High-efficiency flame-retardant PP composition special for LFT-D

A technology of LFT-D and composition, applied in the field of high-efficiency flame-retardant PP composition for LFT-D, can solve the problems of poor flame-retardant performance, low safety, smoke generation, etc., so as to achieve less influence on material mechanical properties and improve mechanical properties. performance, the effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

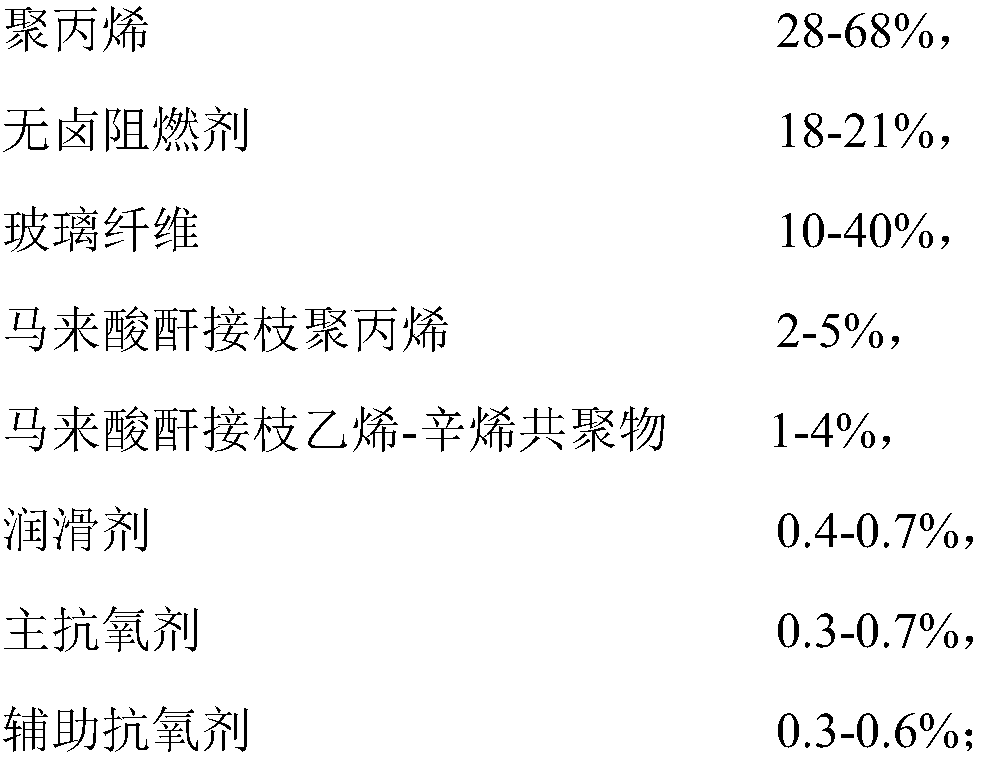

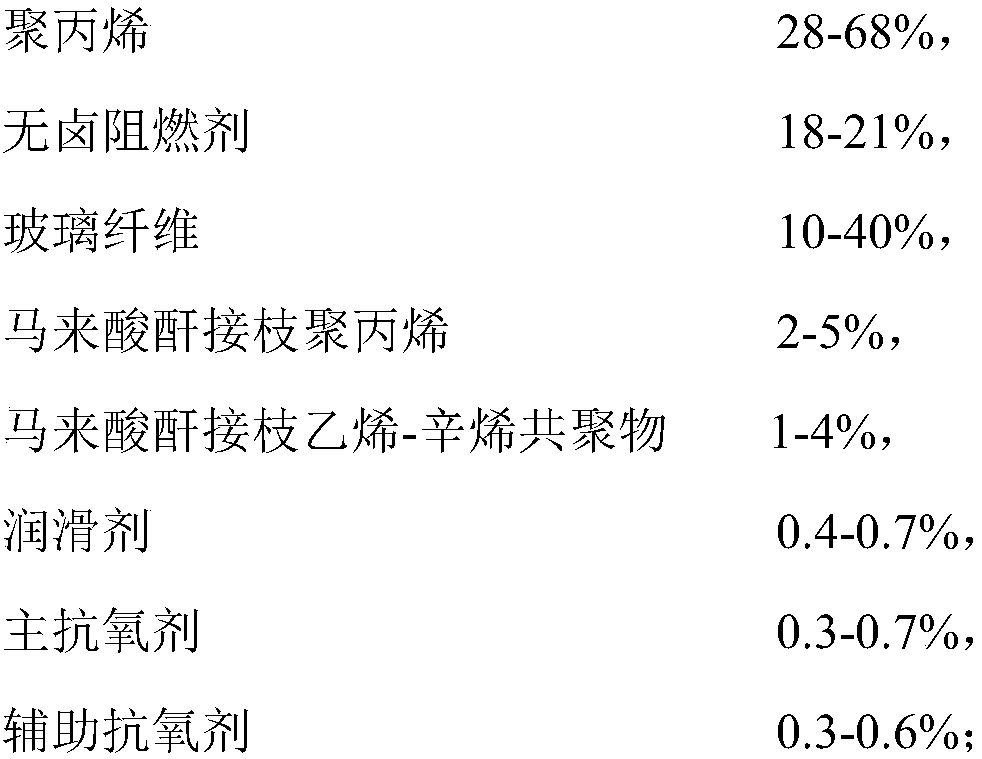

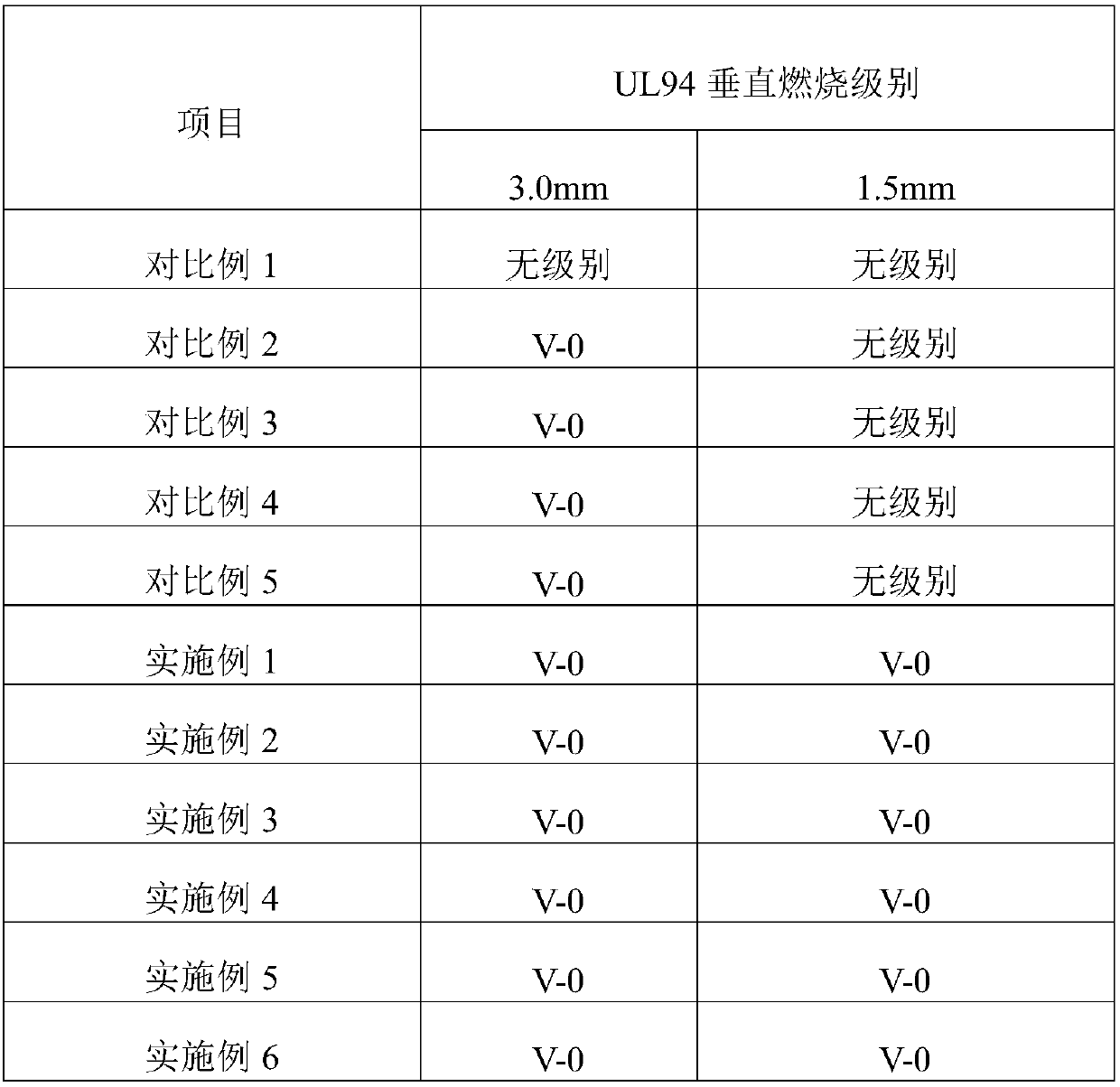

[0031] The high-efficiency flame-retardant PP composition dedicated to LFT-D in this embodiment is made of the following raw materials in mass percentage: 44.8% polypropylene, 18% halogen-free flame retardant, 30% glass fiber, 3% MAH-g-PP, MAH -g-POE 3%, lubricant EBS 0.6%, primary antioxidant 1010 0.3% and secondary antioxidant 168 0.3%.

[0032] The halogen-free flame retardant is surface treated with silane coupling agent KH-550. The preparation method of described fire retardant comprises the following steps:

[0033] 1) 30% piperazine pyrophosphate, 69% melamine pyrophosphate MPP, and 1% zinc oxide are mixed uniformly in a high-speed mixer according to the ratio (mass percentage) at room temperature;

