Broadband confocal method and device to measure refractive index of infrared lens element

A technology of measuring device and measuring method, which is applied in the field of measuring the refractive index of broadband confocal infrared lens elements, can solve the problems of complex measurement process, low precision, and inability to directly measure the refractive index of lens elements, and achieve high measurement accuracy and focused beam No dispersion, the effect of improving the measurement range and accuracy of the optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

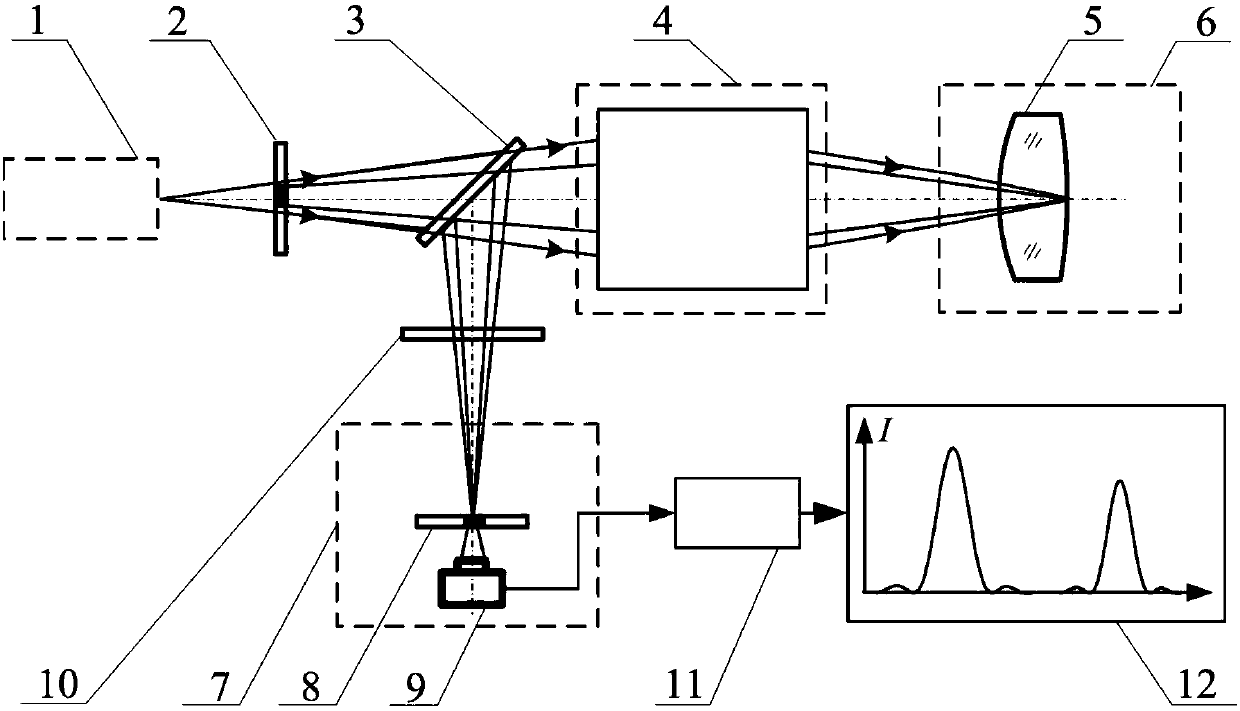

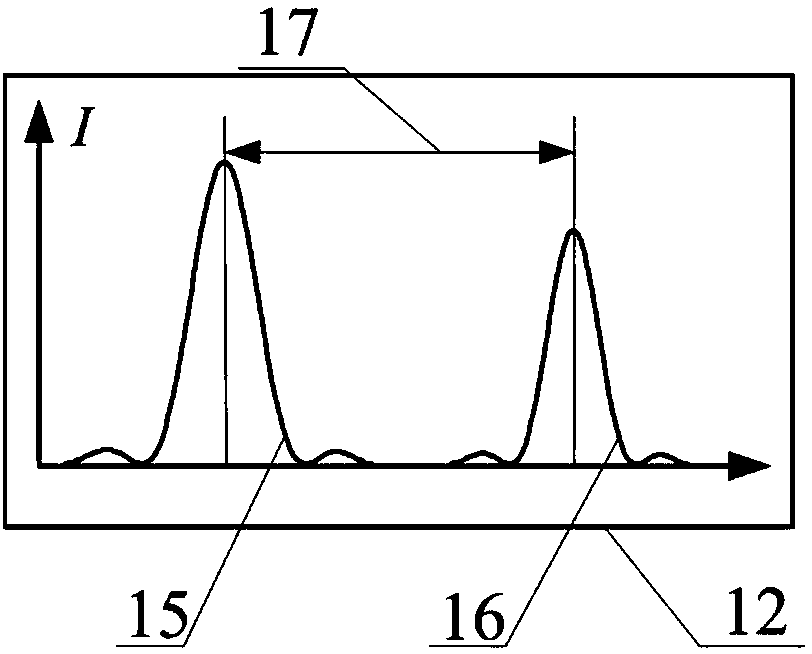

[0048] The embodiment of the present invention is based on Figure 4 The wide-band confocal infrared lens element refractive index measurement device shown is composed of a silicon carbon black body light source 13 and a grating monochromator 14 figure 1 Broadband point source system in 1. Composed of attitude adjustment system 20 and axial drive system 21 figure 1 In the adjustment and driving system 6, the wide-band spectroscopic system 3 adopts a wide-band spectroscopic sheet, and the detector 9 adopts a photodetector.

