Lithium-ion battery negative electrode material and preparation method thereof

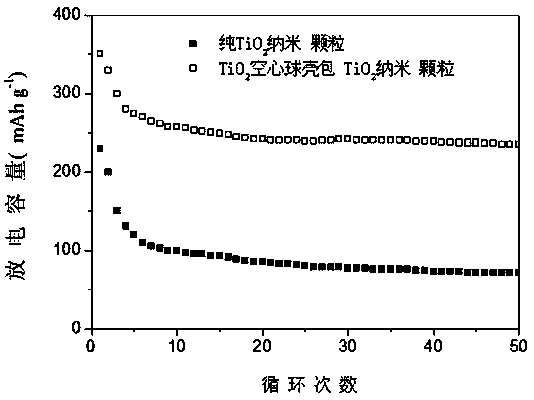

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low inter-particle bulk density, wide particle size distribution, poor charge-discharge performance, etc., and achieves a simple synthesis process, Low cost and the effect of improving capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare solution A: 9 mL 28% concentrated ammonia water + 16.25 mL ethanol + 24.75 mL water + 0.02 gCTAB, put in a beaker, stir magnetically for 15 min until the solution is evenly mixed, then add TiO 2 Nanoparticles (P25) 0.1 g, ultrasonically dispersed for 20 min.

[0025] Prepare solution B: 4.5 mL tetraethyl orthosilicate (TEOS) + 45.5 mL ethanol, mix well.

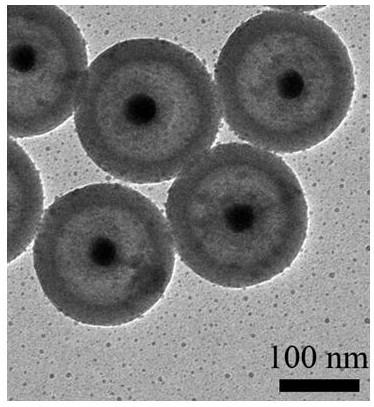

[0026] Quickly add solution B into the vigorously stirred solution A, seal the mouth of the beaker with plastic wrap, continue to stir and react at room temperature for 2 h, and the product SiO 2 The bag P25 was centrifuged and washed 3 times with absolute ethanol. The cleaned SiO 2 The package P25 was again placed in the mixed solution of absolute ethanol and deionized water, and 2 mL of isopropyl titanate (TIP) was added dropwise under the condition of vigorous stirring. Product TiO 2 Pack SiO 2 @P25. TiO 2 Pack SiO 2 @P25 Place in deionized water, heat to 95°C, keep warm for 2-10 hours, pour off the ...

Embodiment 2

[0032] Prepare solution A: 9 mL 28% concentrated ammonia water + 16.25 mL ethanol + 24.75 mL water + 0.02 gCTAB, put in a beaker, stir magnetically for 15 min until the solution is evenly mixed, then add TiO 2 Nanoparticles (P25) 0.2 g, ultrasonically dispersed for 20 min.

[0033] Prepare solution B: 4.5 mL tetraethyl orthosilicate (TEOS) + 45.5 mL ethanol, mix well.

[0034] The solution B was quickly added to the vigorously stirred solution A, the opening of the reaction beaker was sealed with plastic wrap, and the stirring reaction was continued at room temperature for 2 h. The product SiO 2 Pack P25 for centrifugation, wash with absolute ethanol for 3 times, and clean the SiO 2 The package P25 was placed in the mixed solution of absolute ethanol and deionized water again, under the condition of vigorous stirring, 1 mL of isopropyl titanate (TIP) was added dropwise, and the stirring reaction was continued for 30 min after the dropwise addition, and then the product was s...

Embodiment 3

[0038] Prepare solution A: 9 mL 28% concentrated ammonia water + 16.25 mL ethanol + 24.75 mL water + 0.02 gCTAB, put in a beaker, stir magnetically for 15 min until the solution is evenly mixed, then add TiO 2 Nanoparticles (P25) 0.5 g, ultrasonically dispersed for 20 min.

[0039] Prepare solution B: 4.5 mL tetraethyl orthosilicate (TEOS) + 45.5 mL ethanol, mix well.

[0040] Quickly add solution B to the vigorously stirred solution A, seal the mouth of the reaction beaker with plastic wrap, continue to stir and react at room temperature for 2 h, and the product SiO 2 The bag P25 was centrifuged and washed 3 times with absolute ethanol. The cleaned SiO 2 The package P25 was placed in the mixed solution of absolute ethanol and deionized water again, and 0.2 mL of isopropyl titanate (TIP) was added dropwise under the condition of vigorous stirring. Product TiO 2 Pack SiO 2 @P25. TiO 2 Pack SiO 2 @P25 Place in deionized water, heat to 95°C, keep warm for 2-10 hours, pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com