Composite material photocatalyst for modifying by utilizing carbon dots, and preparation method and application of photocatalyst

A photocatalyst and composite material technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of destroying the balance of the ecosystem, non-point source pollution, antibiotic hazards, etc., and achieve green environmental protection and high efficiency The effect of pollution treatment technology and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

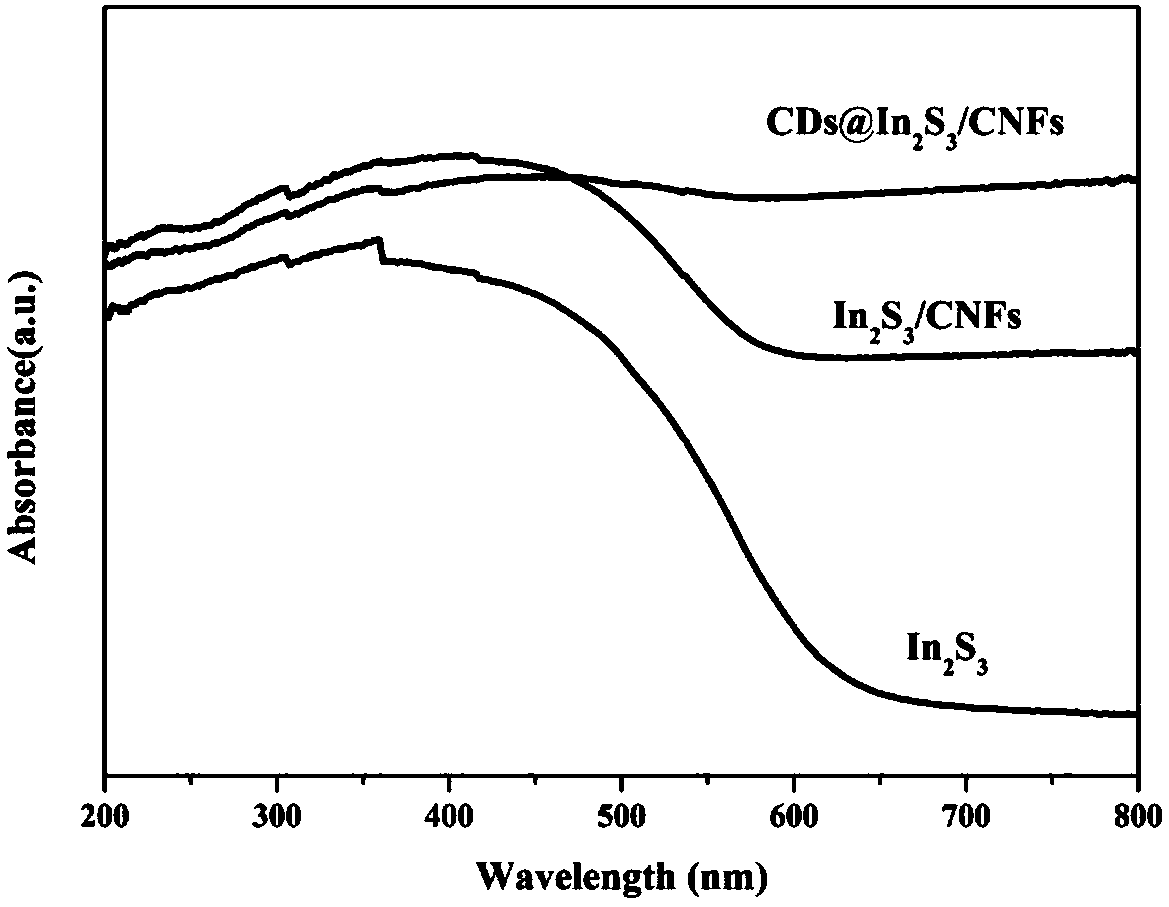

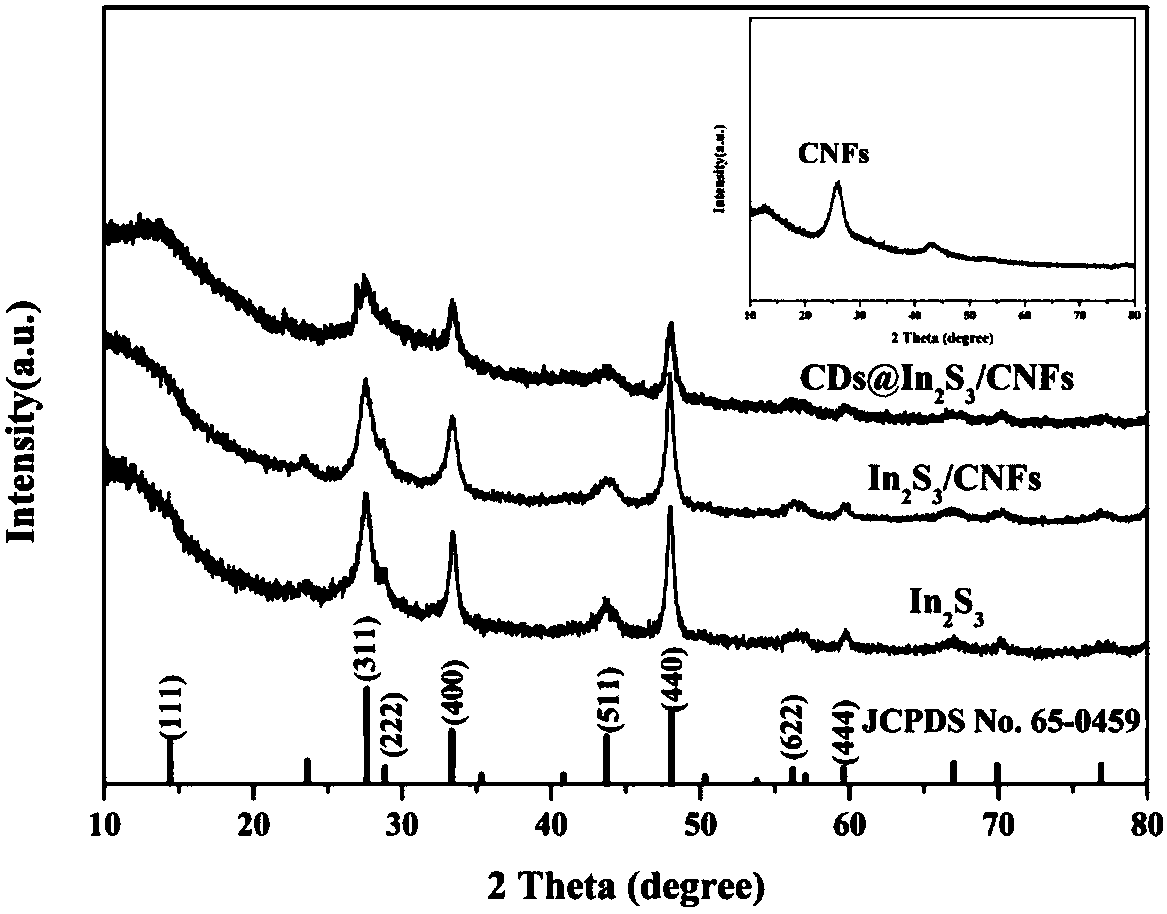

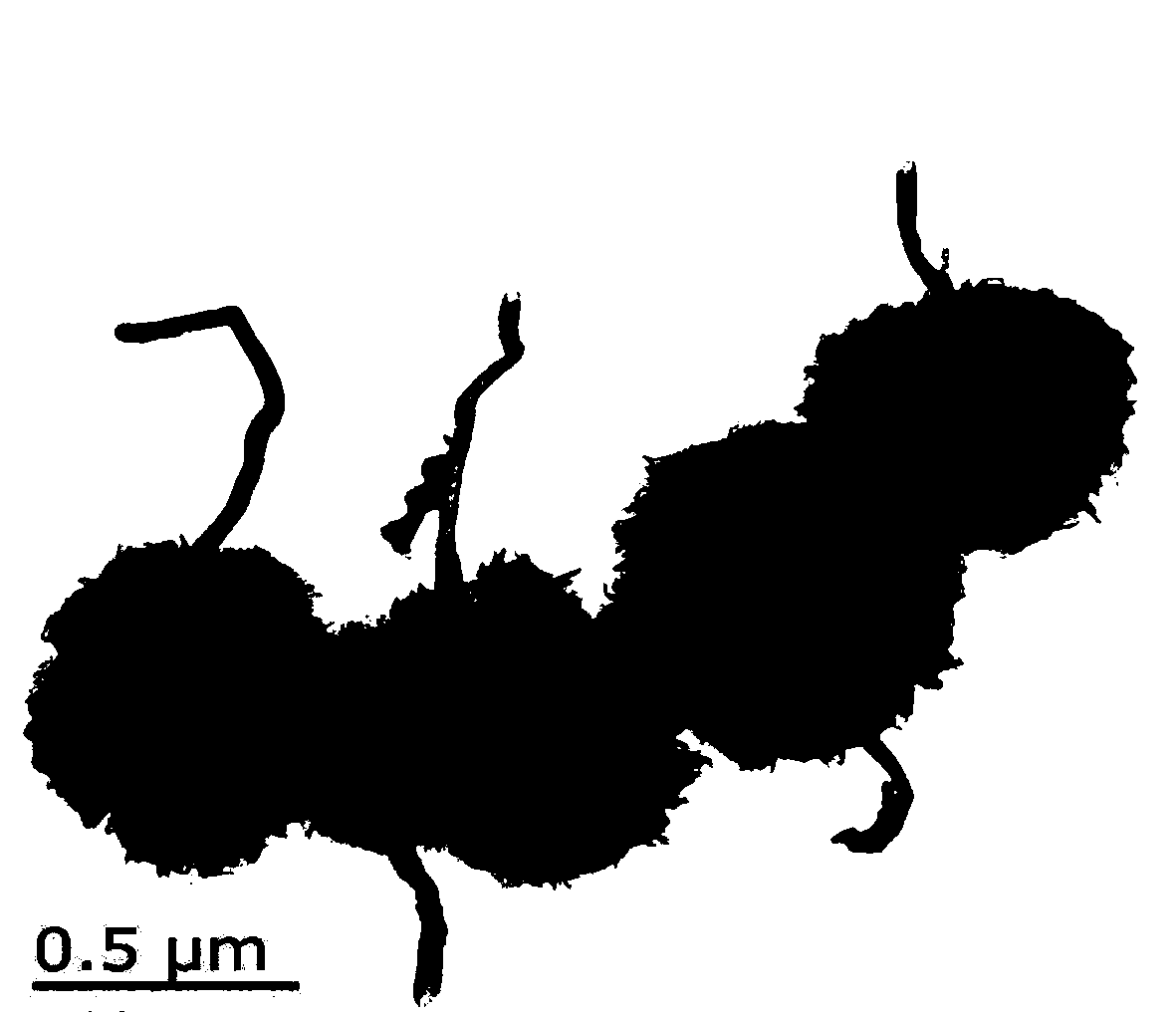

[0026] (1)In 2 S 3 / Preparation of CNFs precursor:

[0027] Weigh 0.15g InCl 3 4H 2 Put O (indium chloride tetrahydrate) and 0.24g L-cysteine into a glass beaker, add deionized water to dissolve it completely, stir magnetically, then add 0.15g carbon nanofibers, stir and sonicate to make it evenly mixed , then transfer the mixture to a 100mL hydrothermal reactor, and put it in an oven for calcination at 160°C for 12h, and the solid collected by filtration and washing is In 2 S 3 / CNFs precursor;

[0028] (2)CDs@In 2 S 3 Preparation of / CNFs composite photocatalyst:

