Highly-antioxidant highly-crosslinked ultra-high molecular weight polyethylene artificial joint material and preparation method thereof

An ultra-high molecular weight, artificial joint technology, applied in the field of high anti-oxidative and high cross-linked ultra-high molecular weight polyethylene artificial joint material and its preparation field, can solve the problems of difficulty in exerting anti-oxidation effect, unfavorable mechanical properties of materials, increased chain breakage, etc. , to achieve the effect of improving antioxidant performance, meeting the conditions of use, and strong antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Specifically, the preparation method of the present invention may include the following steps.

[0034] Step A: Doping UHMWPE with Polyphenolic Antioxidants

[0035] Add ultra-high molecular weight polyethylene (UHMWPE) and polyphenolic antioxidant into isopropanol and keep stirring, and dry the resulting mixture to obtain mixed powder. Among them, polyphenolic antioxidants account for 0.05% to 0.20% of the total mass of ultra-high molecular weight polyethylene and polyphenolic antioxidants. Preferably, the polyphenolic antioxidant accounts for 0.20% of the total mass of ultra-high molecular weight polyethylene and polyphenolic antioxidant.

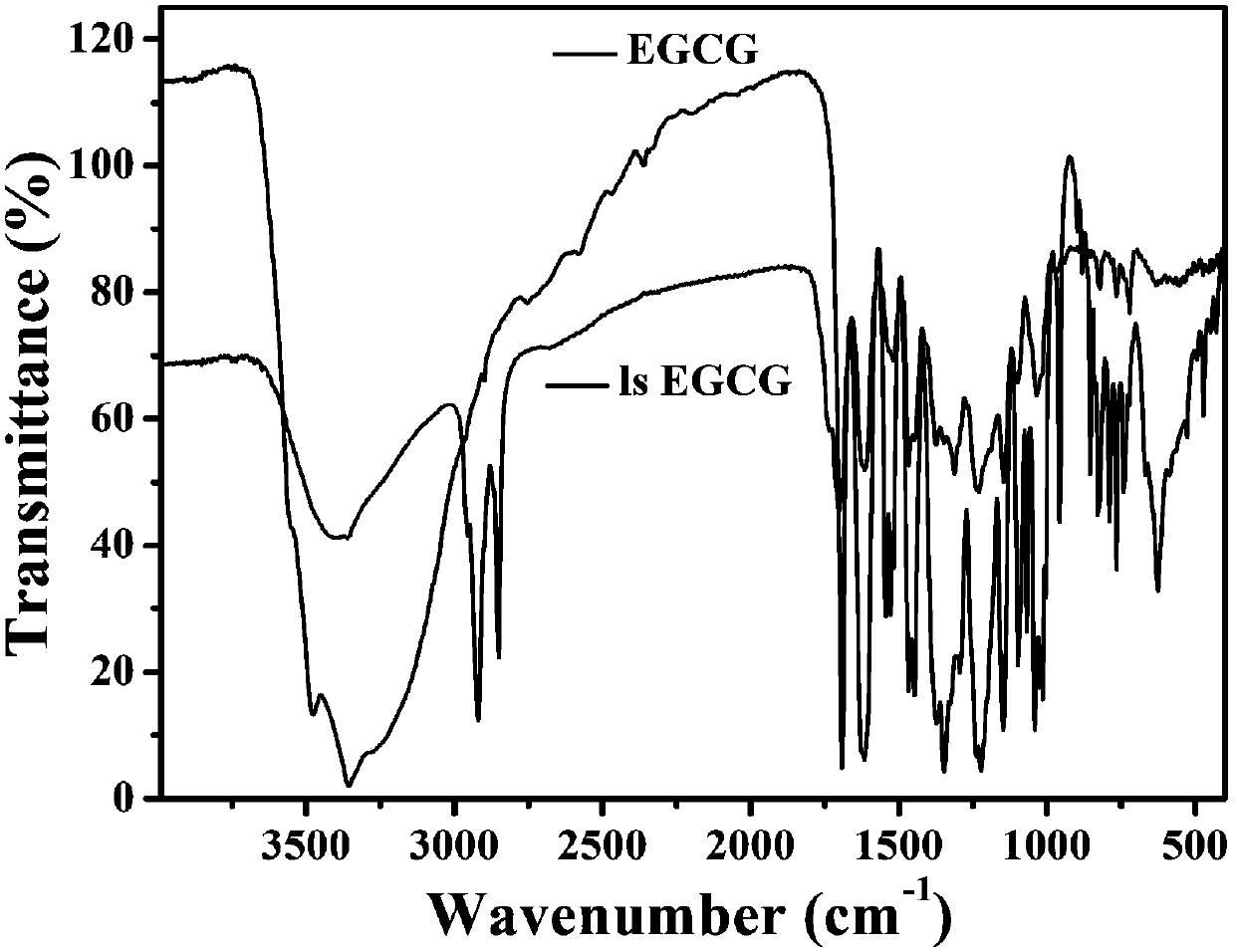

[0036] According to the present invention, the selected ultra-high molecular weight polyethylene is biomedical grade, and the relative molecular mass is 5 × 10 6 ~6×10 6 g / mol, the density is 0.93 ~ 0.98 g / cm 3 , the particle diameter is 120 ~ 160 μm. The selected polyphenolic antioxidants were epigallocatechin gallate (EGCG...

