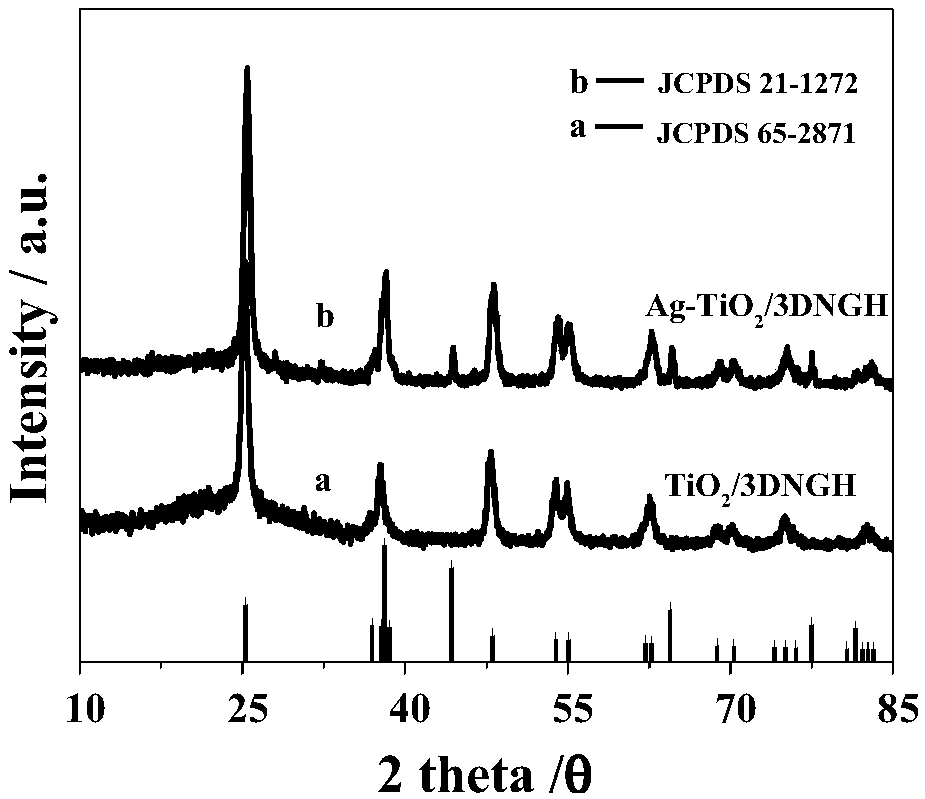

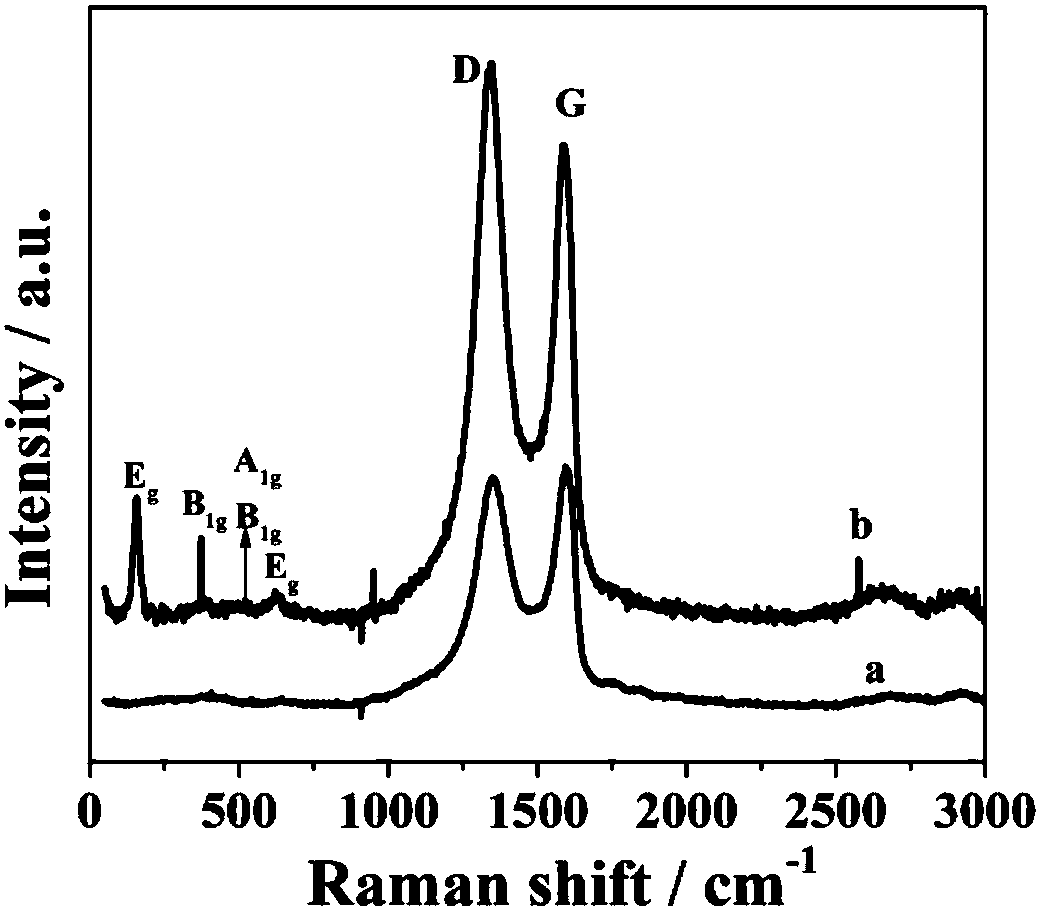

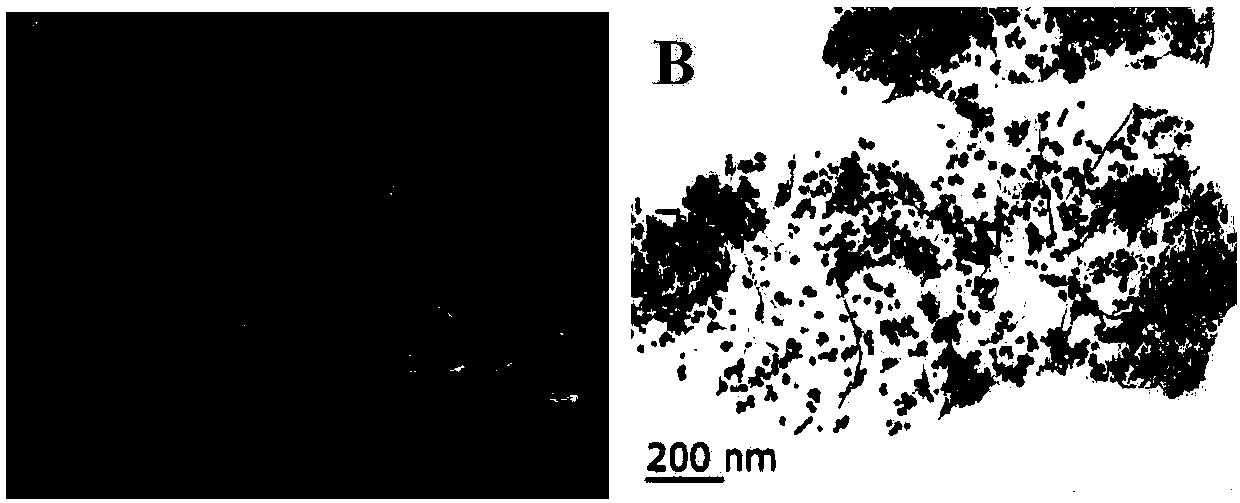

Preparation method and applications of Ag/TiO2-supported nitrogen-doped three-dimensional graphene aerogel

A technology of graphene airgel and titanium dioxide, which is applied in the direction of airgel preparation, graphene, chemical instruments and methods, etc., to achieve the effect of thrombin detection and response improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Preparation of graphene oxide (GO)

[0033] First, natural flake graphite powder and potassium nitrate are added to concentrated sulfuric acid in a mass ratio (2:1) and cooled to about 0°C.

[0034] Wherein, the add-on of concentrated sulfuric acid is according to natural flake graphite powder: the ratio of concentrated sulfuric acid=1.0 (g):50.0 (mL); The add-on of potassium permanganate is added according to mass ratio potassium permanganate: natural flake graphite powder=6 The reaction system was reacted for 3-4 hours (in ice bath at 0°C); then in an oil bath at 30°C for 1 hour, the reactant was muddy; then the above reactant was stirred in an ice-water bath for 5 minutes, and then double distilled water was added 100mL; then stirred at 70°C for 3 hours, the reactant was brownish-yellow mud; finally, 300mL hydrogen peroxide (5%) was first slowly and then quickly added to the reaction system to react for 5-30min. Afterwards, 500 mL of concentrated hydrochloric aci...

Embodiment 2

[0042] 1) Preparation of graphene oxide (GO)

[0043] First, natural flake graphite powder and potassium nitrate are added to concentrated sulfuric acid in a mass ratio (2:1) and cooled to about 0°C.

