Method for improving high-shale-content copper oxide ore dressing indicators

A technology of copper oxide ore and mud, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of reducing the type and amount of flotation reagents, and achieve easy industrial implementation, increase selectivity and capture Performance, the effect of simple beneficiation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

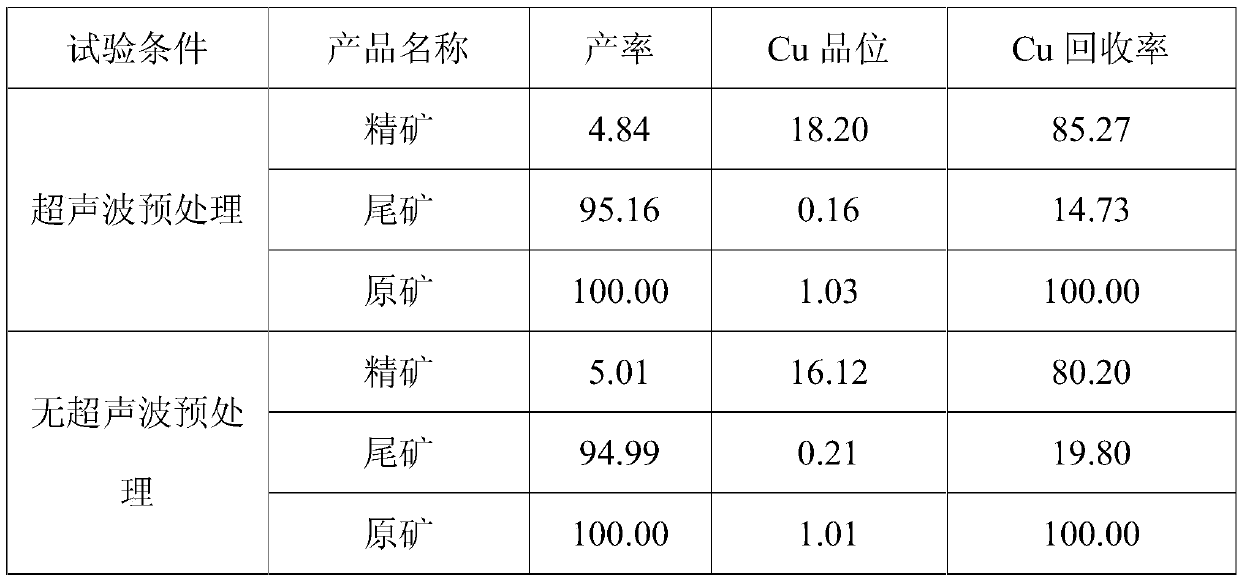

[0021] In this embodiment, the raw ore is a certain copper oxide 1, which is a high argillaceous copper oxide ore with a grade of about 1.03%. Copper is recovered by pretreatment with ultrasonic technology.