[0049] like Figure 4 As shown, the wide-band confocal infrared lens element refractive index measurement device includes: a silicon carbon black body light source 13, a grating monochromator 14 located in the exit direction of the silicon carbon black body light source 13, and a pupil filter located in the exit direction of the grating monochromator 14 2, wide-band spectroscopic system 3, wide-band collimation and convergence system 4, adjustment and dr...

Embodiment 2

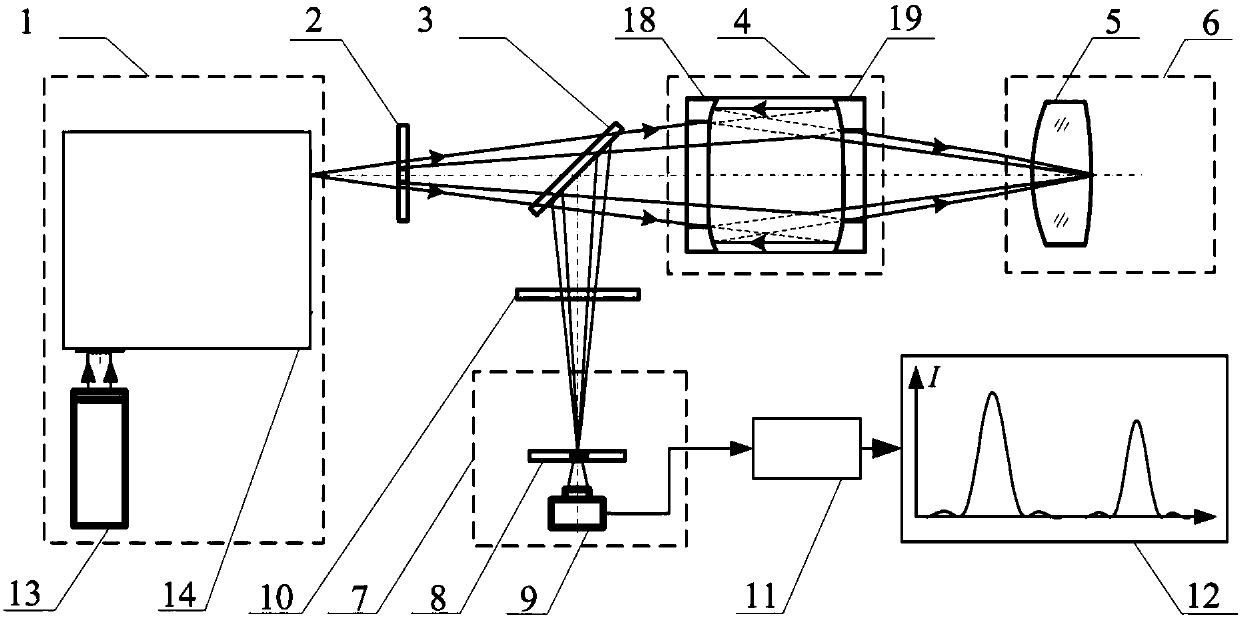

[0066] like Figure 5 In the shown broadband confocal infrared lens element refractive index measurement device, the device is composed of a silicon carbon black body light source 13 and a filter group monochromator 14 figure 1 The wide-band point light source system 1 is composed of a five-dimensional adjustment frame as the attitude adjustment system 20 and an air bearing guide rail as the axial drive system 21 figure 1 Adjustment and drive system in 6.

[0067] All the other measuring methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com