Preparation method for foaming-cement reinforced SiO2-TiO2 composite aerogel material

A composite aerogel and foamed cement technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of low use temperature, high thermal conductivity, inability to use high-temperature thermal equipment, etc., to improve high-temperature heat insulation Performance, good occlusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

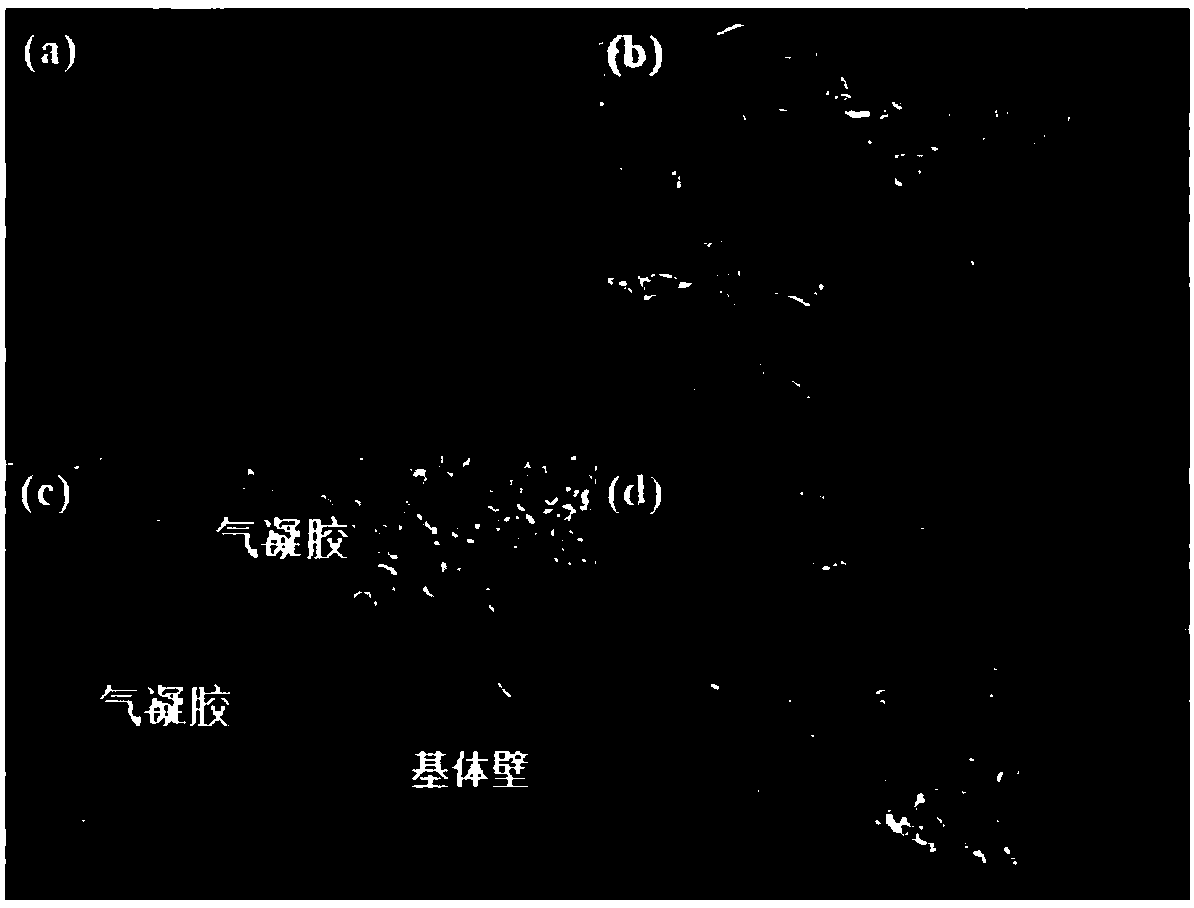

Image

Examples

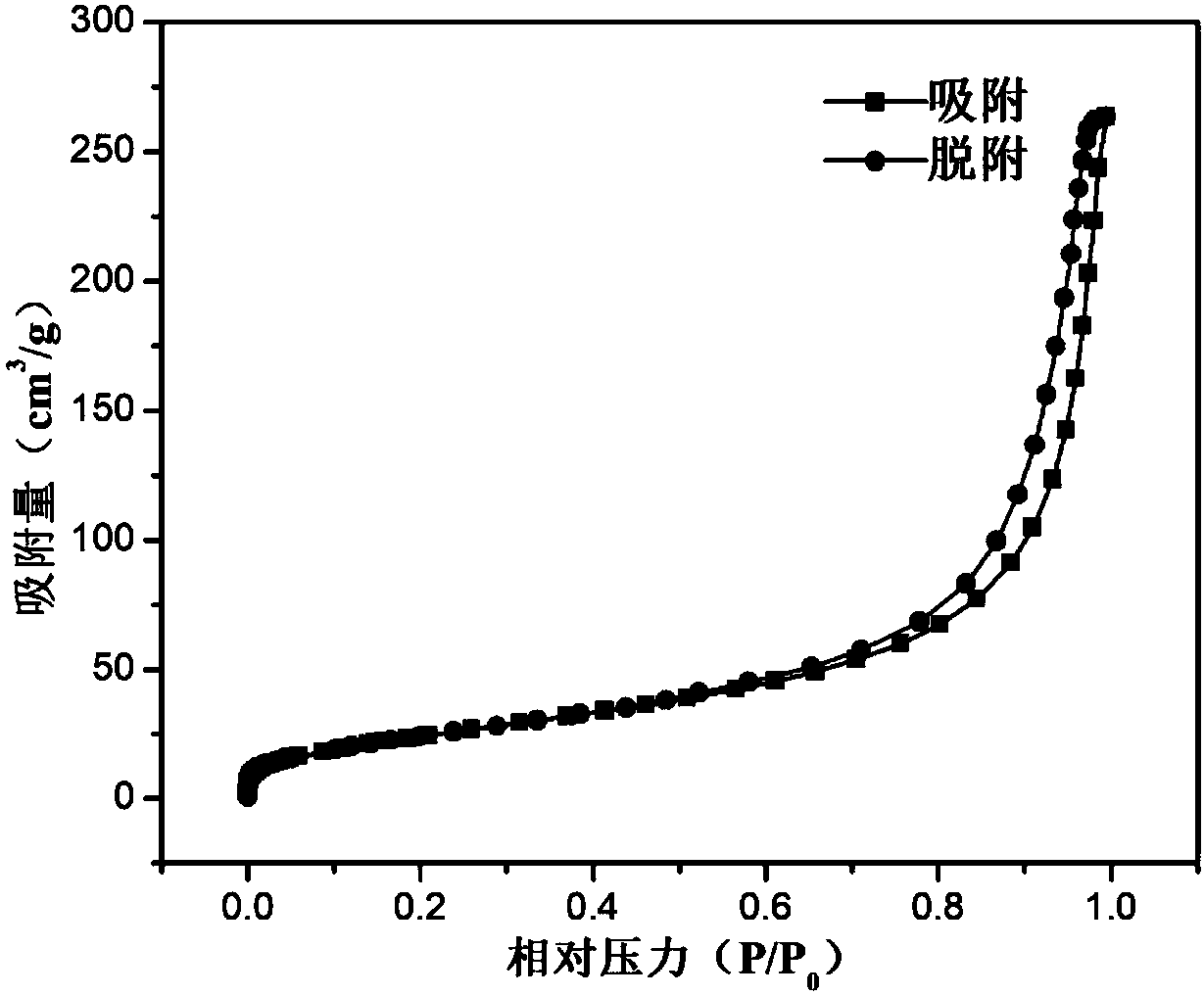

example 1

[0038] Add 80ml of TEOS, 144ml of absolute ethanol, and 40ml of deionized water into the beaker, stir well, add 1.2ml of ethanol solution of 3mol / L nitric acid to adjust the pH to 3, seal it, heat at 50°C and stir at 600r / min for 1h to obtain SiO 2 Sol. Add 16ml of TBOT and 36ml of deionized ethanol into the beaker, after stirring, add 1.3ml of ethanol solution of 3mol / L nitric acid to adjust the pH to 3.5 to obtain a solution ①; add 10ml of dehydrated ethanol and 4ml of deionized water into the beaker, add 3mol / L nitric acid ethanol solution 0.1ml to adjust the pH to 3.5 to obtain solution ②, slowly add solution ② to solution ①, and stir vigorously to form TiO 2 Sol. Get 260ml silica sol and 65ml titanium sol and mix evenly, use the ethanol solution of 105ml ammonia water (V 浓氨水 :V 乙醇 =1:45) to get SiO after adjusting the pH to 6 2 -TiO 2 The composite sol is ready for use. Set the density to 0.28g / cm 3 , Thermal conductivity at room temperature is 0.095W·m -1 ·K -...

example 2

