Field failure-considered robust fault-tolerant prediction control method and device

A predictive control and fault technology, applied in the field of permanent magnet synchronous motor control equipment, can solve the problems of control system divergence, model parameter mismatch, limited current predictive control application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

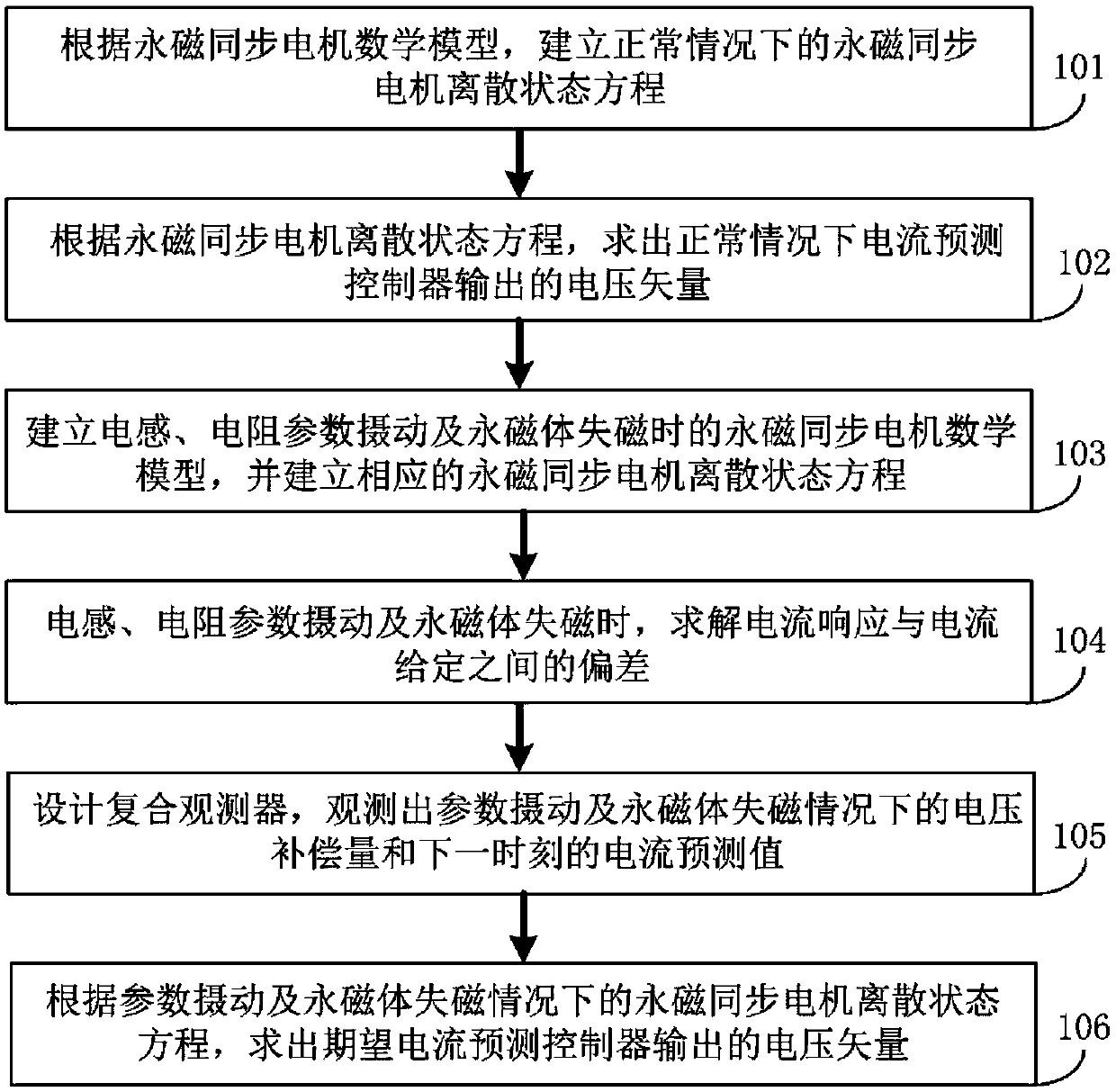

[0071] figure 1 It is a flowchart of an embodiment of the robust fault-tolerant predictive control method considering the loss of field fault provided by the present invention. The robust fault-tolerant predictive control method includes the following steps:

[0072] Step 101, according to the mathematical model of the permanent magnet synchronous motor, establish the discrete state equation of the permanent magnet synchronous motor under normal conditions,

[0073] i(k+1)=E o (k)·i(k)+F o ·u(k)+P o (k)

[0074] In the formula, i(k)=[i d (k)i q (k)] T , u(k)=[u d (k) u q (k)] T , u d (k), u q (k), i d (k), i q (k) are the voltage and current on the d and q axes respectively; ω(k) is the electrical angular velocity; ψ ro , R, L d , L q are permanent magnet flux linkage, stator resistance and d, q axis inductance respectively; T s is the sampling period.

[0075] Step 102, according to the discrete state equation of the permanent magnet synchronous motor, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com