Method for preparing fruit wine by fermentation of wastes generated in olive oil pressing

A waste and olive technology, which is applied in the field of fermenting fruit wine from olive oil pressing waste, can solve problems such as environmental pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The detection method of embodiment 1 polyphenol

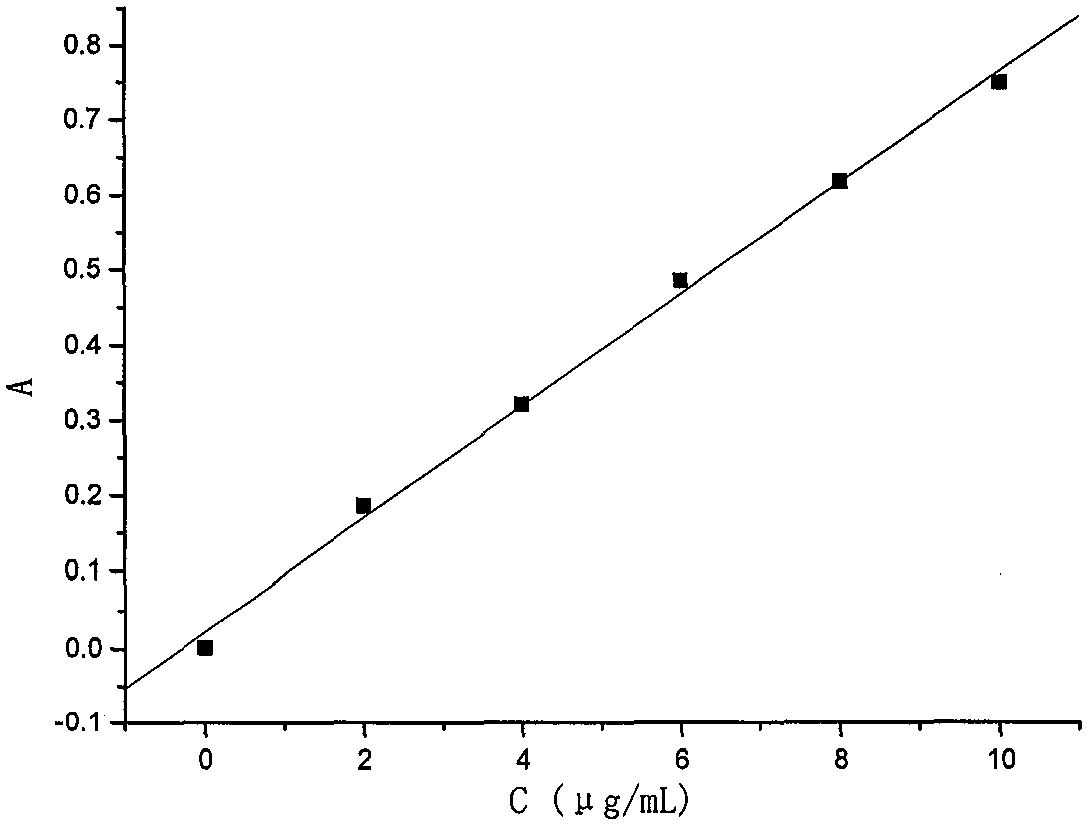

[0019] Accurately weigh an appropriate amount of gallic acid to prepare a certain concentration of gallic acid solution. Draw gallic acid standard solution 0mL, 0.20mL, 0.40mL, 0.60mL, 0.8mL and 1.0mL respectively into 10mL brown volumetric flask, so as to prepare 0, 2, 4, 6, 8 and 10μg / mL gallic acid solution in sequence, Add 1.0mL of FC reagent respectively, mix well, add 10% Na 2 CO 3 Solution 2.0mL, mix well, add water to volume, shake well. Let it stand for 60 minutes, and detect the absorbance value at 760nm. Draw the standard curve with the concentration of gallic acid (μg / mL) as the abscissa and the absorbance as the ordinate. The content of polyphenols in the samples was calculated based on gallic acid standard samples. Get the linear regression equation y=0.0713x+0.0445, and its correlation coefficient R 2 = 0.9985. It shows that polyphenols have a good linear relationship in the range of 2-10 μg / mL; whe...