Embodiment 1

[0047] (1) EGCG doped UHMWPE: UHMWPE and EGCG (where EGCG accounts for 0.20% of the total mass of UHMWPE and EGCG) were added to isopropanol, and the stirring was continued for 3 h to ensure sufficient and uniform dispersion of EGCG in UHMWPE. The above mixture was dried in a vacuum oven at 60 ºC for 7 days to completely remove the isopropanol.

[0048] (2) Compression molding: The obtained EGCG / UHMWPE mixed powder was placed in a mold, and the EGCG / UHMWPE mixed powder was molded at a temperature of 200 ºC and a pressure of 10 MPa, then slowly cooled to room temperature, and a blank was obtained after demoulding.

Embodiment 2

[0050] (1) EGCG doped UHMWPE: UHMWPE and EGCG (where EGCG accounts for 0.20% of the total mass of UHMWPE and EGCG) were added to isopropanol, and the stirring was continued for 3 h to ensure sufficient and uniform dispersion of EGCG in UHMWPE. The above mixture was dried in a vacuum oven at 60 ºC for 7 days to completely remove the isopropanol.

[0051] (2) Compression molding: The obtained EGCG / UHMWPE mixed powder is placed in a mold, and the EGCG / UHMWPE mixed powder is molded at a temperature of 200 ºC and a pressure of 10 MPa, and then slowly cooled to room temperature, and a blank is obtained after demoulding.

