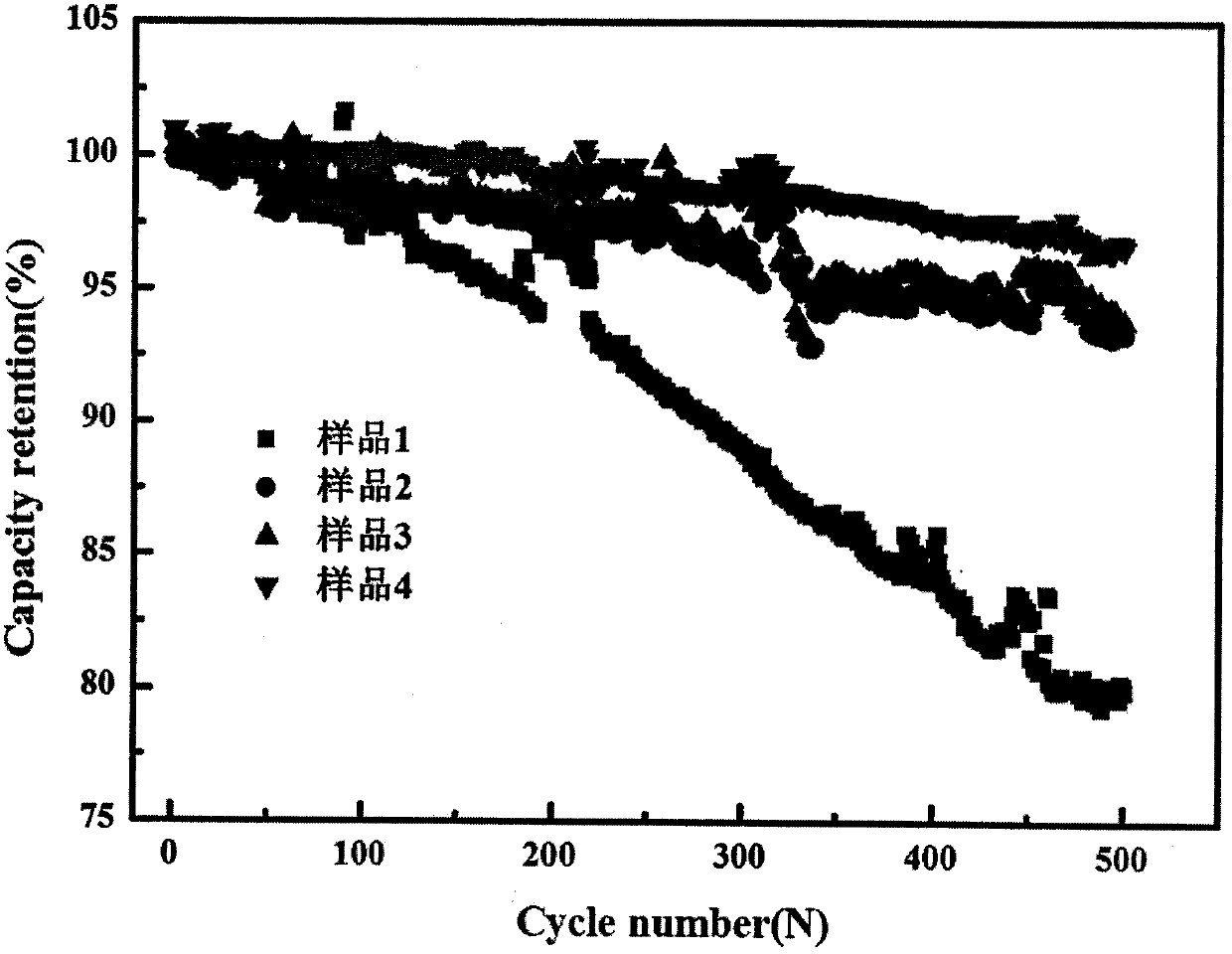

High-voltage electrolyte for lithium-ion battery and application thereof

A power battery and high-voltage technology, which is applied in the field of chemical power sources, can solve the problems of battery internal resistance increase and battery cycle performance decline, and achieve the effects of reducing thickness expansion rate, preventing metal ion dissolution, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Electrode Preparation

[0027] The binder polyvinylidene fluoride (PVDF) is uniformly dispersed in N-methylpyrrolidone (NMP) solution, and configured as a 10% (mass fraction) solution. According to the active material m(LiCoO 2 ):m(SP):m(PVDF)=8:1:1 Accurately weigh the active substance and SP, grind for 30 minutes, pour into the weighed PVDF solution, and add a certain amount of NMP to adjust the viscosity. After the slurry is prepared, it is evenly coated on an aluminum foil, dried in vacuum at 80°C for 10 h, pressed at 10 MPa, and weighed for future use.

[0028] 2. Battery assembly

[0029] The metal lithium sheet is used as the counter electrode, the diaphragm is Celgard2400, and the electrolyte lithium salt is 1.0-1.2mol / L LiPF 6 , the non-aqueous organic solvent was EC:EMC:DMC (1:1:1v / v), the electrolyte additives were 0.5-1%PST and 0.5-1%LiDFP, and the CR2016 battery was assembled in a Braun glove box in Germany.

[0030] The electrolyte lithium salt is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com