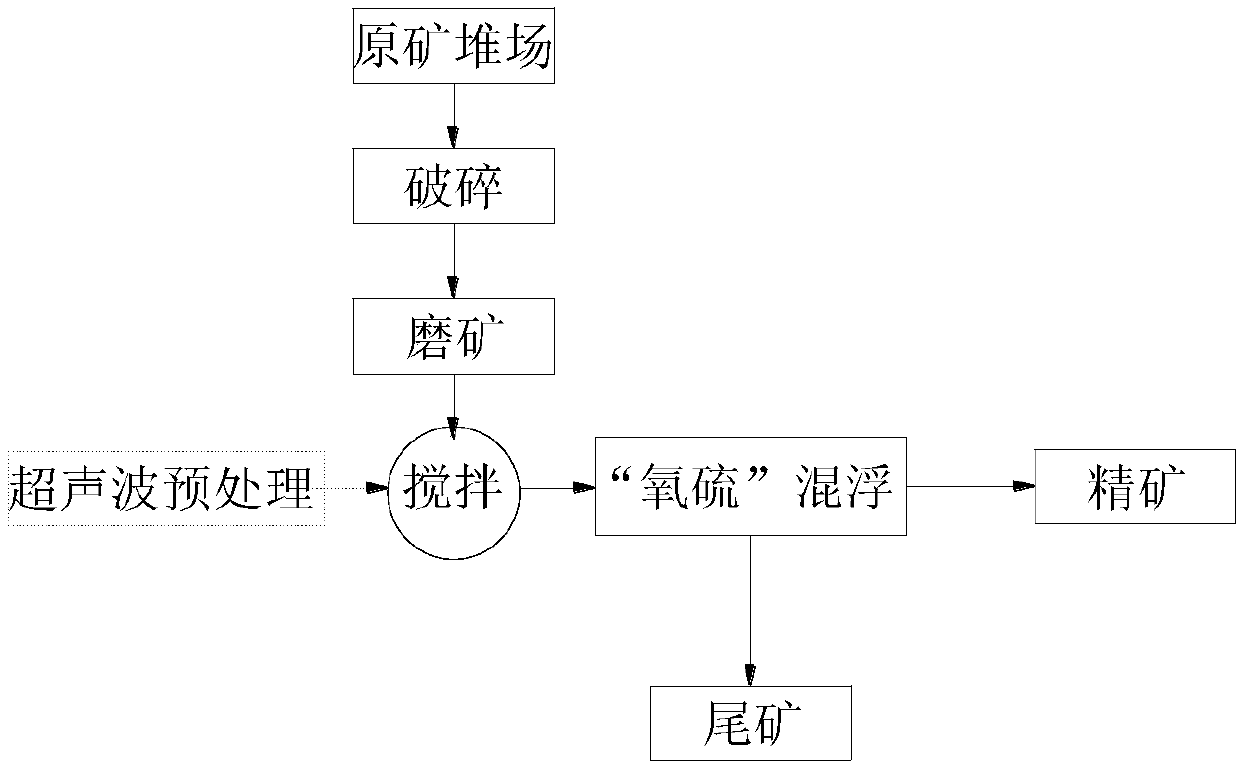

[0022] The present invention adopts the beneficiation technological process of ultrasonic technology pretreatment method:

[0023] (1) Grinding, the raw ore is crushed and sent to the mill for grinding until the fineness is -0.074mm and the content accounts for about 88%, and the pulp is adjusted to the pulp concentration of 20%;

[0024] (2) Ultrasonic pretreatment, the overflow of the ore pulp obtained in S1 is sent into an ultrasonic stirring tank for ultrasonic pretreatment, the ultrasonic pretreatment time is 8min, the ultrasonic frequency is 28kHz, and the power is 900W to obtain the pretreated ore pulp;

