Waste heat stairstep recycling system and method for electrolytic aluminum plant

A cascade recovery and waste heat technology, applied in heat exchangers, heat exchange equipment, heat exchanger types, etc., can solve the problems of waste of low-grade heat energy, achieve the effects of saving electric energy, good heat recovery effect, and preventing water evaporation and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

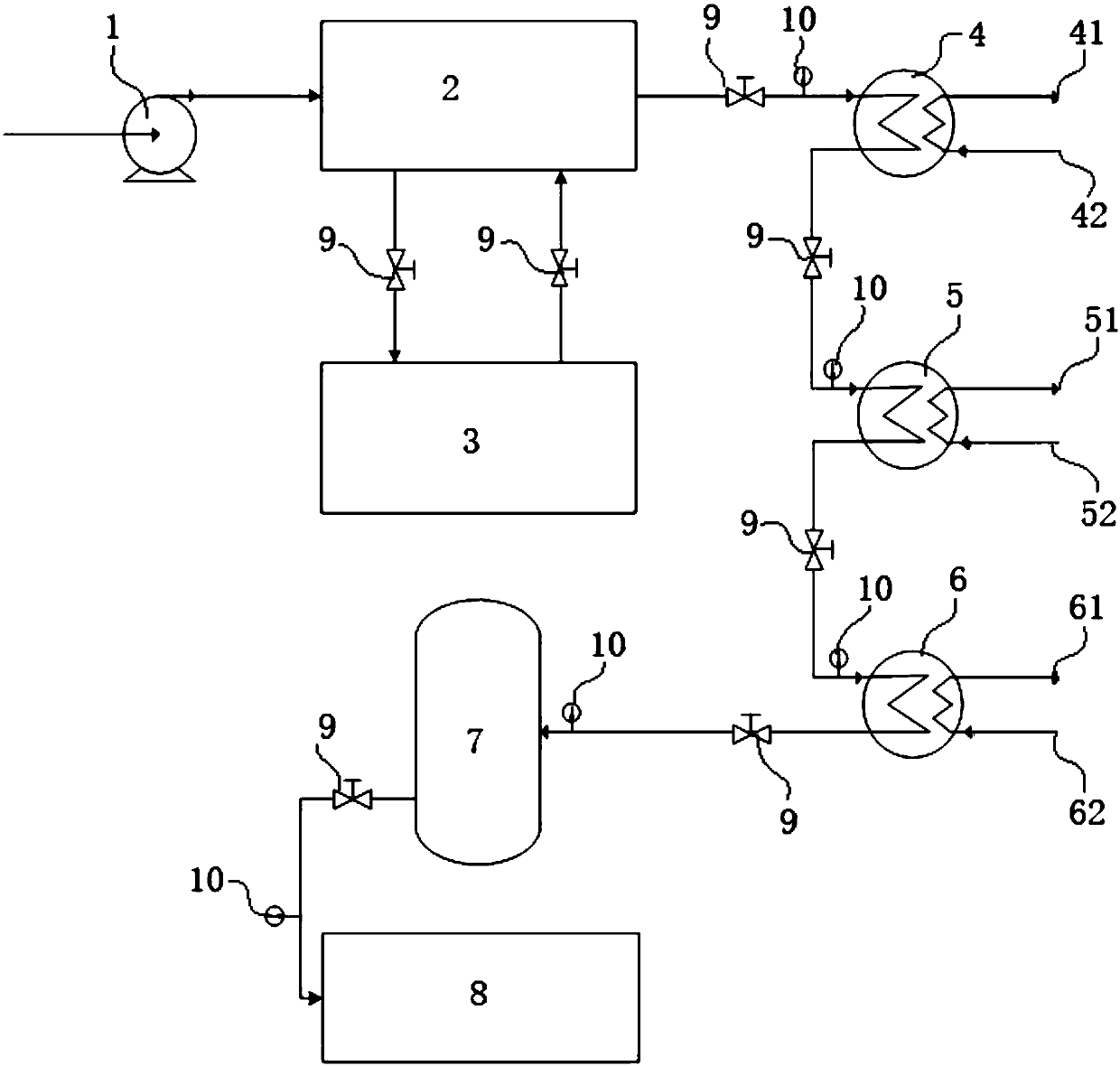

[0023] see figure 1 , a waste heat cascade recovery system of an electrolytic aluminum plant in the diagram is the preferred solution of the present invention, specifically including a centrifugal pump 1, a water source heat pump 2, an air compressor 3, a high-temperature compressed air heat exchanger 4, and a high-temperature oil heat exchanger 5 , High-temperature flue gas heat exchanger 6, water storage tank 7, etc.

[0024] Specifically, centrifugal pump 1, water source heat pump 2, high-temperature compressed air heat exchanger 4, high-temperature oil heat exchanger 5, high-temperature flue gas heat exchanger 6, and water storage tank 7 are sequentially connected in series through pipelines, and centrifugal pump 1 is connected to normal temperature tap water 11 , Input normal temperature tap water at about 20°C to the waste heat cascade recovery system. The high-temperature compressed air heat exchanger 4, the high-temperature oil heat exchanger 5, and the high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com