Embodiment 2

[0019] Accurately weigh an appropriate amount of gallic acid to prepare a certain concentration of gallic acid solution. Draw gallic acid standard solution 0mL, 0.20mL, 0.40mL, 0.60mL, 0.8mL and 1.0mL respectively into 10mL brown volumetric flask, so as to prepare 0, 2, 4, 6, 8 and 10μg / mL gallic acid solution in sequence, Add 1.0mL of FC reagent respectively, mix well, add 10% Na 2 CO 3 Solution 2.0mL, mix well, add water to volume, shake well. Let it stand for 60 minutes, and detect the absorbance value at 760nm. Draw the standard curve with the concentration of gallic acid (μg / mL) as the abscissa and the absorbance as the ordinate. The content of polyphenols in the samples was calculated based on gallic acid standard samples. Get the linear regression equation y=0.0713x+0.0445, and its correlation coefficient R 2 = 0.9985. It shows that polyphenols have a good linear relationship in the range of 2-10 μg / mL; when detecting polyphenols in a sample, take a certain amount...

Embodiment 3

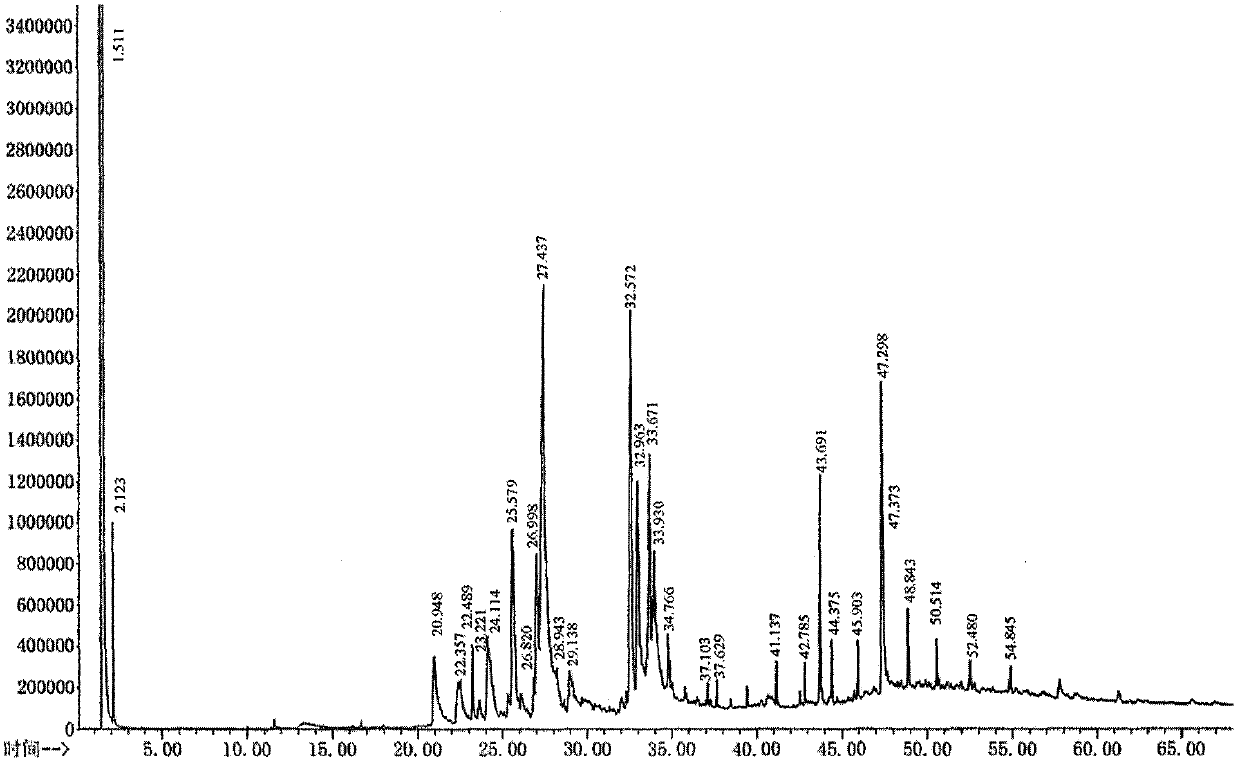

