A method and equipment for continuous crystallization, crystal growth, dewaxing and refining to improve the quality of vegetable oil

A vegetable oil and dewaxing technology, which is applied in the fields of fat oil/fat refining, fat oil/fat separation, fat production, etc. It can solve the problems of strong crystal damage, poor and uneven heat conduction efficiency, and increased crystal formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] A method for continuous crystallization, crystal growth, dewaxing and refining to improve the quality of vegetable oil, comprising the following steps:

[0086] Step 1, eight-stage cooling crystallization step by step

[0087] ① Control the temperature of the oil in the heat exchanger 1 from 105°C to 120°C to 30°C to 100°C, pump it into the buffer tank I2 to stir and temporarily store, the buffer tank I3 is an isothermal insulation tank for incoming materials, and the stirring speed is 100rpm / min - 1200rpm / min, add 0-3% of oil weight crystal / filter aid and / filter aid to the buffer tank I3.

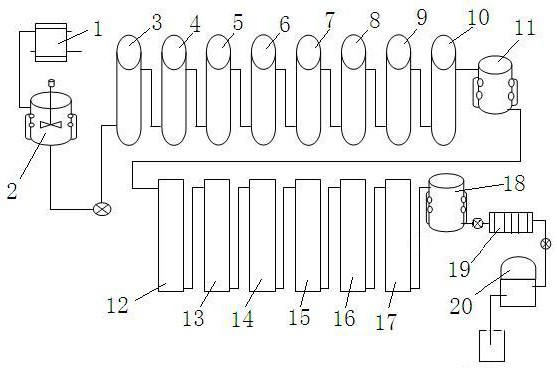

[0088] ② Pump the vegetable oil in the buffer tank I2 into the eight-stage cooling dewaxing tank group A1 3, A2 4, A3 5, A4 6, A5 7, A6 8, A7 9, A8 10 in series, each level (tank) See Table 1 for the single oil tank capacity, control temperature range, stirring speed, nitrogen flux, and ventilation time interval control.

[0089] Table 1

[0090]

[0091] The temperature range...

Embodiment 2

[0105] The equipment used in the refining method includes a buffer tank I2, and the buffer tank I2 is connected with an eight-stage cooling dewaxing tank, wherein the eight-stage cooling dewaxing tank includes A1 3, A2 4, A3 5, A4 6 in series , A5 7, A6 8, A7 9, A8 The 10-level tanks are connected to the sixth-level constant temperature crystal growth tanks through the buffer tank II, and the six-level constant temperature crystal growth tanks include B1 12, B2 13, B3 14, B415, B5 16, B6 Grade 17 tank is connected to filter through buffer tank III.

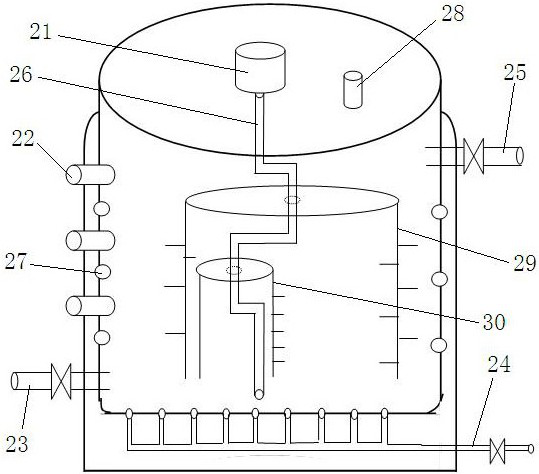

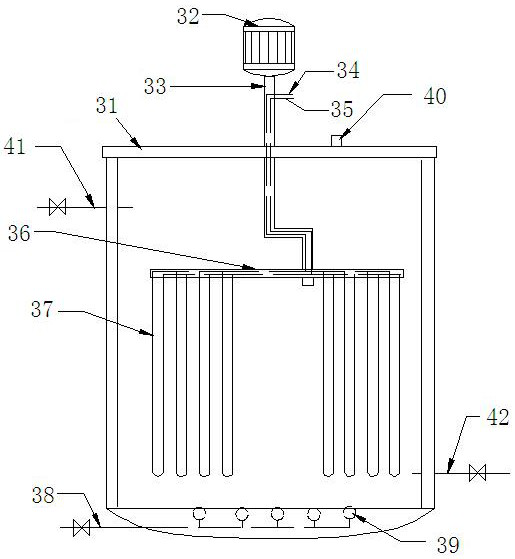

[0106] The cooling dewaxing tank or constant temperature crystal growth tank (ie A1 3, A2 4, A3 5, A4 6, A5 7, A6 8, A7 9, A810, B1 12, B2 13, B3 14, B4 15, B5 16 or B6 17), the first structure is: including a tank body, a stirring motor 21 is arranged on the top of the tank body, and the slow stirring rate provided by the stirring motor 21 is adjustable by frequency conversion, and the speed can be adjusted from 1 rpm to 50 rpm, ...

Embodiment 3

[0127] A method for continuous crystallization, crystal growth, dewaxing and refining to improve vegetable oil quality, the difference from Example 1 is that

[0128] In step 1,

[0129] Control the temperature of the oil from 110°C to 60°C in the heat exchanger 1, pump it into the buffer tank I2 to stir and temporarily store, the buffer tank I3 is an isothermal insulation tank for incoming materials, the stirring speed is 800rpm / min, add oil to the buffer tank I3 1% by weight crystallization / drainage aid, crystal / drainage aid is diatomaceous earth.

[0130] Grease stays at each temperature (tank) for 2h-4h.

[0131] The eight-level temperature control is A1 3—>26°C, A2 4—24°C, A3 5—19°C, A4 6—15.5°C, A57—12.5°C, A6 8—10°C, A7 9—8°C, A8 10 -3~6℃.

[0132] Preferably, the ventilation intervals are as shown in Table 3:

[0133] table 3

[0134]

[0135] In step 2,

[0136] The stirring speed of the buffer tank II11 is 30rpm / min, and 1.5% of the oil weight is added to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com