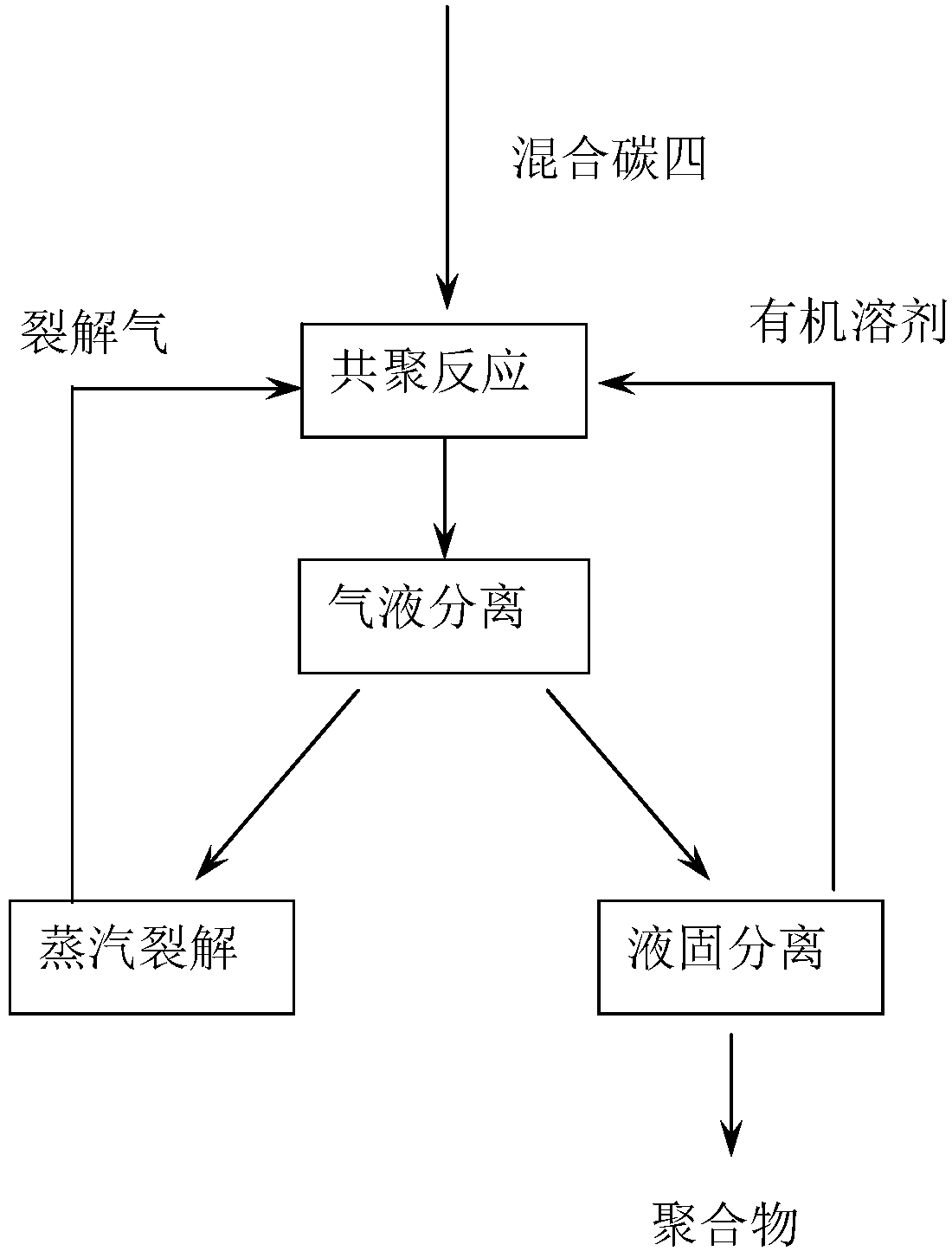

[0075] This example illustrates the method for utilization of mixed C4 of the present invention.

[0076] The mixed C4A of 14kg is passed into the reaction kettle of 200L that fills the organic reaction solution of 20kg maleic anhydride, 2.4kg azobisisobutyronitrile and 100L isoamyl acetate to carry out free radical copolymerization reaction, and copolymerization reaction pressure is 0.9MPa, the copolymerization reaction temperature is 70°C, and the copolymerization reaction time is 6h;

[0077] Pass the copolymerization reaction product into the flash separator for gas-liquid separation at 25°C and 0MPa. The obtained liquid-solid mixture continues to be separated in the centrifuge at 4000rpm and centrifuged for 20min to obtain a solid copolymer. Powder and liquid are returned to the reactor.

[0078] The gas phase product obtained by flash separation is passed into the cracking furnace for steam cracking reaction at 800°C, and the cracked gas obtained is returned to the abov...

Embodiment 2

[0083] This example illustrates the method for utilization of mixed C4 of the present invention.

[0084] The mixed carbon four B of 13.5kg is passed into the reaction kettle of 200L that fills the organic reaction solution of 20kg maleic anhydride, 4kg dibenzoyl peroxide and 100L isoamyl acetate to carry out radical copolymerization reaction, and copolymerization reaction pressure is 1MP, the copolymerization reaction temperature is 80°C, and the copolymerization reaction time is 6h;

[0085] Pass the copolymerization reaction product into the flash separator for gas-liquid separation at 30°C and 0MPa, and continue to separate the liquid-solid mixture in the centrifuge at 4000rpm for 20 minutes to obtain solid copolymer particles Powder and liquid are returned to the reactor.

[0086] The gas phase product obtained by flash separation is passed into the cracking furnace, and the steam cracking reaction is carried out at 820°C, and the cracked gas obtained is returned to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com