Preparation method of hydrogenation catalyst

A technology of hydrogenation catalyst and dosage, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unfavorable active metal dispersion, loss of carrier pore structure, high viscosity of impregnation solution, etc. Achieve the effect of reducing competitive adsorption, reducing viscosity and acidity, and facilitating uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

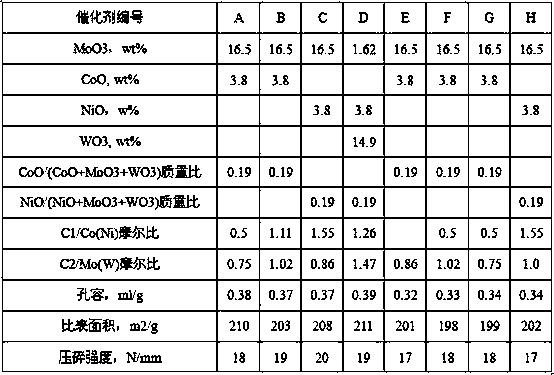

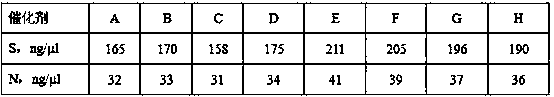

Embodiment 1

[0025] Put 100g of macroporous alumina powder (dry basis 85) in a rolling pan, and spray 80ml of 18.5g of cobalt nitrate and 1.1g of citric acid into the macroporous alumina powder in the rolling pan under the condition of rotation. After the solution is sprayed, continue to rotate in the rolling pan for 30 minutes, then place it for 3 hours, dry it at 110°C for 3 hours, put it into an atmosphere furnace and roast it for 2 hours, the protective gas is nitrogen, and the roasting temperature is 300°C.

[0026] Take out the modified macroporous alumina powder and 20g of small pore alumina powder (dry basis 75) and mix evenly, then add 2g of scallop powder, 25g of 10% phosphoric acid and 90ml of deionized water, knead, shape, and dry at 110°C for 4 hours , Calcined at 550°C for 3h to obtain an alumina carrier.

[0027] The alumina carrier that obtains is placed in the rolling pan, and under the condition of turning, spray 60ml into the rolling pan and contain 25.4g ammonium heptam...

Embodiment 2

[0029] Put 100g of macroporous alumina powder (dry basis 85) in the rolling pan, and spray 80ml of 18.5g of cobalt nitrate and 3.0g of oxalic acid into the macroporous alumina powder in the rolling pan under the condition of rotation. Aqueous solution, after the solution is sprayed, continue to rotate in the rolling pot for 30 minutes, then place it for 3 hours, dry it at 110°C for 3 hours, put it into an atmosphere furnace and roast it for 2 hours, the protective gas is nitrogen, and the roasting temperature is 350°C.

[0030] Take out the modified macroporous alumina powder and 20g of small pore alumina powder (dry basis 75) and mix evenly, then add 2g of scallop powder, 20g of 10% nitric acid and 90ml of deionized water, knead, shape, and dry at 110°C for 4 hours , Calcined at 550°C for 3h to obtain an alumina carrier.

[0031]The alumina carrier that obtains is placed in the rolling pan, and under the condition of turning, spray 60ml into the rolling pan and contain 25.4g ...

Embodiment 3

[0033] Put 100g of macroporous alumina powder (dry basis 85) in a rolling pan, and spray 80ml of 18.5g of nickel nitrate and 3.5g of tartaric acid into the macroporous alumina powder in the rolling pan under rotating conditions. Aqueous solution, after the solution is sprayed, continue to rotate in the rolling pot for 30 minutes, then place it for 3 hours, dry it at 110°C for 3 hours, put it into an atmosphere furnace and roast it for 2 hours, the protective gas is nitrogen, and the roasting temperature is 400°C.

[0034] Take out the modified macroporous alumina powder and 20g of small pore alumina powder (dry basis 75) and mix evenly, then add 2g of scallop powder, 20g of 10% nitric acid and 90ml of deionized water, knead, shape, and dry at 110°C for 4 hours , Calcined at 550°C for 3h to obtain an alumina carrier.

[0035] The alumina carrier that obtains is placed in the rolling pan, under the condition of turning, sprays 60ml into the rolling pan again and contains 25.4g a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com