Preparation method and application of fermented angelica extract with sweet aromas

An angelica extract, sweet and fragrant technology is applied in the field of preparation of fermented angelica extract to achieve the effects of improving extraction efficiency, expanding application economic value, and increasing richness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

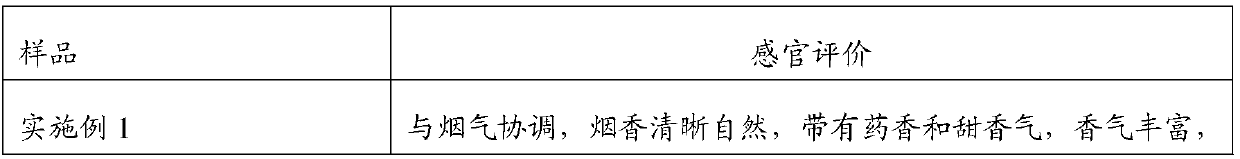

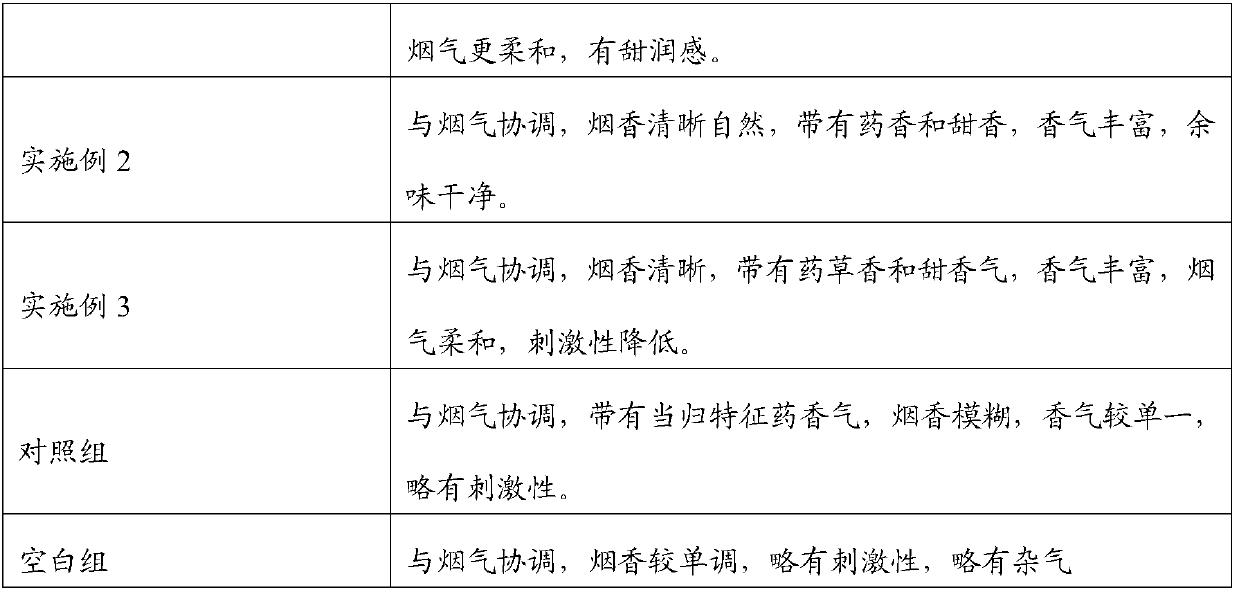

Examples

Embodiment 1

[0026] A preparation method with a sweet and fragrant fermented Angelica sinensis extract, comprising the steps of:

[0027] (1) Low-temperature ultrafine pulverization and pressurized cell wall breaking: put the root of Angelica sinensis into a liquid nitrogen frozen ultrafine pulverizer at 0°C and pulverize into ultrafine powder with a mesh number of 300, and mix the ultrafine powder and water in a mass ratio of 1: 10 Mix evenly, pour into a high-pressure extraction tank, pressurize to 11MPa, 10min, release the pressure to normal pressure;

[0028] (2) Biotransformation of compound biological preparations: add malic acid (food grade, accounting for 0.1% of the quality of Angelica sinensis raw material) in the extraction tank, adjust pH 6.5, add compound biological preparations (548-D fusion Lactobacillus weissnerii, β-glucoside Enzymes, acid protease, cellulase, and pectinase are all food grade, accounting for 0.1% of the mass of angelica raw materials, the mass ratio is 1:0...

Embodiment 2

[0033] A preparation method with a sweet and fragrant fermented Angelica sinensis extract, comprising the steps of:

[0034](1) Low-temperature ultrafine pulverization and pressurized cell wall breaking: Put the root of Angelica sinensis into a liquid nitrogen freezing ultrafine pulverizer at -2°C to pulverize into ultrafine powder with a mesh number of 320 mesh, and mix the ultrafine powder and water according to the mass ratio 1:20 mix evenly, pour into the high-pressure extraction tank, pressurize to 20MPa, 7min, release the pressure to normal pressure;

[0035] (2) Biotransformation of compound biological preparations: add malic acid (food grade, accounting for 0.2% of the quality of Angelica sinensis raw material) in the extraction tank, adjust pH 6.0, add compound biological preparations (548-D fusion Lactobacillus weissnerii, β-glucoside Enzymes, acid protease, cellulase, and pectinase are all food grade, accounting for 0.2% of the mass of angelica raw materials, the ma...

Embodiment 3

[0040] A preparation method with a sweet and fragrant fermented Angelica sinensis extract, comprising the steps of:

[0041] (1) Low-temperature ultrafine pulverization and pressurized cell wall breaking: Put the root of Angelica sinensis into a liquid nitrogen frozen ultrafine pulverizer at -4°C to pulverize into ultrafine powder with a mesh number of 280 mesh, and mix the ultrafine powder and water according to the mass ratio 1:40 mix evenly, pour into the high-pressure extraction tank, pressurize to 30MPa, 5min, release the pressure to normal pressure;

[0042] (2) Biotransformation of compound biological preparations: add malic acid (food grade, accounting for 0.5% of the quality of Angelica sinensis raw material) in the extraction tank, adjust pH 5.0, add compound biological preparations (548-D fusion Lactobacillus weissnerii, β-glucoside Enzyme, acid protease, cellulase, and pectinase, which account for 0.3% of the quality of Angelica raw materials, are all food grade, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com