Corn baking flour and method for preparing crisp biscuits by using corn baking flour

A technology for crispy biscuits and corn flour is applied to the preparation of crispy biscuits and corn baking flour, and can solve the problems of cumbersome preparation methods, no reference value, poor feasibility, etc., and achieves simple and easy process and considerable profit margins. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

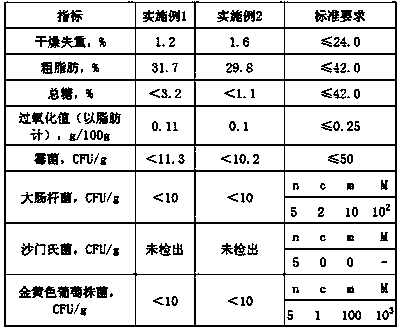

Embodiment 1

[0025] The method for preparing corn flour for baking specifically includes the following steps.

[0026] (1) Select high-quality corn (preferably colloidal corn) with a water content of 15% at room temperature and pressure to remove impurities, peel, and germ, and grind it into a fine powder to 110 mesh to obtain raw powder for later use.

[0027] (2) Select high-quality corn kernels (preferably colloidal corn) with a water content of 15% at room temperature and pressure to remove impurities, peel, and remove germ; place them in a single-screw extruder with an extruding speed of 1500r / min and an extruding temperature of 180 ℃, the water content after puffing treatment is 10%, the extruded cylindrical material is cut into granules (particle size 10-12mm) with a rotary knife, and ground into fine powder to 110 mesh to obtain cooked powder for later use.

[0028] (3) Add cornstarch into water, stir evenly, the starch concentration is 86%, put it in a single-screw extruder, the s...

Embodiment 2

[0037] The method for preparing corn flour for baking specifically includes the following steps.

[0038] (1) Select high-quality corn (preferably colloidal corn) with a water content of 15% at room temperature and pressure to remove impurities, peel, and germ, and grind it into a fine powder to 110 mesh to obtain raw powder for later use.

[0039] (2) Select high-quality corn kernels (preferably colloidal corn) with a water content of 15% at room temperature and pressure to remove impurities, peel, and remove germ; place them in a single-screw extruder with an extruding speed of 1200r / min and an extruding temperature of 180 °C, the moisture content after puffing treatment is 10.5%, and the extruded cylindrical material is cut into granular shape (particle size is 10-12mm) with a rotary knife, and ground into fine powder to 110 mesh to obtain cooked powder for later use.

[0040] (3) Add cornstarch into water, stir evenly, the starch concentration is 85%, put it in a single-sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com