Monodisperse high-purity lead iodide preparation method

A lead iodide, monodisperse technology, applied in the direction of lead halide, etc., can solve the problems of product quality failure, product phase impurity, etc., and achieve the effect of stable and reliable quality, high purity, and easy scale-up preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

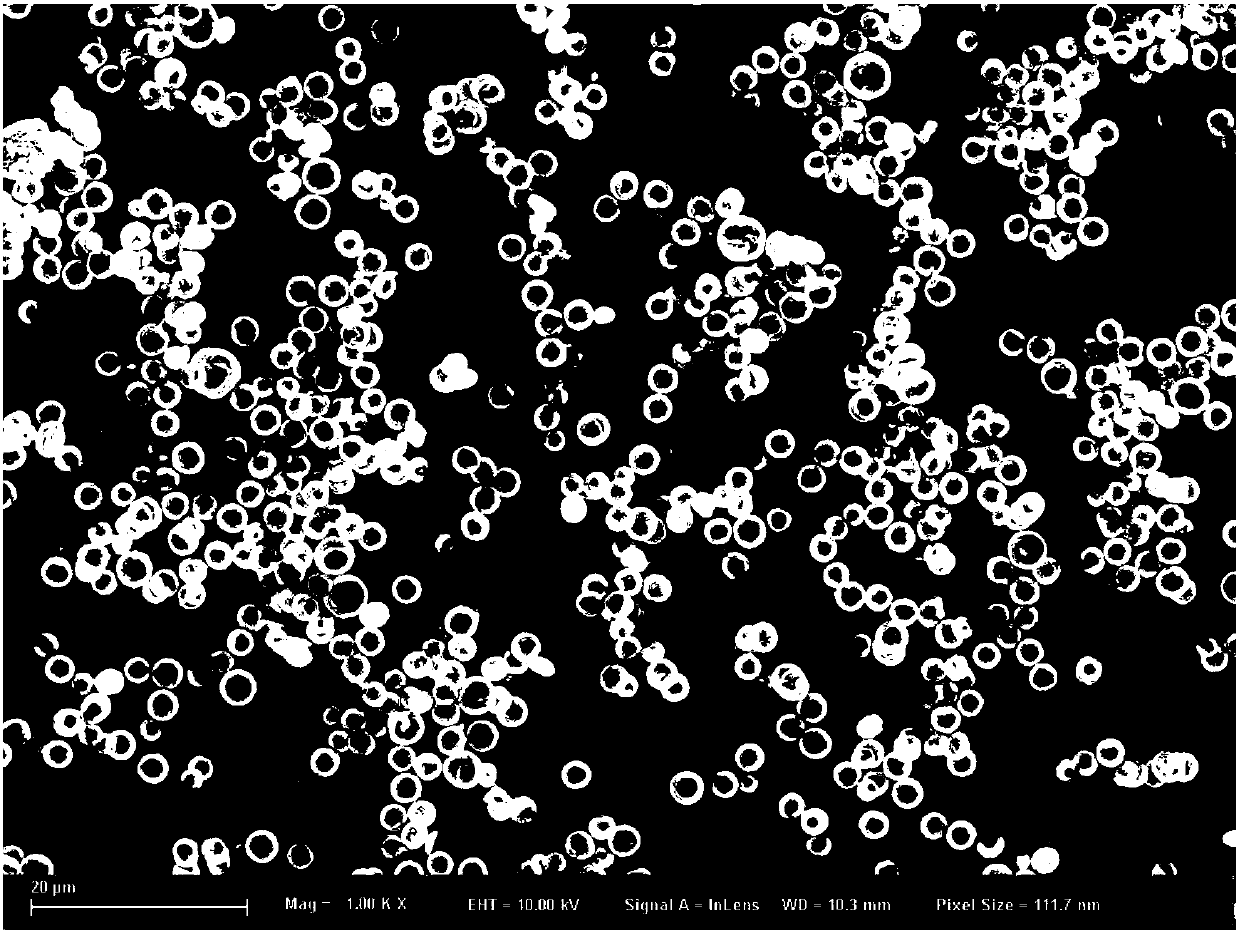

[0027] Prepare 10 liters of 0.1M lead nitrate solution and 10 liters of 0.11M potassium iodide solution, pre-adjust their respective pH to 3, and then add them dropwise to 10 liters of aqueous solution at a rate of 0.5 liters per minute (keep stirring , whose pH value is pre-adjusted to 3, and pre-prepared with 0.1% polyvinylpyrrolidone K-30 and 0.5% sodium citrate), after the dropwise addition, continue to stir and age for 10 hours, filter, use deionized Washed three times with water and dried at 80°C. The monodisperse lead iodide powder product can be obtained, and its typical morphology features are as follows figure 1 As shown, it is a flat, disc-shaped shape with a diameter of about 3 microns.