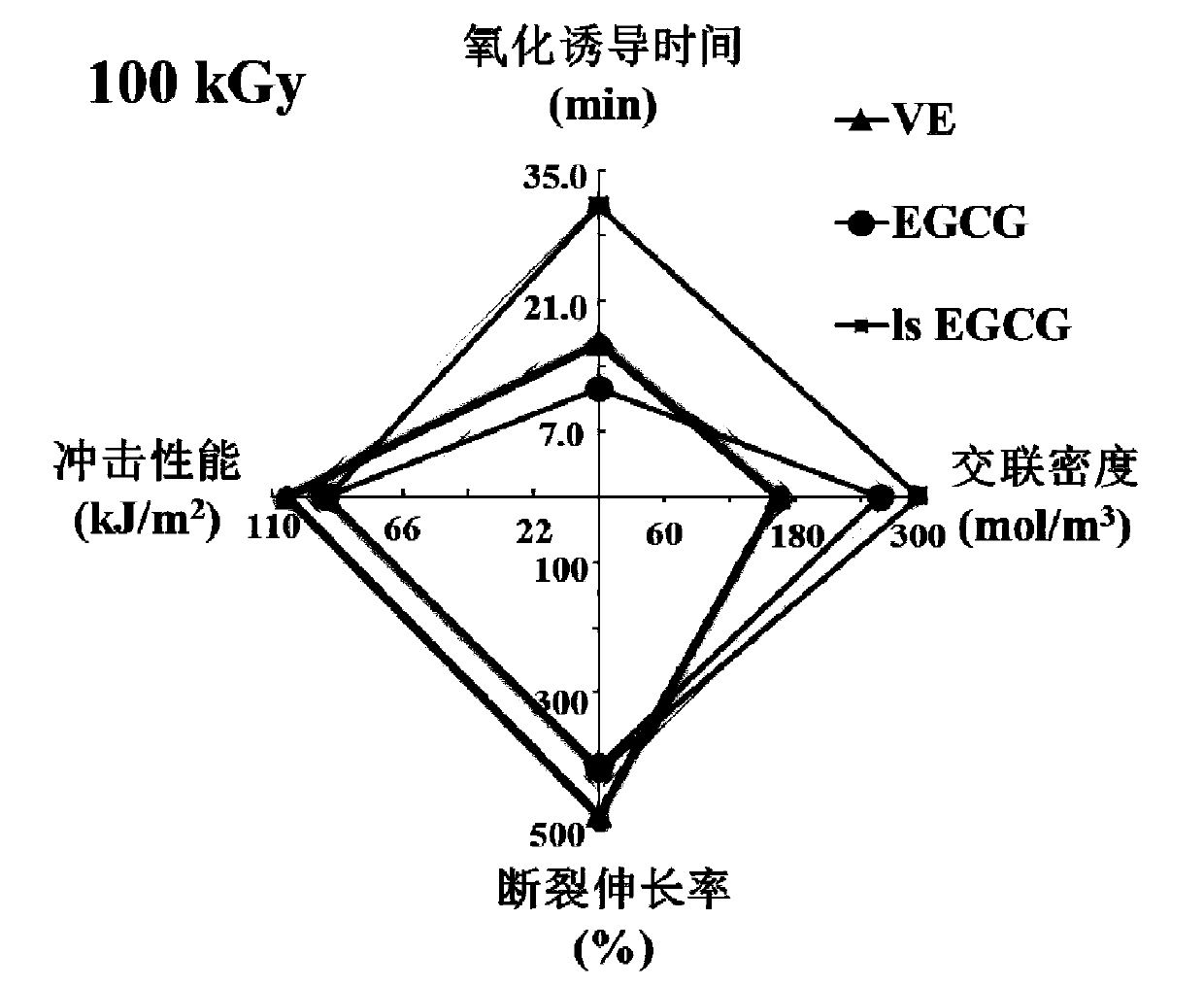

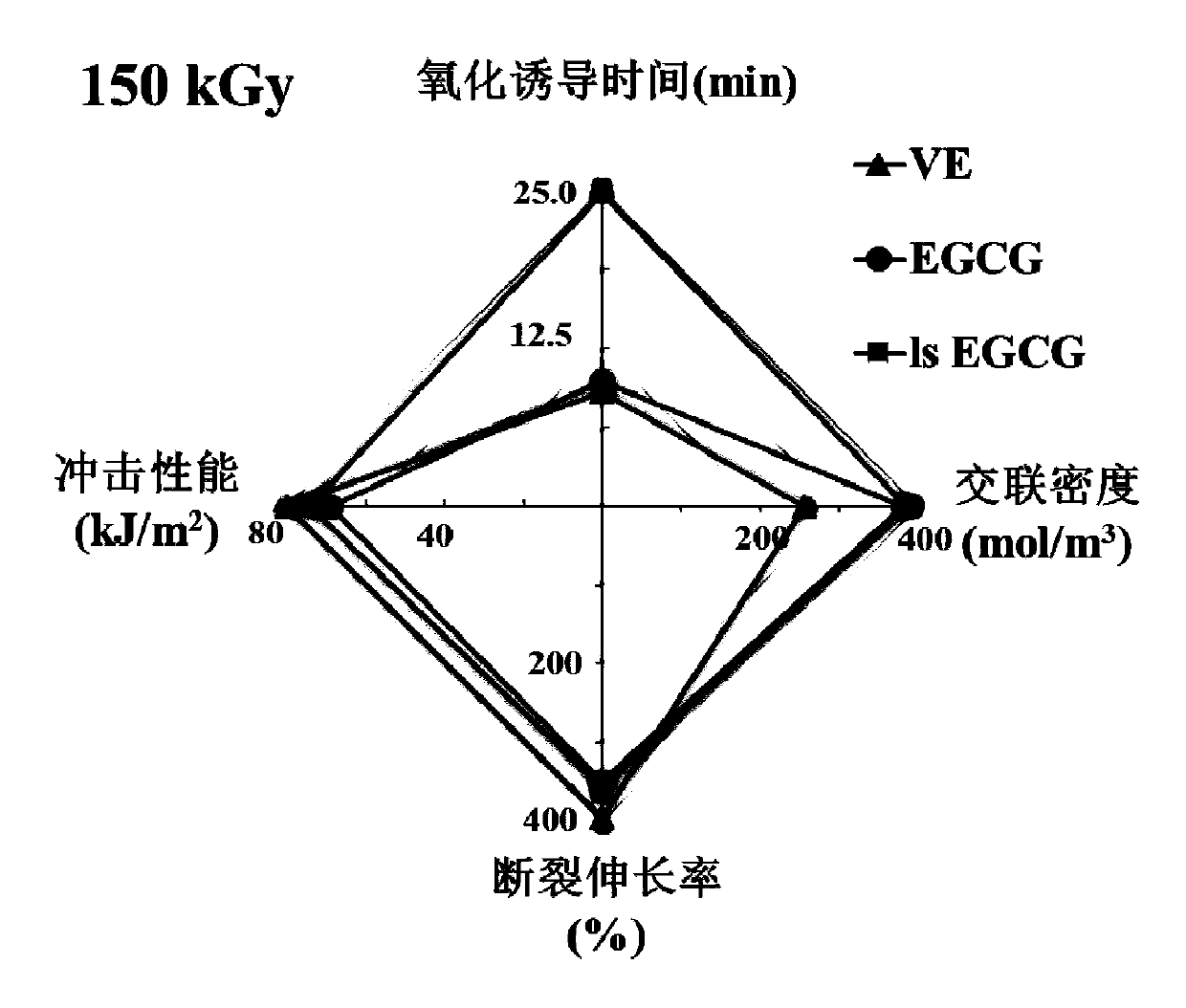

[0052] (3) Irradiation crosslinking: At room temperature, the vacuum-packed EGCG / UHMWPE molded blanks were irradiated with a 10 MeV electron beam, and the irradiation dose was 100 kGy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com