Ultraviolet (UV) adhesive tape and preparation method thereof

A tape and adhesive layer technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of easy residual glue, easy flying crystals, low degree of crosslinking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

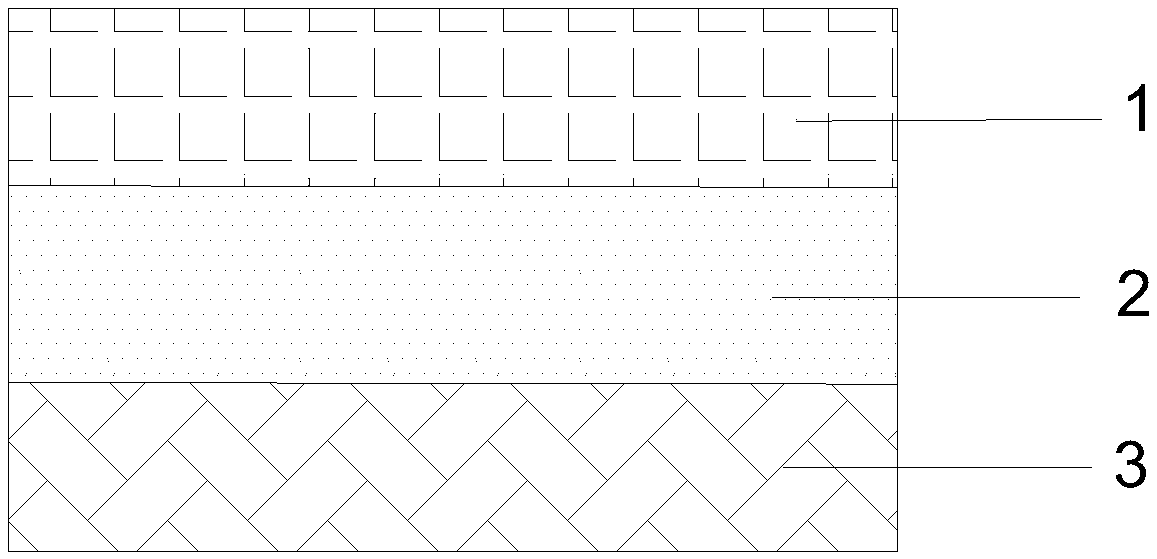

Image

Examples

Embodiment 1

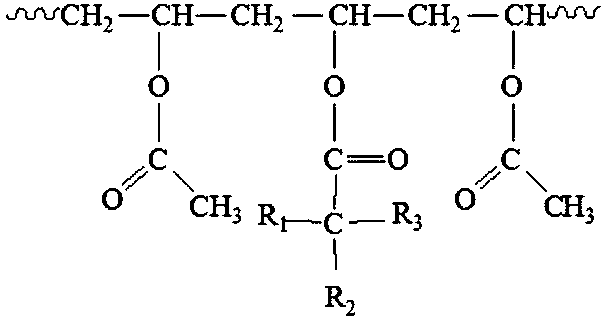

[0063] Acrylic resin with a glass transition temperature of -20 to -30°C: 80 parts;

[0064] Polyunsaturated resin containing multiple carbon-carbon double bonds in a single molecule: 20 parts;

[0065] Absorption wavelength of 265nm ~ 410nm photoinitiator: 3 parts;

[0066] Epoxy resin cross-linking agent: 2 parts;

[0067] UV glue layer The thickness of the glue layer is 20μm;

[0068] Implementation Effect:

[0069] Adhesion before lighting: 1200gf / 20mm

[0070] Adhesion after light exposure: ≦10gf / 20mm

Embodiment 2

[0072] Acrylic resin with a glass transition temperature of -20 to -30°C: 75 parts;

[0073] Polyunsaturated resin containing multiple carbon-carbon double bonds in a single molecule: 25 parts;

[0074] Absorption wavelength of 265nm ~ 410nm photoinitiator: 3 parts;

[0075] Epoxy resin cross-linking agent: 5 parts;

[0076] Adhesive layer thickness 10μm;

[0077] Implementation Effect:

