Organic electroluminescence material and organic light-emitting diode

A technology of electroluminescent materials and organic light-emitting devices, which is applied in the direction of organic light-emitting devices, light-emitting materials, organic semiconductor device materials, etc., can solve the problems of high driving voltage and low efficiency of devices, achieve high glass transition temperature, long-term Effects of lifetime and enhancement of hole transport ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

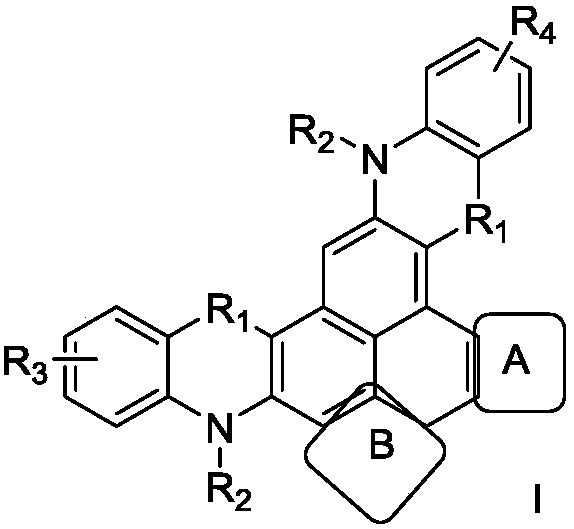

Method used

Image

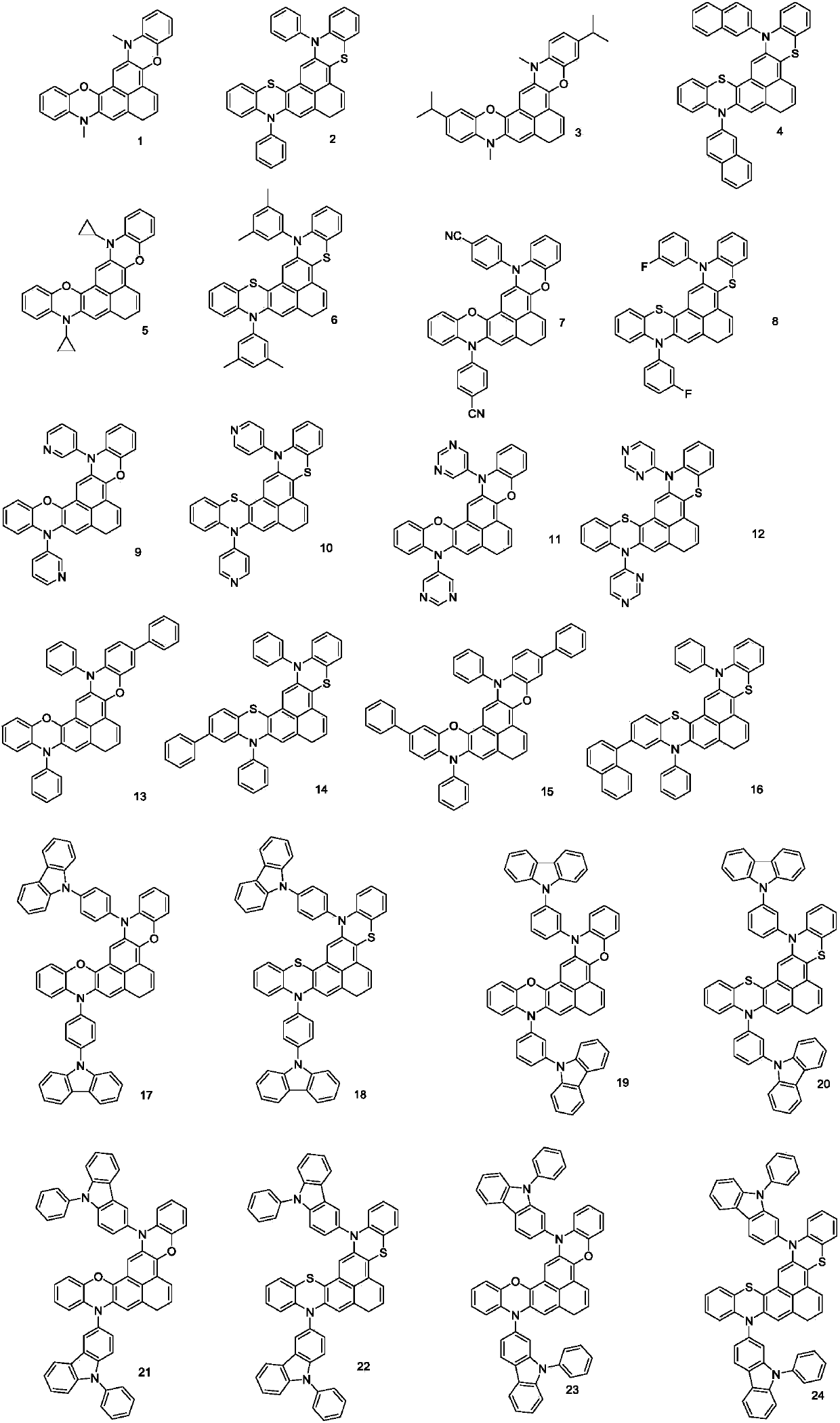

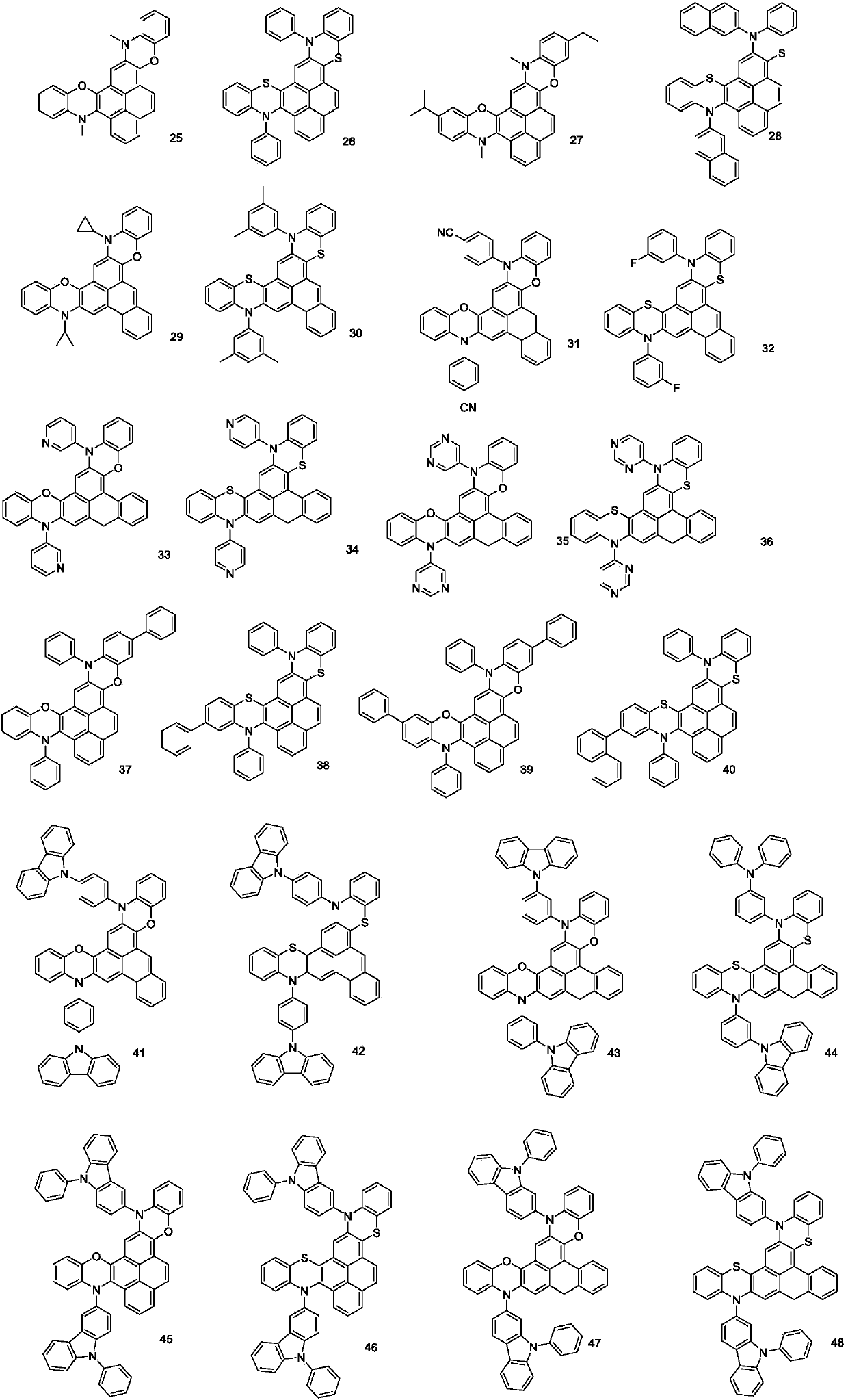

Examples

Embodiment 1

[0051] Embodiment 1: 1 synthesis of compound

[0052]

[0053] Step1. Dissolve 100mmol 1-0 and 200mmol o-nitrophenol in toluene, add 3N potassium hydroxide, 0.1N CuI, 0.1N linphenanthroline, replace with argon three times, and react at 100°C for 6h. After the reaction was completed, the reaction solution was passed through a silica gel funnel, the filtrate was washed with deionized water, concentrated, and the crude product was passed through a silica gel column to obtain 84 mmol of product 1-1.

[0054] Step2. Add 84 mmol of compound 1-1, solvent o-dichlorobenzene, 5 equivalents of triethyl sulfite, replace argon three times, raise the temperature to 165°C for 12 hours, and the reaction takes about 15 hours. The reaction solution was