Surface roughness measurement method based on support vector regression machine

A support vector regression and surface roughness technology, which is applied in the field of surface roughness measurement, can solve problems such as the inability to obtain roughness values, and achieve the effects of complete functions, improved precision, and high-performance processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further specifically described below in conjunction with the accompanying drawings.

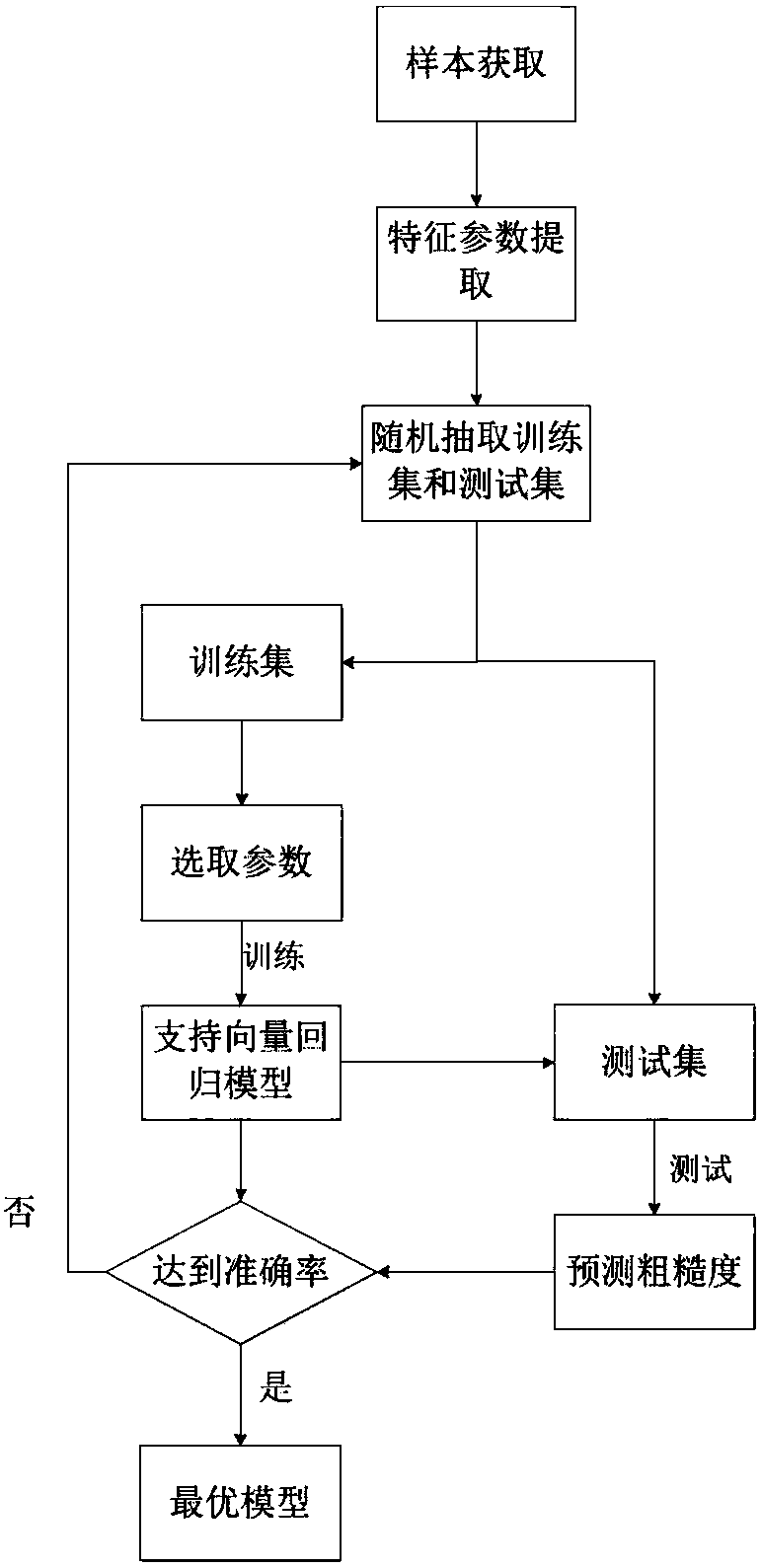

[0024] Such as figure 1 As shown, a method for measuring surface roughness based on a support vector regression machine disclosed in an embodiment of the present invention mainly includes the following steps:

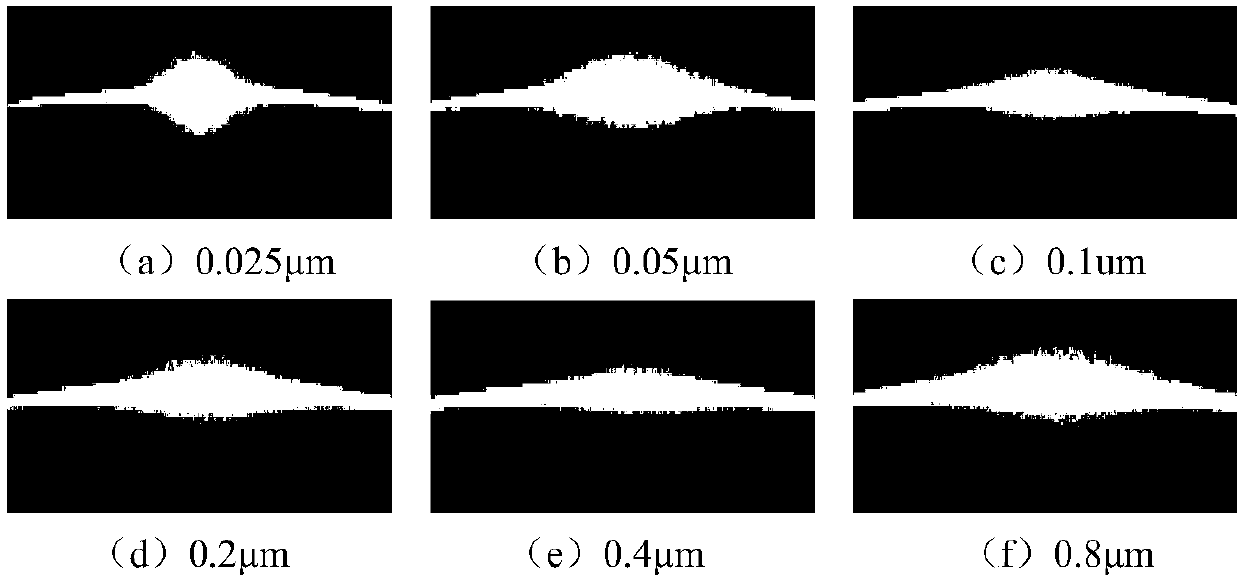

[0025] (1) The collimated laser beam is slanted onto the surface of the workpiece, and the camera is used to capture the spatial distribution images of reflected and scattered light carrying surface roughness information to obtain the scattered images of standard samples with different roughness. In this step, the spatial light scattering distribution images corresponding to different roughness values can be obtained through the built measurement system. The measurement system in this step includes a laser, a ground glass screen and a camera. A semiconductor collimated laser with a wavelength of 632.8nm is selected as a light source, and a collim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com