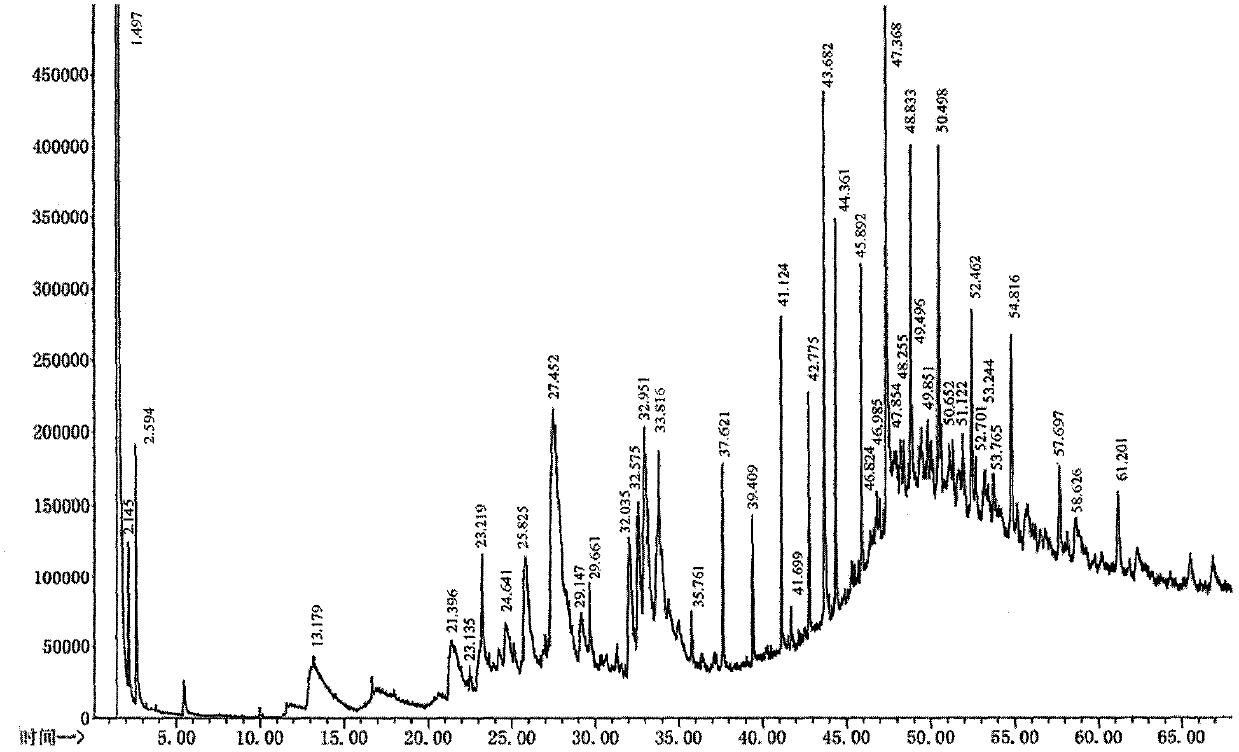

[0030] Embodiment 3GC-MS analysis comparison

[0031] In the present invention, a liquid-liquid extraction method is adopted, and dichloromethane is used to extract the olive pomace raw material liquid and the fermented sample for multiple times respectively.

[0032]Accurately measure 100 mL of olive pomace raw material liquid and fermented fruit wine sample into a separatory funnel, extract 3 times with 100 mL, 100 mL and 50 mL of dichloromethane in sequence, vibrate vigorously, let stand to separate layers, collect the extract from the lower layer, and combine . Add appropriate amount of anhydrous sodium sulfate for dehydration process, concentrate under reduced pressure to about 1.0mL, transfer the sample to EP tube for GC-MS analysis.

[0033] Gas chromatography conditions: chromatographic column is DB-5MS (30m×0.25mm×0.25μm); heating program: keep at 30°C for 5min, rise to 50°C at 2°C / min, keep for 5min, rise to 200°C at 10°C / min , keep for 6min, then rise to 230℃ at 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com