[0078] Adhesion before lighting: 300gf / 20mm

[0079] Adhesion after light exposure: ≦10gf / 20mm

Embodiment 3

[0081] Acrylic resin with a glass transition temperature of -20 to -30°C: 75 parts;

[0082] Polyunsaturated resin containing multiple carbon-carbon double bonds in a single molecule: 25 parts;

[0083] Absorption wavelength of 265nm ~ 410nm photoinitiator: 3 parts;

[0084] Epoxy resin cross-linking agent: 3 parts;

[0085] Adhesive layer thickness 20μm;

[0086] Implementation Effect:

[0087] Adhesion before lighting: 500gf / 20mm

[0088] Adhesion after light exposure: ≦10gf / 20mm

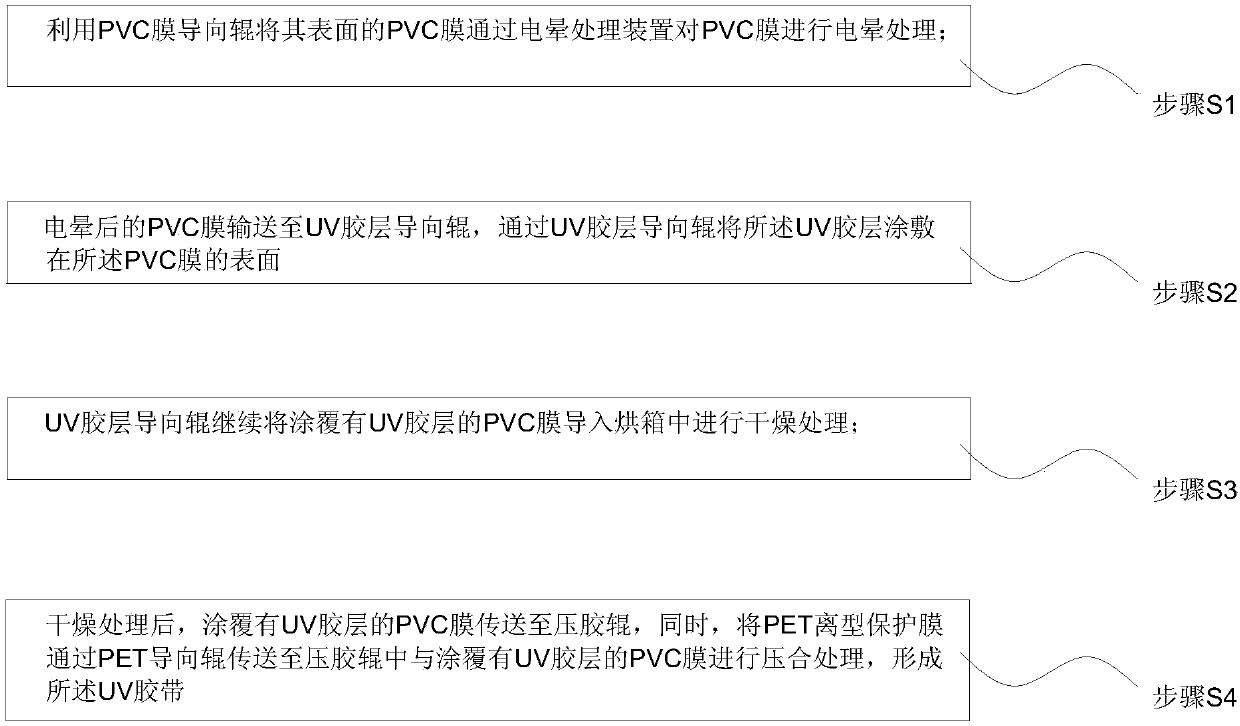

[0089] like figure 2 As shown, the technical solution of the present invention is aimed at the above-mentioned UV adhesive tape, and also provides a preparation scheme for UV adhesive tape, specifically including:

[0090] Step S1, using the PVC film guide roller to corona treat the PVC film on the surface of the PVC film through a corona treatment device; control the surface tension of the PVC film to be above 42 dynes;

[0091] Step S2, the PVC film after corona is transported to the UV ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com