Embodiment 2

[0029] Prepare 10 liters of 0.25M lead chloride solution and 10 liters of 0.27M sodium iodide solution, pre-adjust their respective pH to 3.5, and then add them dropwise to 20 liters of aqueous solution at a rate of 1 liter / minute ( Keep stirring, the pH value is pre-adjusted to 3.5, and 0.5% concentration of polyvinylpyrrolidone K-30 is added in advance), after the dropwise addition, continue to keep stirring, age for 24 hours, filter, and wash with deionized water three times, Dry at 80°C. The monodisperse lead iodide powder product can be obtained, and its typical morphology features are as follows figure 1 As shown, it is a flat, disc-shaped shape with a diameter of about 3 microns.

Embodiment 3

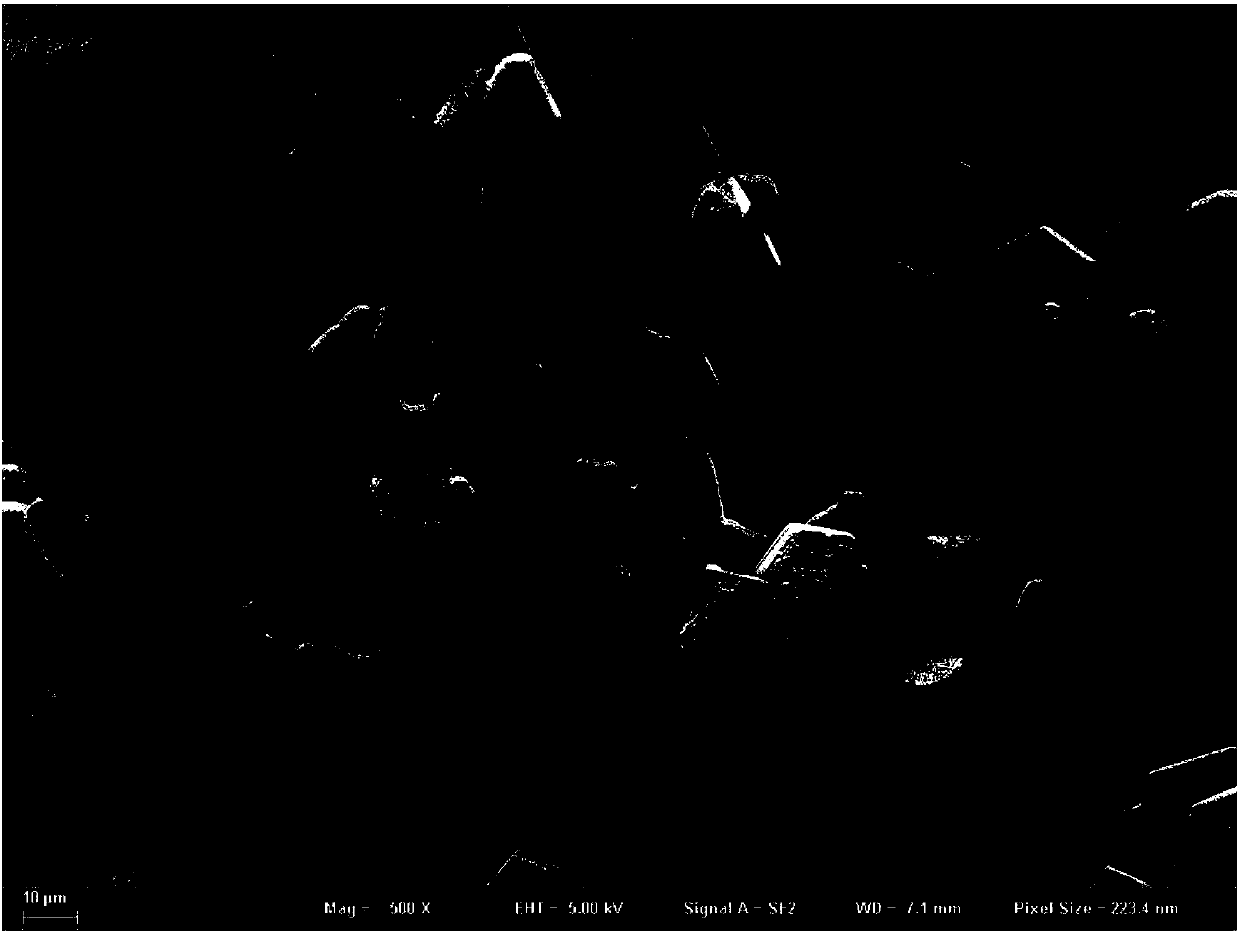

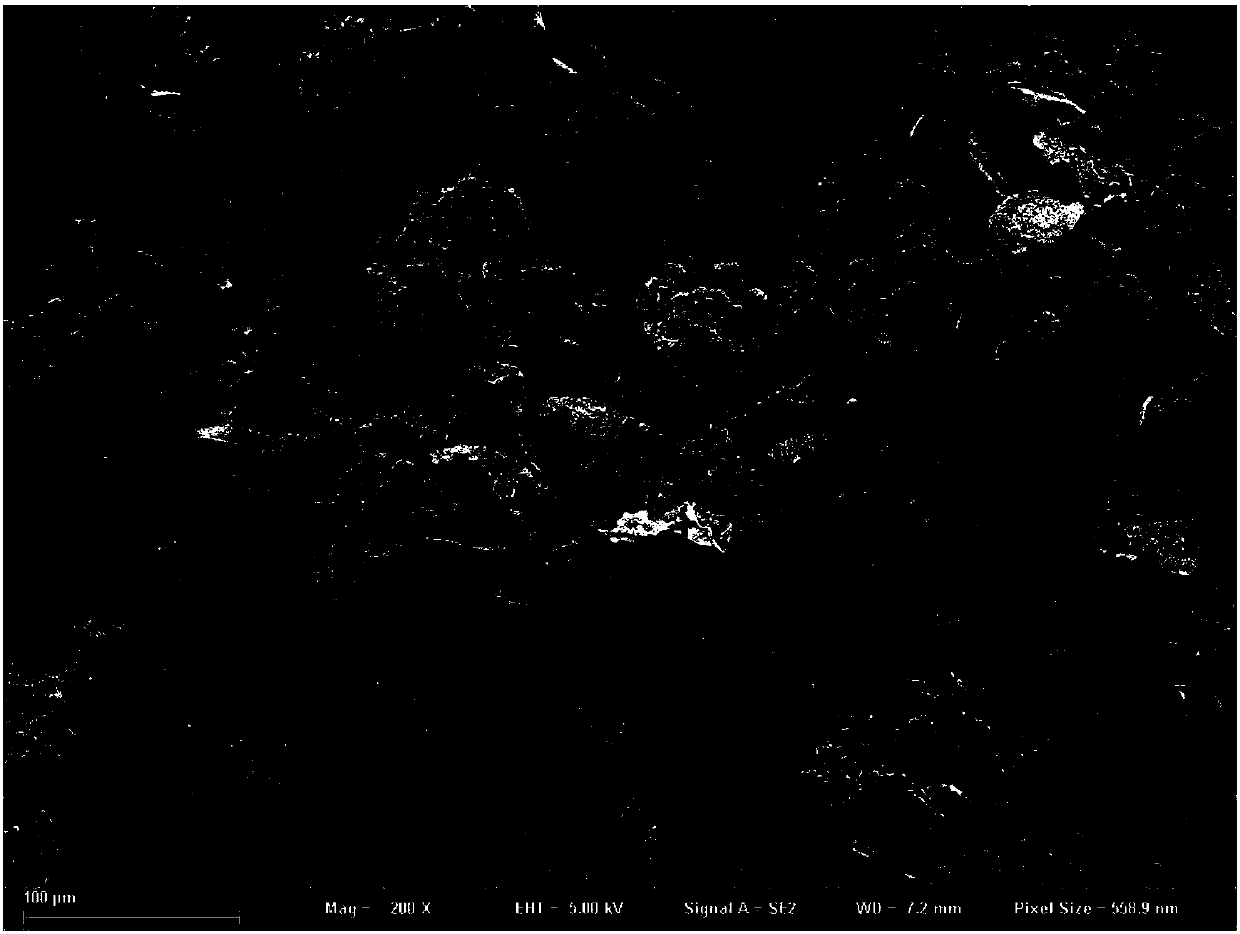

[0031] Prepare 10 liters of 0.50M lead nitrate solution and 10 liters of 0.60M ammonium iodide solution, pre-adjust their respective pH to 2.5, and then add lead nitrate dropwise to the high-speed stirring potassium iodide solution at a speed of 1 liter / minute After the dropwise addition, continue to stir and age for 18 hours, filter, wash with deionized water three times, and dry at 80 degrees Celsius. A well-dispersed lead iodide powder product can be obtained, and its typical morphology features are as follows figure 2 As shown, it is a flat shape, with a width of hundreds of microns, and a small one of about 5 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com