[0041]Add 100ml of TEOS, 120ml of absolute ethanol, and 20ml of deionized water into the beaker, stir well, add 2.3ml of ethanol solution of 1mol / L hydrochloric acid to adjust the pH to 4, seal it, heat at 40°C and stir at 300r / min for 2h to obtain SiO 2 Sol. Add 18ml of TBOT and 30ml of absolute ethanol to a beaker, after stirring, add 2ml of ethanol solution of 1mol / L hydrochloric acid to adjust the pH to 4 to obtain a solution ①; add 20ml of absolute ethanol and 4ml of deionized water into a beaker, add 1mol / L 0.2ml ethanol solution of L hydrochloric acid to adjust the pH to 3.5 to obtain solution ②, slowly add solution ② to solution ①, and stir vigorously to form TiO 2 Sol. Get 240ml of silica sol and 72ml of titanium sol to mix and stir evenly, use the ethanol solution of 78ml of ammonia water (V 浓氨水 :V 乙醇 =1:55) to get SiO after adjusting the pH to 7 2 -TiO 2 The composite sol is ready for use. Set the density to 0.81g / cm 3 , Thermal conductivity at room temperat...

example 3

[0044] Add 65ml of TEOS, 88ml of absolute ethanol, and 25ml of deionized water into the beaker. After stirring well, add 2.5ml of ethanol solution of 2mol / L sulfuric acid to adjust the pH to 4. After sealing, heat at 45°C and stir at 450r / min for 1.5h Get SiO 2 Sol. Add 20ml of TBOT and 30ml of deionized ethanol in a beaker, after stirring, add 2.8ml of ethanol solution of 2mol / L sulfuric acid to adjust the pH to 3 to obtain a solution①; add 18ml of dehydrated ethanol and 4.2ml of deionized water into a beaker, stir and add 0.2ml of 3mol / L ethanol solution of sulfuric acid to adjust the pH to 4 to obtain solution ②, slowly add solution ② to solution ①, and stir vigorously to form TiO 2 Sol. Get 175ml-silica sol mixed with 70ml titanium sol and stir evenly, use the ethanol solution of 65ml ammonia water (V 浓氨水 :V 乙醇 =1:50) to get SiO after adjusting the pH to 6 2 -TiO 2 The composite sol is ready for use. Set the density to 0.63g / cm 3 , Thermal conductivity at room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com