[0029] Weigh 1.0g of citric acid and place it in a glass beaker, add 0.335mL of ethylenediamine and 10mL of deionized water, stir magnetically and heat with 800W microwave, the resulting solution is carbon dots; then add 0.5g of In 2 S 3 / CNFs precursor was added to 2g of the above-mentioned mixed solution, fully magnetically stirred and placed in a 50mL reaction kettle, heated at 120°C, cooled to roo...

Embodiment 2

[0032] (1)In 2S 3 / Preparation of CNFs precursor:

[0033] Weigh 0.30g InCl 3 4H 2 Put O (indium chloride tetrahydrate) and 0.48g L-cysteine into a glass beaker, add deionized water to dissolve it completely, stir magnetically, then add 0.15g carbon nanofibers, stir and sonicate to make it evenly mixed , then transfer the mixture to a 100mL hydrothermal reactor, and put it in an oven for calcination at 160°C for 12h, and the solid collected by filtration and washing is In 2 S 3 / CNFs precursor;

[0034] (2)CDs@In 2 S 3 Preparation of / CNFs composite photocatalyst:

[0035] Weigh 1.0g of citric acid and place it in a glass beaker, add 0.335mL of ethylenediamine and 10mL of deionized water, stir magnetically and heat with 800W microwave, the resulting solution is carbon dots; then add 0.5g of In 2 S 3 / CNFs precursor was added to 2g of the above-mentioned mixed solution, fully magnetically stirred and placed in a 50mL reaction kettle, heated at 120°C, cooled to room...

Embodiment 3

[0038] (1)In 2 S 3 / Preparation of CNFs precursor:

[0039] Weigh 0.45g InCl 3 4H 2 Put O (indium chloride tetrahydrate) and 0.72g L-cysteine into a glass beaker, add deionized water to dissolve it completely, stir magnetically, then add 0.15g carbon nanofibers, stir and sonicate to make it evenly mixed , then transfer the mixture to a 100mL hydrothermal reactor, and put it in an oven for calcination at 160°C for 12h, and the solid collected by filtration and washing is In 2 S 3 / CNFs precursor;

[0040] (2)CDs@In 2 S 3 Preparation of / CNFs composite photocatalyst:

[0041] Weigh 1.0g of citric acid and place it in a glass beaker, add 0.335mL of ethylenediamine and 10mL of deionized water, stir magnetically and heat with 800W microwave, the resulting solution is carbon dots; then add 0.5g of In 2 S 3 / CNFs precursor was added to 2g of the above-mentioned mixed solution, fully magnetically stirred and placed in a 50mL reaction kettle, heated at 120°C, cooled to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com