Complex for replacing plasma protein powder, yeast hydrolyzate composition, preparation method and application

A technology of yeast hydrolyzate and compound, applied in application, animal feed, animal feed, etc., to achieve broad application prospects, improve immune performance, and increase growth speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

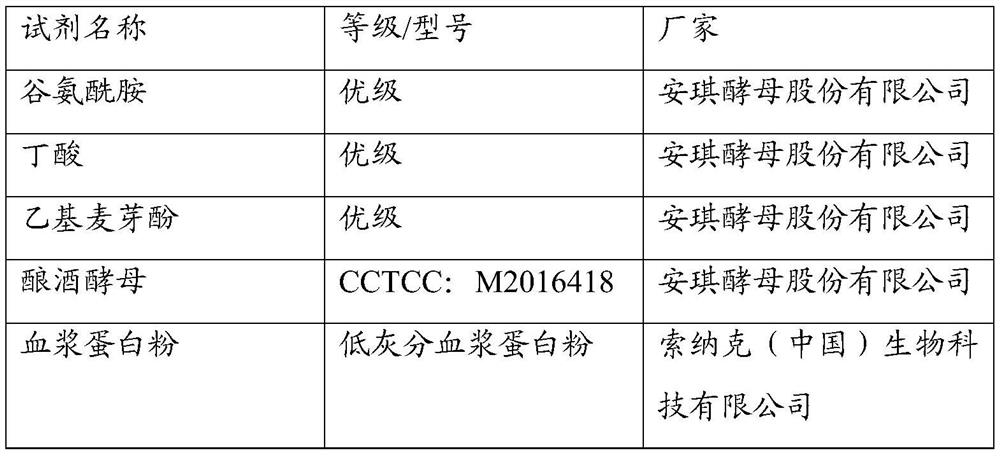

[0034]The preparation of embodiment 1 yeast hydrolyzate

[0035] Using Saccharomyces cerevisiae strain CCTCC NO: M2016418 of Angel yeast as the strain, inoculate the slant strain into a 20L stainless steel culture tank, and then insert 10M 3 Stainless steel fermenter, after 1060M 3 Large fermenter for primary culture, and then at 160M 3 The large fermenter is used for secondary culture, and the secondary culture is 7 hours, separated and washed to obtain high-nucleic acid yeast milk. Wherein the fermentation medium is molasses (MS): the concentration is 29%, the N source uses urea, the P source uses ammonium dihydrogen phosphate, the concentration of N element is 18%, and the P concentration is equivalent to P 2 o 5 14%.

[0036] After the bacteria are obtained by fermentation, adjust the concentration of yeast slime to 14wt%, then raise the temperature to 50°C, autolyze for 8 hours; then raise the temperature to 60°C, add 0.1-0.5% neutral protease, enzymolysis for 10 hour...

Embodiment 2

[0038] The preparation of embodiment 2 yeast hydrolyzate composition

[0039] 100 kg of glutamine, 20 kg of butyric acid, and 5 kg of ethyl maltol were mixed to obtain a mixture, and then 15 kg of the mixture was added to 85 kg of the yeast hydrolyzate prepared in Example 1 to obtain yeast hydrolyzate composition 1#.

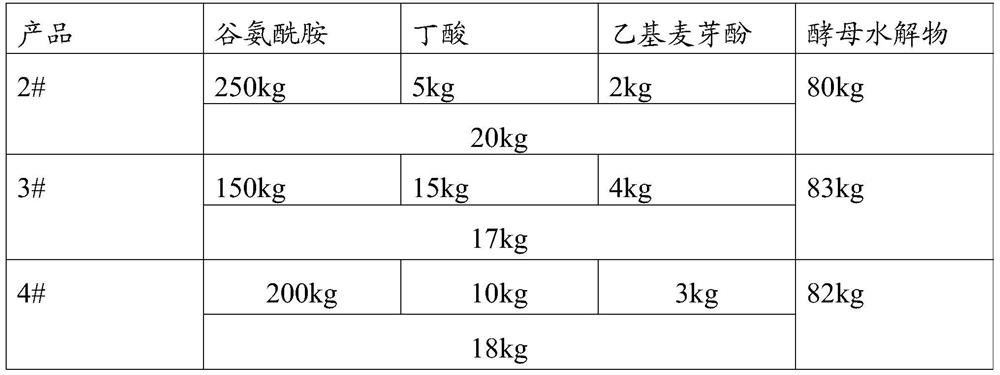

[0040] Yeast hydrolyzate compositions 2#-4# were prepared according to the same method as above, the difference lies in the content of each component, as shown in Table 2.

[0041] Table 2

[0042]

[0043] According to the same method as above, prepare comparative yeast hydrolyzate a#-c#, the difference lies in the content of each component, as shown in Table 3

[0044] table 3

[0045]

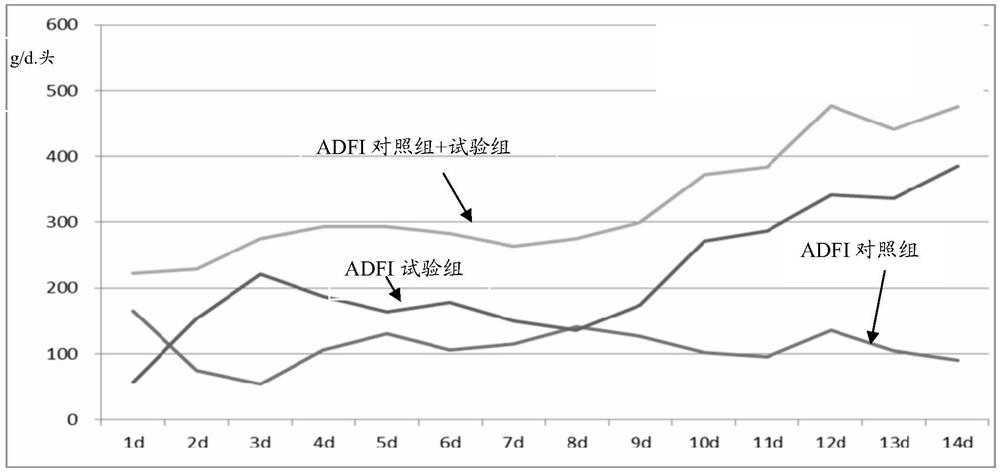

[0046] According to the method of functional comparison, the main efficacy of plasma protein powder used in feed will be analyzed, and the impact of yeast hydrolyzate composition replacing plasma protein powder on feed intake, immune performance and growth rate of pigl...

Embodiment 3

[0049] Prepare special feed for piglets according to the following steps:

[0050] Feed raw materials are as follows by weight percentage: 57.0% corn; 21.0% soybean meal; 10.0% whey powder; 1.0% salt; 6.0% vegetable oil; 1% premix can provide per kilogram of full price diet: Fe 150mg, Cu 195mg, Zn 150mg, Mn 30mg, I 0.3mg, Se 0.3mg, VA 12000IU, VD33200IU, VE 80IU, VK 32.5mg, VB1 2.5mg , VB2 6.5mg, VB6 5mg, VB12 0.05g, niacin 45mg, pantothenic acid 20mg, folic acid 1.5mg, biotin 0.15mg, trace compound enzymes, antibiotics, antifungal agents and antioxidants.

[0051] Control group: the diet was the basic diet+4% plasma protein powder,

[0052] Test group: the diet is the basic diet + 4% yeast hydrolyzate composition 1#

[0053] Twelve weaned piglets with the same genetic background, the same age and body weight as possible, and good body condition were selected. According to the principle of similar body weight, male and female were divided into 3 replicates, each replicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com