[0044] Wherein, the add-on of concentrated sulfuric acid is according to natural flake graphite powder: the ratio of concentrated sulfuric acid=1.0 (g):50.0 (mL); The add-on of potassium permanganate is added according to mass ratio potassium permanganate: natural flake graphite powder=6 The reaction system was reacted for 3-4 hours (in ice bath at 0°C); then in an oil bath at 30°C for 1 hour, the reactant was muddy; then the above reactant was stirred in an ice-water bath for 5 minutes, and then double distilled water was added 100mL; then stirred at 70°C for 3 hours, the reactant was brownish-yellow mud; finally, 300mL hydrogen peroxide (5%) was first slowly and then quickly added to the reaction system to react for 5-30min. Afterwards, 500 mL of concentrated hydrochloric aci...

Embodiment 3

[0052] 1) Preparation of graphene oxide (GO)

[0053] First, natural flake graphite powder and potassium nitrate are added to concentrated sulfuric acid in a mass ratio (2:1) and cooled to about 0°C.

[0054] Wherein, the add-on of concentrated sulfuric acid is according to natural flake graphite powder: the ratio of concentrated sulfuric acid=1.0 (g):50.0 (mL); The add-on of potassium permanganate is added according to mass ratio potassium permanganate: natural flake graphite powder=6 The reaction system was reacted for 3-4 hours (in ice bath at 0°C); then in an oil bath at 30°C for 1 hour, the reactant was muddy; then the above reactant was stirred in an ice-water bath for 5 minutes, and then double distilled water was added 100mL; then stirred at 70°C for 3 hours, the reactant was brownish-yellow mud; finally, 300mL hydrogen peroxide (5%) was first slowly and then quickly added to the reaction system to react for 5-30min. Afterwards, 500 mL of concentrated hydrochloric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com