cooled to room temperature, and dichloromethane was added under stirring to dissolve all the product. The organic phase was washed with deionized water, distilled under pressure at 150 degrees Celsius, and concentrated to dryness to obtain a yel...

Embodiment 2

[0056] Embodiment 2: 2 synthesis of compound

[0057]

[0058] Step1. Dissolve 100mmol 1-0 and 200mmol o-nitrothiophenol in toluene, add 3 equivalents of potassium hydroxide, 0.1 equivalent of CuI, 0.1 equivalent of linphenanthroline, replace with argon three times, and react at 100°C 6h. After the reaction was completed, the reaction solution was passed through a silica gel funnel, the filtrate was washed with deionized water, concentrated, and the crude product was passed through a silica gel column to obtain 84 mmol of product 2-1.

[0059] Step2. Add 84 mmol of compound 2-1, solvent o-dichlorobenzene, 5 equivalents of triethyl sulfite, replace argon three times, raise the temperature to 165°C for 12 hours, and the reaction takes about 15 hours. The reaction solution was cooled to room temperature, and dichloromethane was added under stirring to dissolve all the product. The organic phase was washed with deionized water, distilled under pressure at 150 degrees Celsius, ...

Embodiment 3

[0061] Embodiment 3: 9 synthesis of compound

[0062] Same as Example 1, replace the methyl iodide in step3 with 3-bromopyridine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com