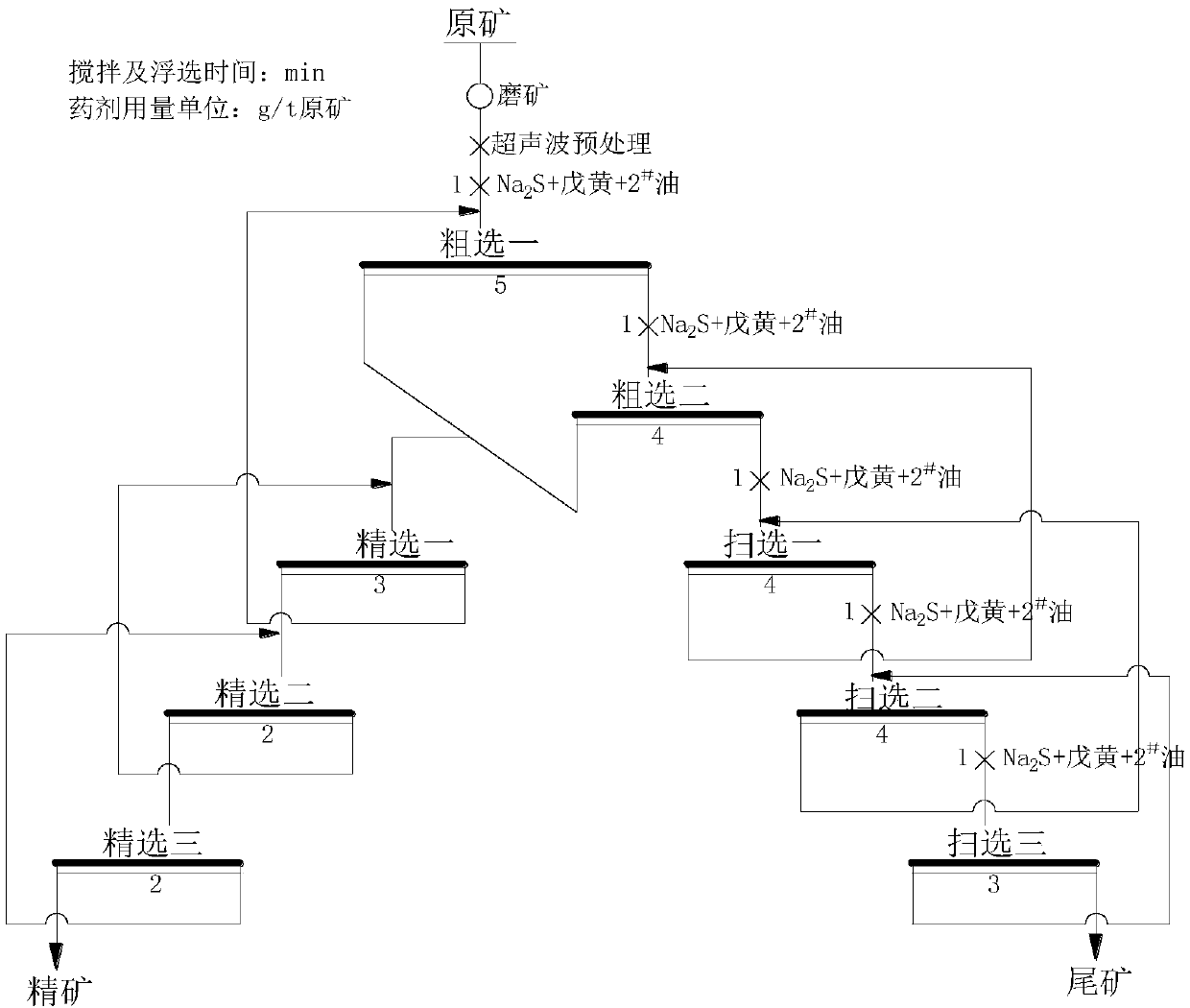

[0025] (3) Flotation, the pretreated ore pulp obtained in S2 is sent into the flotation cell, and the ore dressing process of "twice roughing, three times sweepi...

Embodiment 2

[0034] In this embodiment, the raw ore is a certain copper oxide 2, which is high muddy, highly oxidized, and highly alkaline gangue-containing ore. The recyclable valuable element in the raw ore is copper, and the grade is about 1%. Coarse three-sweeping and two-finishing process flow, using the method provided by the present invention and the method without ultrasonic technology pretreatment to recover copper.

[0035] The present invention adopts the beneficiation technological process of ultrasonic technology pretreatment method:

[0036] (1) Grinding, the raw ore is crushed and sent to the mill for grinding, the content of ore grinding to a fineness of -0.074mm accounts for about 85%, and the pulp is adjusted to a pulp concentration of 22%;

[0037] (2) Ultrasonic pretreatment, the described ore pulp overflow that obtains in (1) is sent into ultrasonic agitation tank, carries out ultrasonic pretreatment, and ultrasonic pretreatment time is 5min, and ultrasonic frequency i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com