Electroplating nickel-cobalt-manganese alloy coating on copper plate of continuous casting crystallizer and its preparation process

A technology for continuous casting of crystallizer and crystallizer copper plate, applied in electrodes, electrolysis components, electrolysis process, etc., can solve problems such as increased production cost, and achieve the effect of reducing the number of grains, low porosity, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

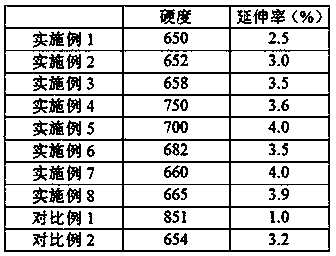

Examples

Embodiment 1

[0029] A nickel-cobalt-manganese alloy coating layer electroplated on a continuous casting crystallizer copper plate, comprising a crystallizer copper plate substrate, the surface of the crystallizer copper plate substrate is coated with a Ni-Co-Mn alloy layer, and the Ni-Co-Mn alloy layer contains a coating quality 95% Ni, 4% Co and 1% Mn, the thickness is 0.2mm.

[0030] The preparation technology of electroplating nickel-cobalt-manganese alloy coating on copper plate of continuous casting crystallizer comprises the following steps:

[0031] (1) Pre-treatment of substrate electroplating: degreasing and degreasing, mechanical sandblasting, electrolytic degreasing and degreasing of the copper plate substrate of the continuous casting crystallizer in sequence, fixed electroplating auxiliary tooling, and activated by hydrochloric acid spraying;

[0032] (2) Preparation of electroplating solution: prepare a composite electroplating solution containing nickel-cobalt-manganese allo...

Embodiment 2

[0038] A nickel-cobalt-manganese alloy coating layer electroplated on a continuous casting crystallizer copper plate, comprising a crystallizer copper plate substrate, the surface of the crystallizer copper plate substrate is coated with a Ni-Co-Mn alloy layer, and the Ni-Co-Mn alloy layer contains a coating quality 95.6% Ni, 3.5% Co and 0.9% Mn, with a thickness of 0.5mm.

[0039] The preparation technology of electroplating nickel-cobalt-manganese alloy coating on copper plate of continuous casting crystallizer comprises the following steps:

[0040] (1) Pre-treatment of substrate electroplating: degreasing and degreasing, mechanical sandblasting, electrolytic degreasing and degreasing of the copper plate substrate of the continuous casting crystallizer in sequence, fixed electroplating auxiliary tooling, and activated by hydrochloric acid spraying;

[0041] (2) Preparation of electroplating solution: prepare a composite electroplating solution containing nickel-cobalt-manga...

Embodiment 3

[0047] A nickel-cobalt-manganese alloy coating layer electroplated on a continuous casting crystallizer copper plate, comprising a crystallizer copper plate substrate, the surface of the crystallizer copper plate substrate is coated with a Ni-Co-Mn alloy layer, and the Ni-Co-Mn alloy layer contains a coating quality 96% Ni, 3.5% Co and 0.5% Mn, the thickness is 1mm.

[0048] The preparation technology of electroplating nickel-cobalt-manganese alloy coating on copper plate of continuous casting crystallizer comprises the following steps:

[0049] (1) Pre-treatment of substrate electroplating: degreasing and degreasing, mechanical sandblasting, electrolytic degreasing and degreasing of the copper plate substrate of the continuous casting crystallizer in sequence, fixed electroplating auxiliary tooling, and activated by hydrochloric acid spraying;

[0050] (2) Preparation of electroplating solution: prepare a composite electroplating solution containing nickel-cobalt-manganese al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com