Titanium alloy and preparation method thereof

A technology of titanium alloy and intermediate alloy, applied in the field of titanium alloy and its preparation, to achieve the effect of improving yield and service life, good cold and hot processing performance, and easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Preparation of various formula titanium alloy materials

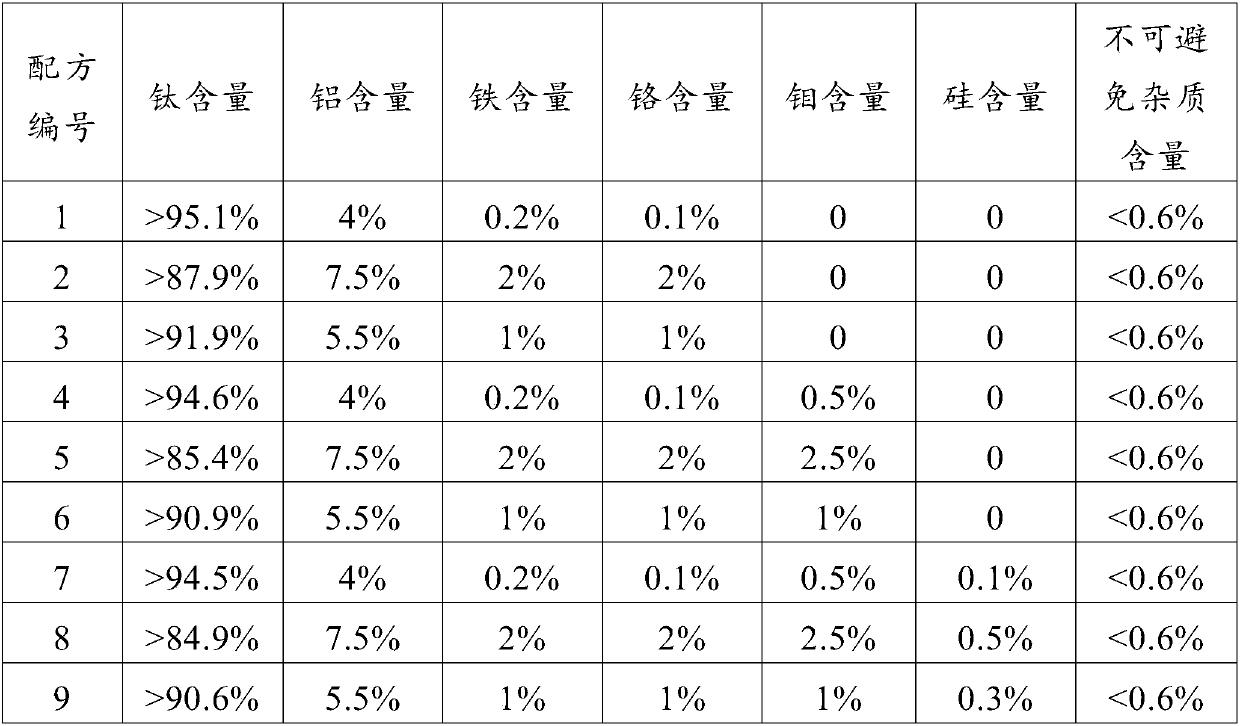

[0024] Adopt the following method to prepare the titanium alloy material of each formula composition in Table 1 (the content of each substance is the weight percent content; All do not contain vanadium in each formula titanium alloy material; The total amount of carbon, hydrogen, oxygen, nitrogen in each formula unavoidable impurity The weight percentages are all less than 0.4% of the total weight of the titanium alloy).

[0025] Alloy materials are prepared according to the composition of each formula, and the required sponge titanium, aluminum-iron master alloy, aluminum-chromium master alloy, aluminum-molybdenum master alloy, aluminum-silicon master alloy are mixed and pressed into electrodes, and smelted twice in a vacuum consumable furnace Or obtain the alloy ingot three times (smelting vacuum degree requirement is lower than 1Pa). After peeling the ingot, cutting off the riser and tail, the b...

Embodiment 2

[0028] Embodiment 2: The mechanical property detection of each formula titanium alloy material

