Efficient arsenic removal method for copper smelting high-arsenic smoke ash

A copper smelting and soot technology, which is applied in the field of efficient arsenic removal from copper smelting soot, can solve the problems of low comprehensive recovery rate of valuable elements, limited market for arsenic products, untreated sodium arsenate, etc., to save repeated production costs, Improve the arsenic precipitation rate and arsenic enrichment rate, and reduce the consumption of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

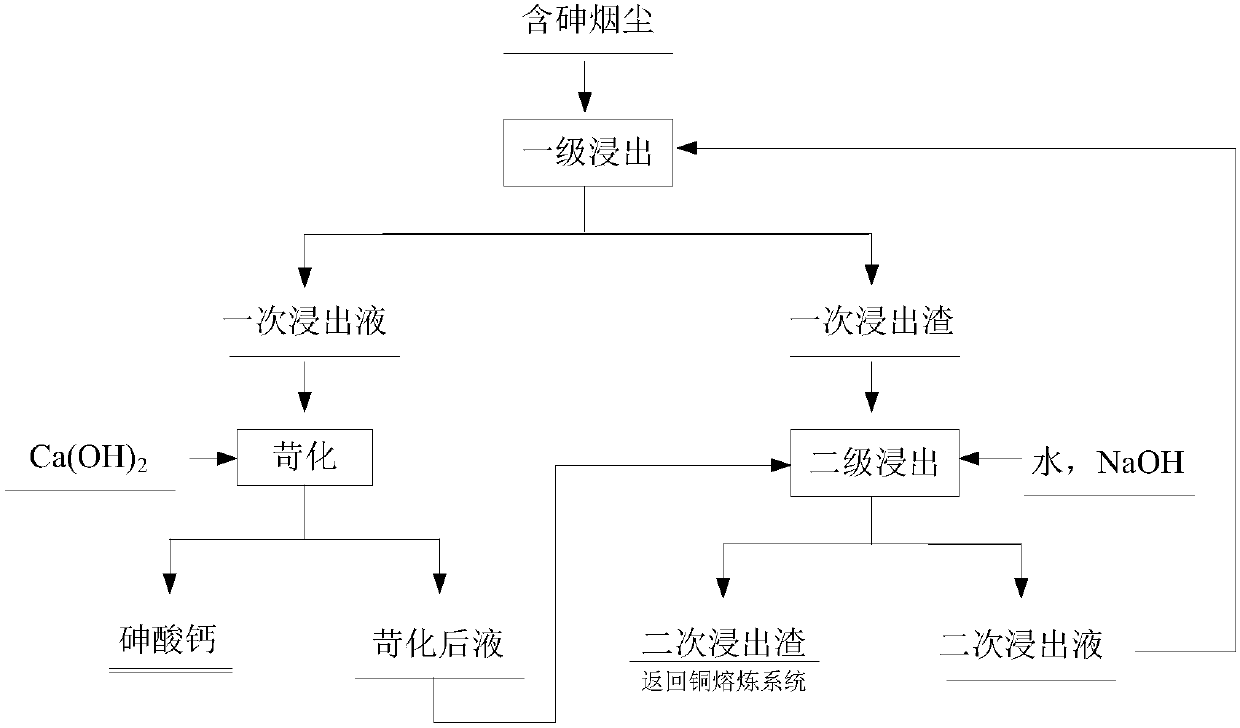

Method used

Image

Examples

Embodiment 1

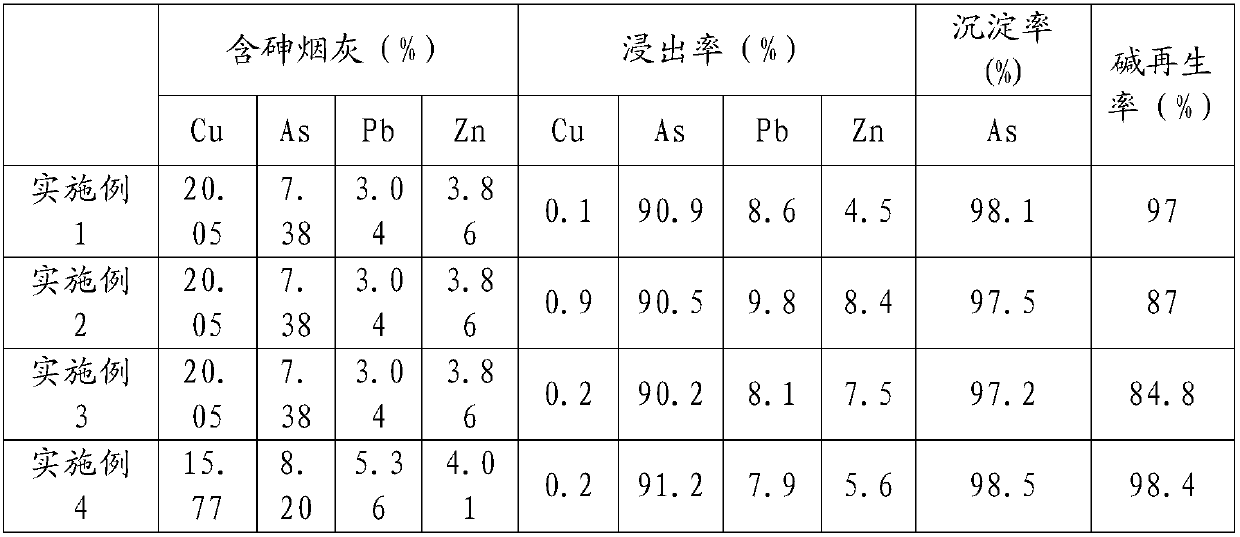

[0025] Cu: 20.05%, As: 7.38%, Pb: 3.04%, Zn: 3.86% in the copper arsenic-containing fume treated in this embodiment The treatment process and effect are as follows:

[0026] (1) The arsenic-containing dust is subjected to a first-level atmospheric pressure alkaline leaching, the NaOH concentration is 50g / L, the liquid-solid ratio is 5:1, the temperature is 80°C, and the time is 2h. Cu: 22.78%, As: 2.93%, Pb: 3.46%, Zn: 4.39% in primary leaching slag.

[0027] (2) The primary leaching slag was subjected to two-stage atmospheric pressure alkaline leaching, the liquid-solid ratio was 7:1, the NaOH concentration was 70g / L, the temperature was 85°C, and the time was 1h. In the secondary leaching slag, Cu: 31.79%, As: 1.07%, Pb: 4.41%, Zn: 5.85%; the leaching rates of arsenic, copper, lead and zinc were 90.9%, 0.1%, 8.6% and 4.5%, respectively.

[0028] (3) The obtained primary leachate is causticized, n(Ca):n(As)=3:1, the causticizing time is 2 hours, and the reaction temperature ...

Embodiment 2

[0030] Cu: 20.05%, As: 7.38%, Pb: 3.04%, Zn: 3.86% in the copper arsenic-containing fume treated in this embodiment The treatment process and effect are as follows:

