Environment-friendly type inner tire and production method thereof

An environment-friendly inner tube technology, applied in coating, plastic recycling, recycling technology, etc., can solve the problem of polycyclic aromatic hydrocarbons exceeding the standard, and achieve the effects of reducing the content of polycyclic aromatic hydrocarbons, reducing pollution, and being easy to crush

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

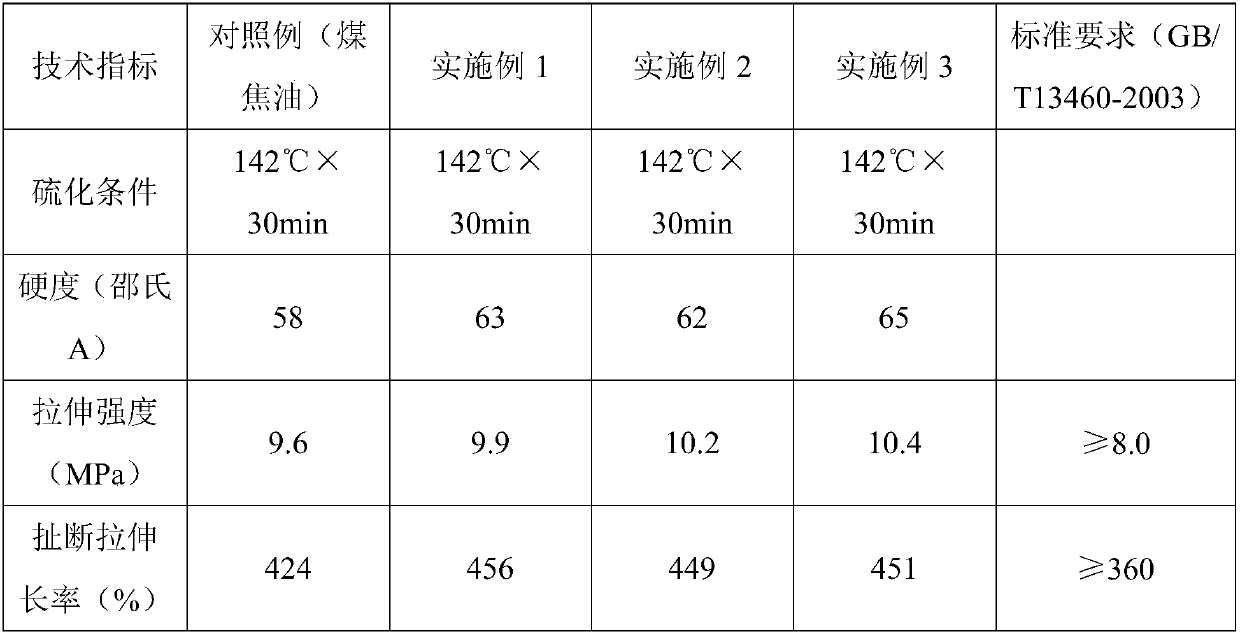

Examples

Embodiment 1

[0034] A kind of regenerated butyl rubber, comprising: rubber powder 1000g, rapeseed oil 15g, cottonseed oil 15g, rubber seed oil 20g, stearic acid 1g.

[0035] The particle size of the rubber powder in this embodiment is 0-0.2mm.

[0036] Above-mentioned regenerated butyl rubber is prepared by following steps:

[0037] S1. Rinse the waste butyl inner tube and put it into the soaking tank, heat it to 110°C, soak in the soaking solution for 2 hours, so that the butyl inner tube decomposes and releases harmful substances, and at the same time, use a biochemical absorption tower to purify the harmful gas;

[0038] S2. Crush the above-mentioned treated butyl inner tube into rubber powder after ultra-low temperature freezing, and select a 5-mesh sieve to sieve the crushed inner tube. The freezing temperature is -50 to -45°C;

[0039] S3, the weight batching of each component in the following table:

[0040] raw material

rubber powder

canola oil

cottonseed oil...

Embodiment 2

[0045] A kind of regenerated butyl rubber, comprising: rubber powder 1000g, rapeseed oil 20g, cottonseed oil 20g, rubber seed oil 30g, stearic acid 2g.

[0046] The particle size of the rubber powder in this embodiment is 0.1-0.3 mm.

[0047]Above-mentioned regenerated butyl rubber is prepared by following steps:

[0048] S1. Rinse the waste butyl inner tube and put it into the immersion pool, heat it to 100°C, soak in the soaking solution for 3 hours, decompose the butyl inner tube to release harmful substances, and purify the harmful gas with a biochemical absorption tower;

[0049] S2. The butyl inner tube treated above is crushed into rubber powder after ultra-low temperature freezing, and a 5-mesh screen is selected to sieve the crushed inner tube, and the freezing temperature is -30~-25°C;

[0050] S3, the weight batching of each component in the following table:

[0051] raw material

rubber powder

canola oil

...

Embodiment 3

[0056] A kind of regenerated butyl rubber, comprising: rubber powder 1000g, rapeseed oil 18g, cottonseed oil 18g, rubber seed oil 40g, stearic acid 3g.

[0057] The particle size of the rubber powder in this embodiment is 0.2-0.4 mm.

[0058] Above-mentioned regenerated butyl rubber is prepared by following steps:

[0059] S1. Rinse the waste butyl inner tube and put it into the soaking tank, heat it to 120°C, soak in the soaking solution for 1 hour, so that the butyl inner tube decomposes and releases harmful substances, and at the same time, use a biochemical absorption tower to purify the harmful gas;

[0060] S2. The above treated butyl inner tube is crushed into rubber powder after ultra-low temperature freezing, and a 6-mesh screen is selected to sieve the crushed inner tube, and the freezing temperature is -25 to -20°C;

[0061] S3, the weight batching of each component in the following table:

[0062] raw material

rubber powder

canola oil

cottons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com