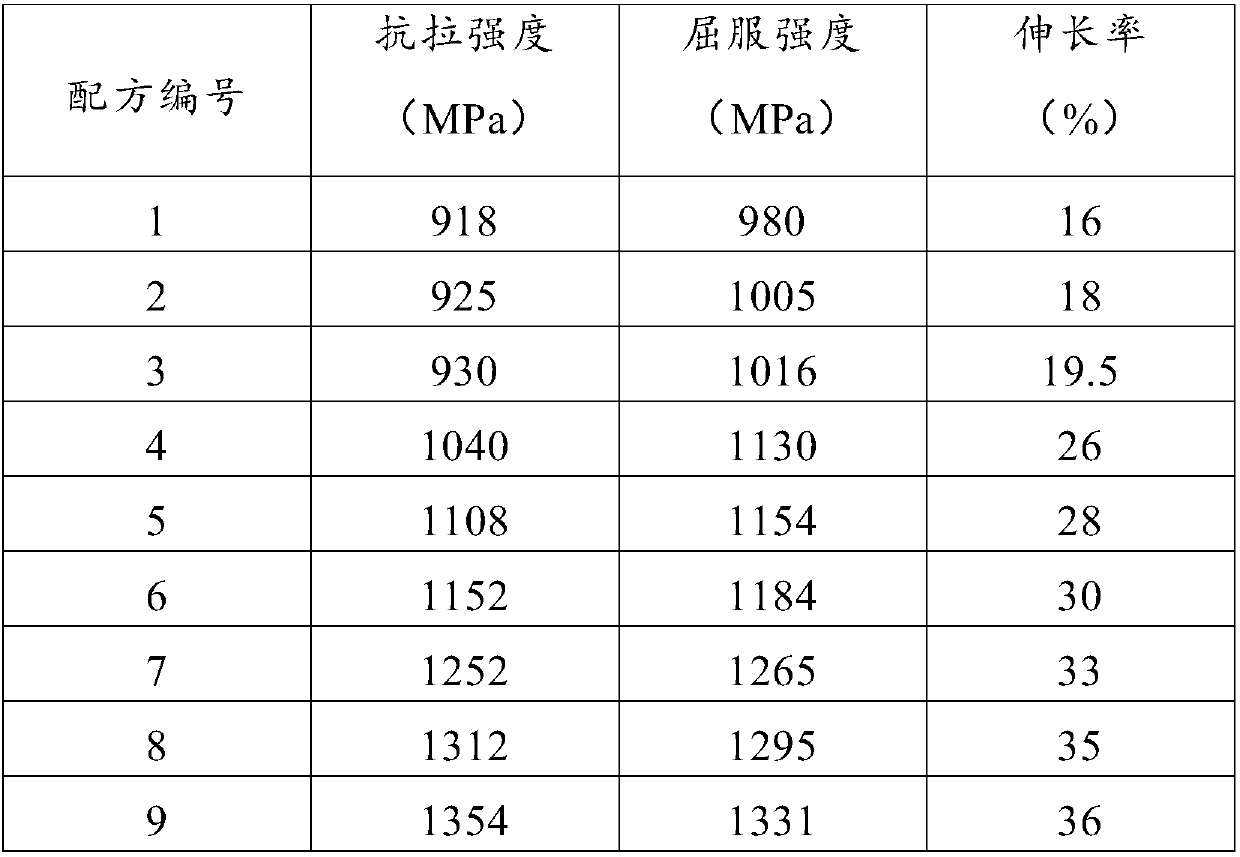

[0029] According to the national standard GB / T 228.1-2010, the titanium alloy rods prepared according to the formulations of Example 1 were made into tensile samples, and comprehensive mechanical properties were tested at room temperature. The test results are shown in Table 2 below.

[0030] Table 2 Mechanical property test results of each formula titanium alloy material

[0031]

[0032] It can be seen from the data in Table 2 above that the titanium alloy of the present invention has high strength and obviously better mechanical properties.

Embodiment 3

[0033] Example 3: Comprehensive performance detection of various formula titanium alloy materials except mechanical properties

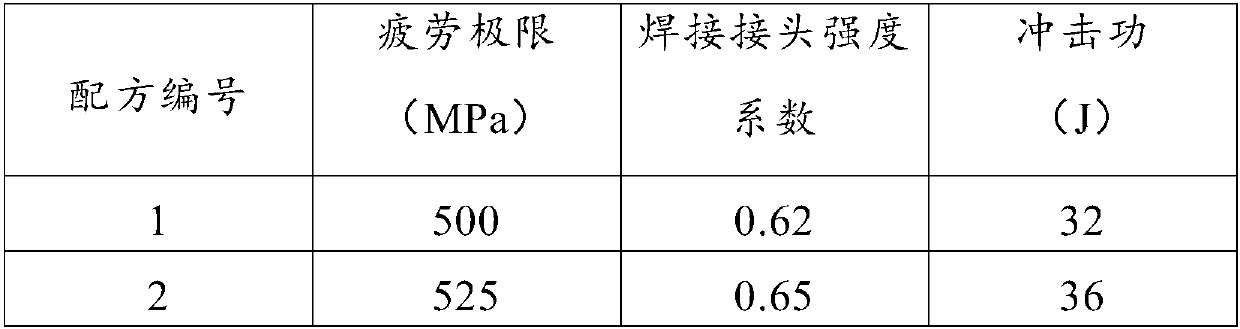

[0034] According to the relevant detection standards of national standard GB / T 228-2002, NB / T 47014-2011 (JB / 4708), GB / T 229-2007, the titanium alloy material of each formula of embodiment 1 is made into test specimen, respectively The fatigue limit, strength coefficient of welded joints and impact energy were tested, and the test results are shown in Table 3 below.

[0035] Table 3 The comprehensive performance test results of each formula titanium alloy material except mechanical properties

[0036]

[0037]

[0038] It can be seen from the data in Table 3 above that the titanium alloy material of the present invention has significantly better comprehensive properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com