Lithium-ion battery diaphragm, lithium ion battery and preparation method thereof

A lithium-ion battery and diaphragm technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve the problems of inability to absorb batteries, poor high-temperature resistance of lithium-ion batteries, etc., and achieve easy winding, high temperature Excellent mechanical strength and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0047] The acrylate cross-linked polymer refers to a polymer obtained by cross-linking polymerization of reactive acrylate monomers. The crosslinking degree of the acrylate crosslinked polymer may be 2-30%, preferably 5-20%. In the present invention, the degree of crosslinking refers to the percentage of the weight of the crosslinked polymer to the total weight of the polymer. In addition, the glass transition temperature of the acrylate crosslinked polymer is preferably -20°C to 60°C, more preferably -12°C to 54°C. According to a preferred embodiment of the present invention, the acrylate crosslinked polymer is the second acrylate crosslinked polymer, the third acrylate crosslinked polymer, or the first acrylate crosslinked polymer A mixture with a second acrylate crosspolymer and / or a third acrylate crosspolymer; wherein the first acrylate crosspolymer contains 70-80% by weight of polymethyl methacrylate ester segment, 2-10% by weight of polyethyl acrylate segment, 10-20% ...

Embodiment 1

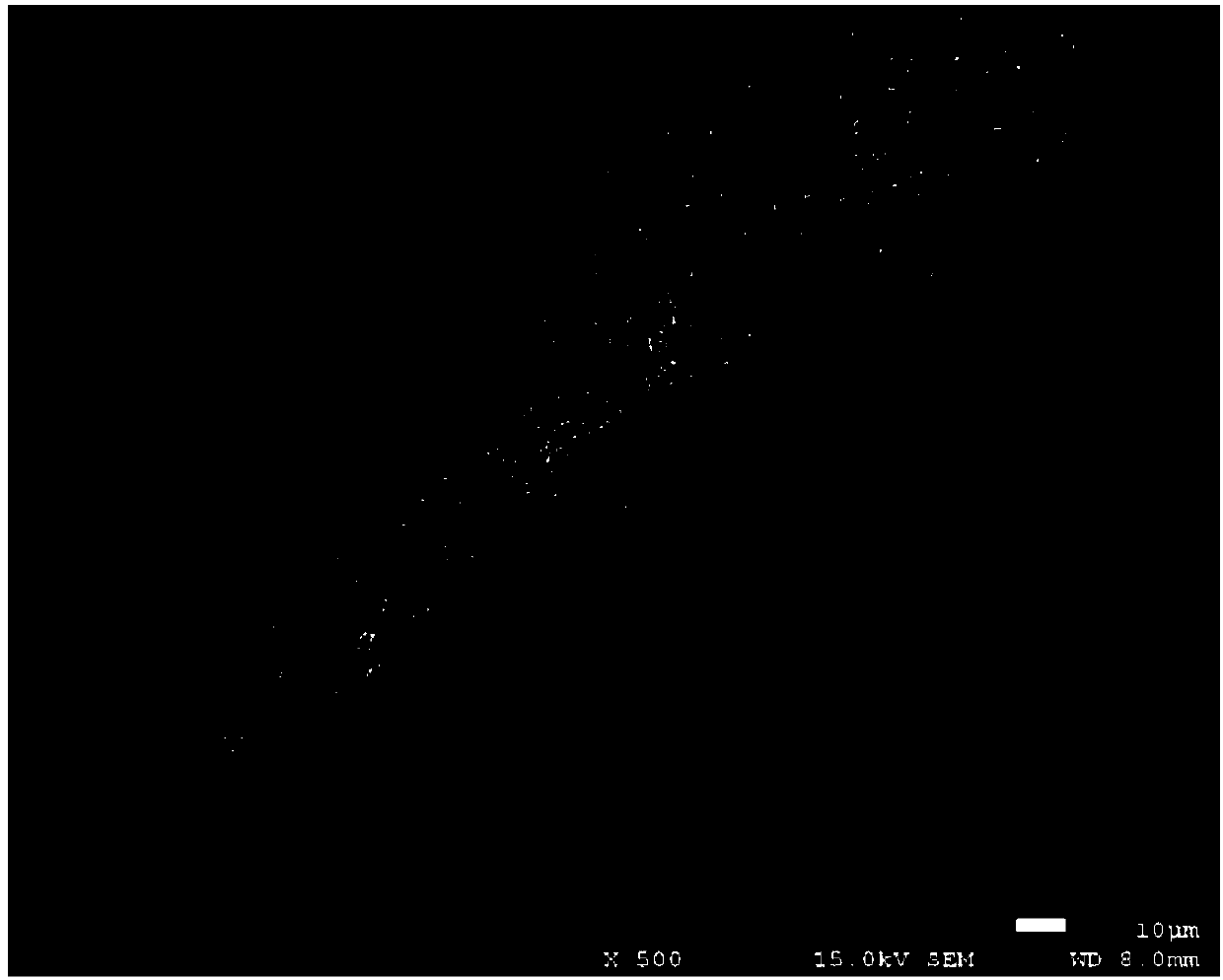

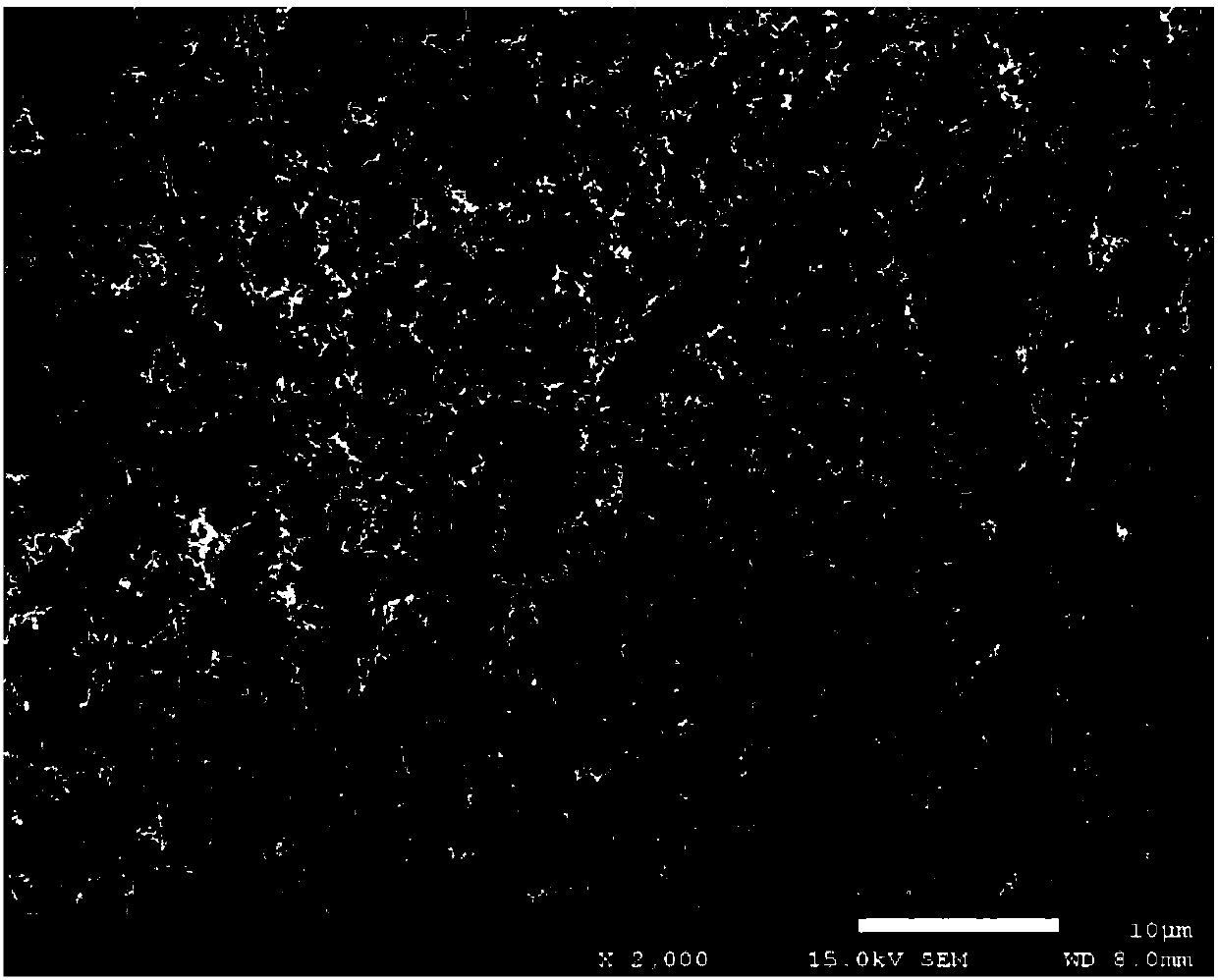

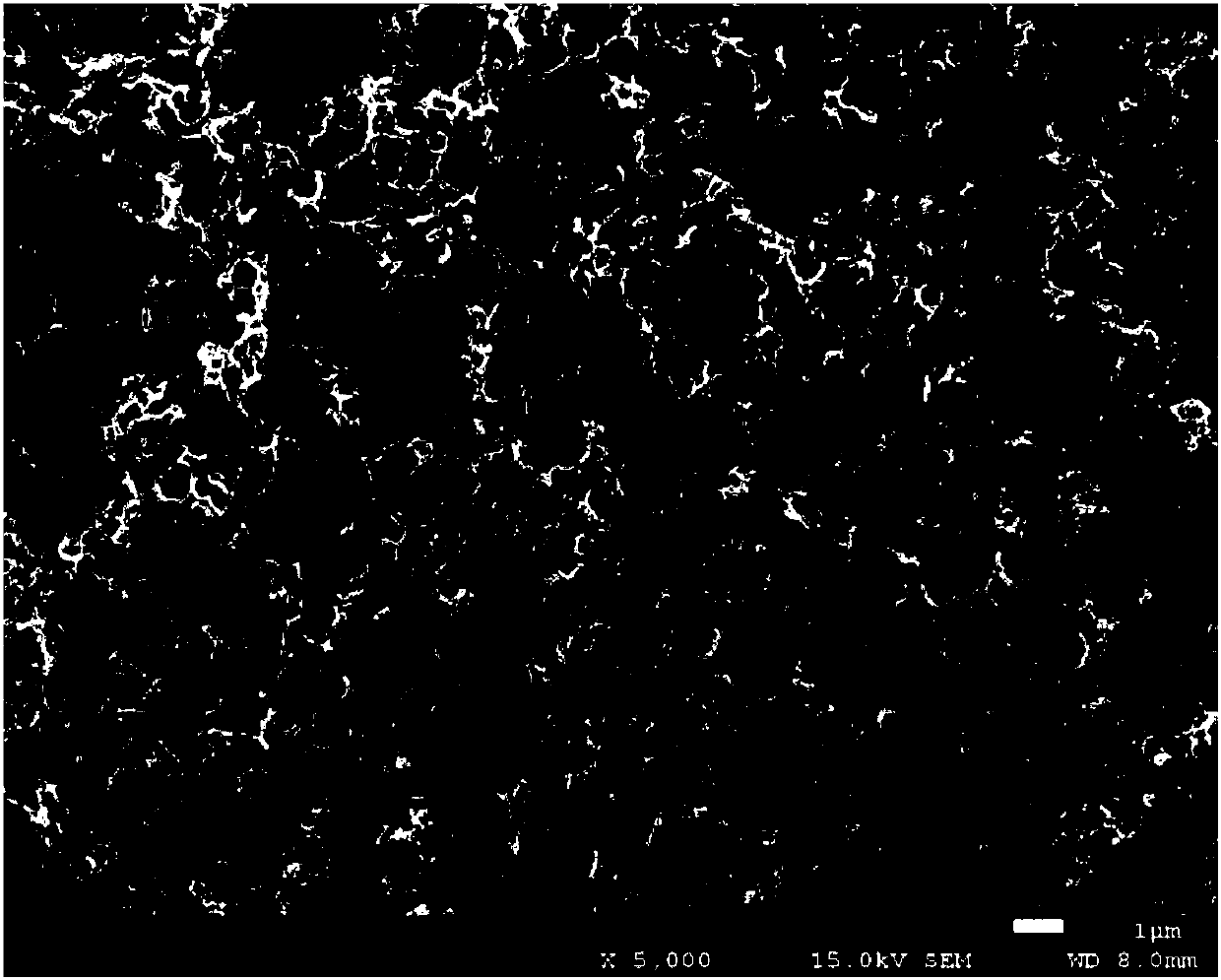

[0139] Example 1 (lithium-ion battery diaphragm of heat-resistant layer-porous base film (ceramic diaphragm)-heat-resistant layer three-layer structure)

[0140] This embodiment is used to illustrate the lithium-ion battery separator provided by the present invention and its preparation method.

[0141] (1) Preparation of ceramic diaphragm:

[0142] 2kg Al 2 o 3Particles (average particle diameter is 400nm), 0.01kg sodium polyacrylate (number average molecular weight is 9000, purchased from Guangzhou Yuanchang Trading Co., Ltd.), 0.024kg sodium carboxymethylcellulose (1% by weight aqueous solution viscosity is 2500-3000mPa s, purchased from Xinxiang Heluolida Power Supply Materials Co., Ltd., brand name BTT-3000) mixed with water evenly, so that Al 2 o 3 The solid content is the mixture of 30% by weight, the mixture was stirred at 6000rpm for 1.5 hours, then added 0.02kg of 3-glycidyl etheroxypropyl trimethoxysilane and continued to stir for 1.5 hours, then added 0.1kg pol...

Embodiment 2

[0146] Example 2 (porous base film (ceramic diaphragm)-lithium-ion battery diaphragm of heat-resistant layer two-layer structure)

[0147] This embodiment is used to illustrate the lithium-ion battery separator provided by the present invention and its preparation method.

[0148] (1) Preparation of ceramic diaphragm:

[0149] 2kg boehmite (average particle diameter is 300nm), 0.016kg sodium polyacrylate (number average molecular weight is 9000, purchased from Guangzhou Yuanchang Trading Co., Ltd.), 0.014kg carboxymethyl nanocellulose sodium (1% by weight aqueous solution Viscosity is 2500-3000mPaS, purchased from Xinxiang Heluolida Power Material Co., Ltd., the brand is BTT-3000) and water are mixed uniformly, so that the solid content of boehmite is a mixture of 50% by weight, and the mixture is heated at 8000rpm Stir for 1.5 hours, then add 0.01kg of 3-glycidyl etheroxypropyl trimethoxysilane and continue to stir for 1.5 hours, then add 0.12kg of polyacrylate binder (cross...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com