[0034] 2) Mix the homogeneously mixed mixture in step 1) with 1% silane coupling agent KH-550, and heat-treat at 150°C for 2 hours with stirring; after cooling, a halogen-free flame retardant is obtained.

[0035] The preparation method of the high-efficiency flame-retard...

Embodiment 2

[0051] The high-efficiency flame-retardant PP composition dedicated to LFT-D in this embodiment is made of the following raw materials in mass percentage: 44.8% polypropylene, 18% halogen-free flame retardant, 30% glass fiber, 3% MAH-g-PP, MAH -g-POE 3%, lubricant EBS 0.6%, primary antioxidant 1010 0.3%, auxiliary antioxidant 168 0.3%.

[0052] The halogen-free flame retardant is surface treated with dimethyl silicone oil. The preparation method of described fire retardant comprises the following steps:

[0053] 1) Mix 63% piperazine pyrophosphate, 32% melamine pyrophosphate MPP, and 5% zinc oxide in a high-speed mixer in proportion (mass percentage) at room temperature;

[0054] 2) Mix the homogeneously mixed mixture in step 1) with 2% simethicone oil, and heat-treat at 120° C. for 2 hours; after cooling, the above-mentioned halogen-free flame retardant is obtained.

[0055] The preparation method of the high-efficiency flame-retardant PP composition for LFT-D is as follows...

Embodiment 3

[0058] The high-efficiency flame-retardant PP composition dedicated to LFT-D in this embodiment is made of the following raw materials in mass percentages: polypropylene 43.2%, halogen-free flame retardant 19.6%, glass fiber 30%, MAH-g-PP 4%, MAH -g-POE 2%, lubricant EBS 0.6%, primary antioxidant 1010 0.3% and secondary antioxidant 168 0.3%.

[0059] The halogen-free flame retardant is surface-treated with silane coupling agent KH-470. The preparation method of described fire retardant comprises the following steps:

[0060] 1) Mix 40% piperazine pyrophosphate, 55% melamine pyrophosphate MPP, and 5% zinc oxide in a high-speed mixer according to the ratio (mass ratio) at room temperature;

[0061] 2) Mix the homogeneously mixed mixture in step 1) with 0.5% silane coupling agent KH-470, and heat-treat at 180° C. for 2 hours; after cooling, the above-mentioned halogen-free flame retardant is obtained.

[0062] The preparation method of the high-efficiency flame-retardant PP com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com