[0031] (1) The arsenic-containing dust is subjected to a first-level atmospheric pressure alkaline leaching, the NaOH concentration is 40g / L, the liquid-solid ratio is 8:1, the temperature is 90°C, and the time is 1h. Cu: 22.28%, As: 3.25%, Pb: 3.21%, Zn: 4.10% in primary leaching slag.

[0032] (2) The primary leaching slag was subjected to secondary atmospheric pressure alkaline leaching, the liquid-solid ratio was 5:1, the NaOH concentration was 80g / L, the temperature was 60°C, and the time was 2h. In the secondary leaching slag, Cu: 31.53%, As: 1.11%, Pb: 4.35%, Zn: 5.61%; the leaching rates of arsenic, copper, lead and zinc were 90.5%, 0.9%, 9.8% and 8.4%, respectively.

[0033] (3) The obtained primary leachate is causticized, n(Ca):n(As)=2:1, the causticizing time is 4 hours, and the reaction temperature ...

Embodiment 3

[0035] Cu: 20.05%, As: 7.38%, Pb: 3.04%, Zn: 3.86% in the copper arsenic-containing fume treated in this embodiment The treatment process and effect are as follows:

[0036] (1) The arsenic-containing dust is subjected to a first-level atmospheric pressure alkaline leaching, the NaOH concentration is 60g / L, the liquid-solid ratio is 3:1, the temperature is 50°C, and the time is 3h. Cu: 25.04%, As: 3.15%, Pb: 3.49%, Zn: 4.48% in primary leaching slag.

[0037](2) The primary leaching slag was subjected to two-stage atmospheric pressure alkaline leaching, the liquid-solid ratio was 10:1, the NaOH concentration was 60g / L, the temperature was 90°C, and the time was 0.5h. In the secondary leaching slag, Cu: 32.02%, As: 1.20%, Pb: 4.47%, Zn: 5.71%; the leaching rates of arsenic, copper, lead and zinc were 90.2%, 0.2%, 8.1% and 7.5%, respectively.

[0038] (3) The obtained primary leachate is causticized, n(Ca):n(As)=6:1, the causticizing time is 1 hour, and the reaction temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com