Cadmium telluride solar cell with suede back contact layer and preparation method of cadmium telluride solar cell

A solar cell and back-contact technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of preparation process load, complicated process steps, difficult control, etc., to improve (VOC, improve conversion efficiency, increase bandgap width Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

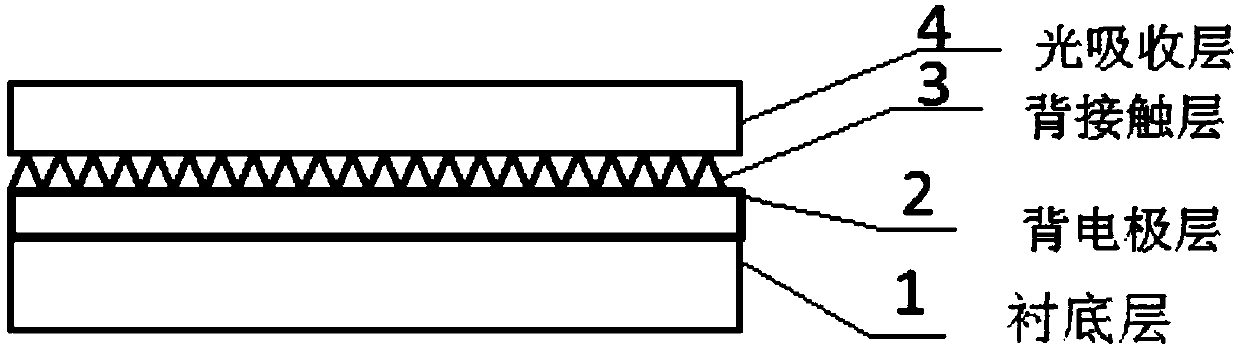

[0025] like figure 1 As shown, a cadmium telluride thin-film solar cell with a textured back contact layer is sequentially provided with a silicon dioxide substrate layer, a Mo back electrode layer, a MoSe 2 : Cu back contact layer, CdTe light absorbing layer, wherein the thickness of the substrate layer is 50nm, the thickness of the back electrode layer is 20nm, the thickness of the back contact layer is 10nm, and the thickness of the light absorbing layer is 400nm.

[0026] The preparation method of the above-mentioned cadmium telluride thin-film solar cell comprises the following steps:

[0027] (1) Use silicon dioxide as the substrate material, the thickness of the conductive film is 50nm, cut it into a size of 2.5cm×4cm, use ultrasonic cleaning method, clean with absolute ethanol solution, acetone solution, and distilled water successively, 60°C Store for later use after drying.

[0028] (2) A molybdenum back electrode layer is deposited on the substrate layer by magnet...

Embodiment 2

[0032] like figure 1 As shown, a cadmium telluride thin-film solar cell with a textured back contact layer is sequentially provided with a silicon dioxide bottom layer, a Mo back electrode layer, a MoSe 2 : Cu back contact layer, CdTe light absorbing layer, wherein the thickness of the substrate layer is 100nm, the thickness of the back electrode layer is 50nm, the thickness of the back contact layer is 20nm, and the thickness of the light absorbing layer is 500nm.

[0033] The preparation method of the above-mentioned cadmium telluride thin-film solar cell comprises the following steps:

[0034] (1) Use silicon dioxide as the substrate material, the thickness of the conductive film is 100nm, cut it into a size of 2.5cm×4cm, use ultrasonic cleaning method, clean with absolute ethanol solution, acetone solution, and distilled water successively, 60°C Store for later use after drying.

[0035] (2) A molybdenum back electrode layer is deposited on the substrate layer by magnetr...

Embodiment 3

[0039] like figure 1 As shown, a cadmium telluride thin-film solar cell with a textured back contact layer is sequentially provided with a substrate layer, a Mo back electrode layer, a MoSe 2 : Cu back contact layer, CdTe light absorbing layer, wherein the thickness of the substrate layer is 200nm, the thickness of the back electrode layer is 75nm, the thickness of the back contact layer is 30nm, and the thickness of the light absorbing layer is 600nm.

[0040] The preparation method of the above-mentioned cadmium telluride thin-film solar cell comprises the following steps:

[0041](1) Use silicon dioxide as the substrate material, the thickness of the conductive film is 200nm, cut it into a size of 2.5cm×4cm, use ultrasonic cleaning method, clean with absolute ethanol solution, acetone solution, and distilled water successively, at 60°C Store for later use after drying.

[0042] (2) A molybdenum back electrode layer is deposited on the substrate layer by magnetron sputteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com