Catalytic oxidation deodorization process and catalytic oxidation deodorization device

A catalytic oxidation and process technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of ozone overflow, surrounding environment damage, etc., and achieve the effects of sufficient reaction contact area, low energy consumption, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A catalytic oxidation deodorization process, comprising the following steps:

[0044] 1) Ozone is produced by an ozone generator, and ozone is mixed with high-pressure water through a jet mixer; the pressure of the high-pressure water is 3kg / cm 2 ;

[0045] 2) Using hematite slag as a catalyst, the jet mixed gas-liquid obtained in step 1) is used to treat the odor at a pH of 3-4 and a temperature of 30°C;

[0046]3) Carry out gas-liquid separation to the odor after step 2) treatment.

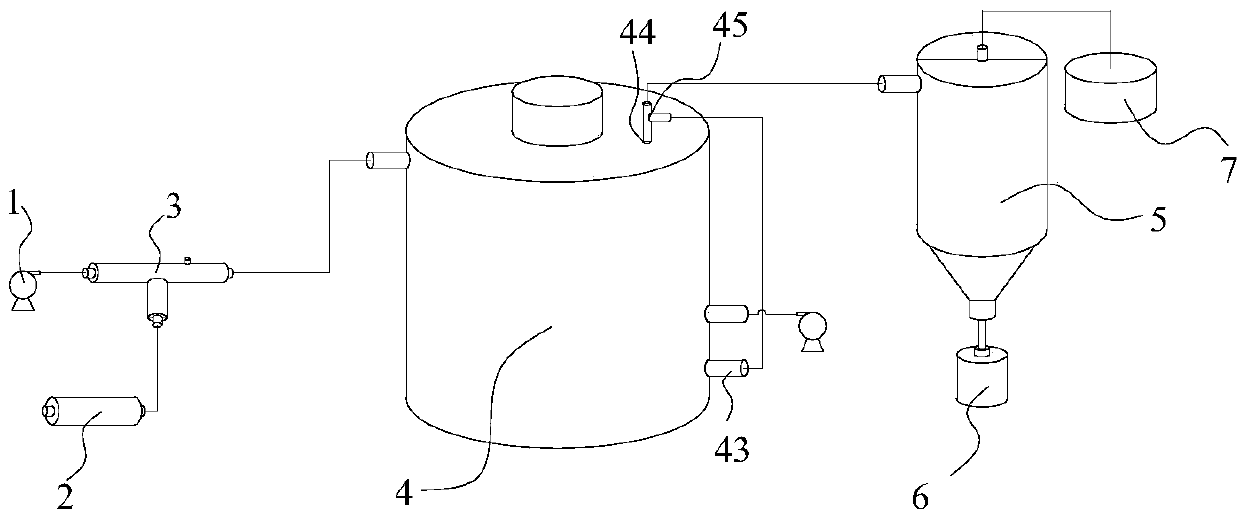

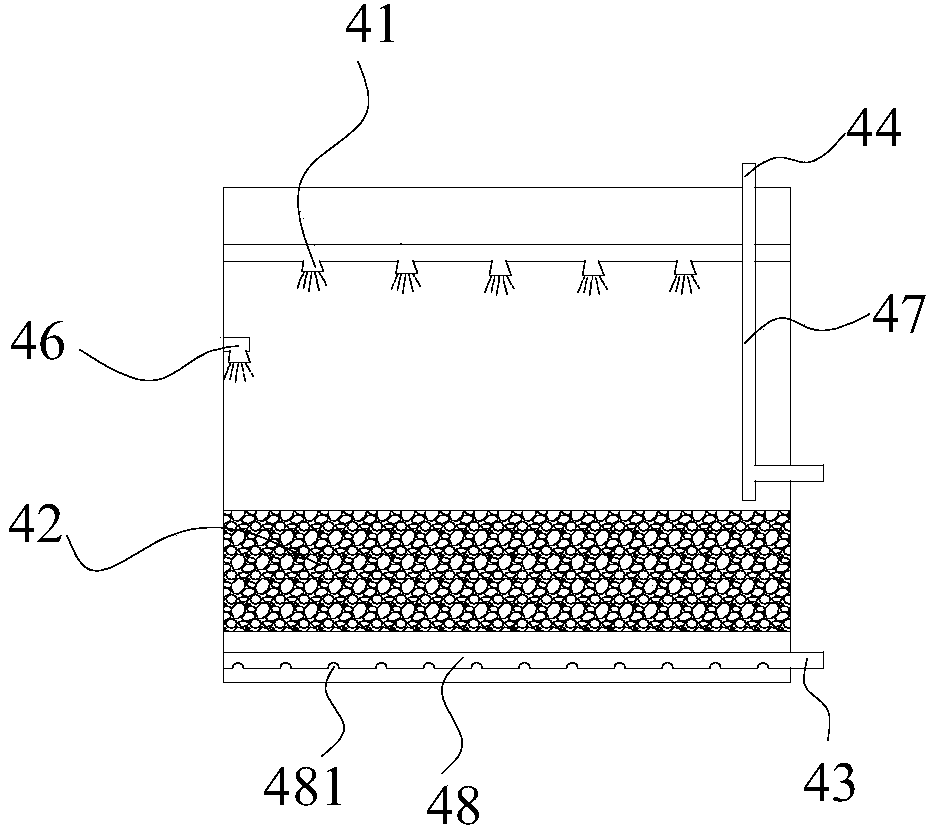

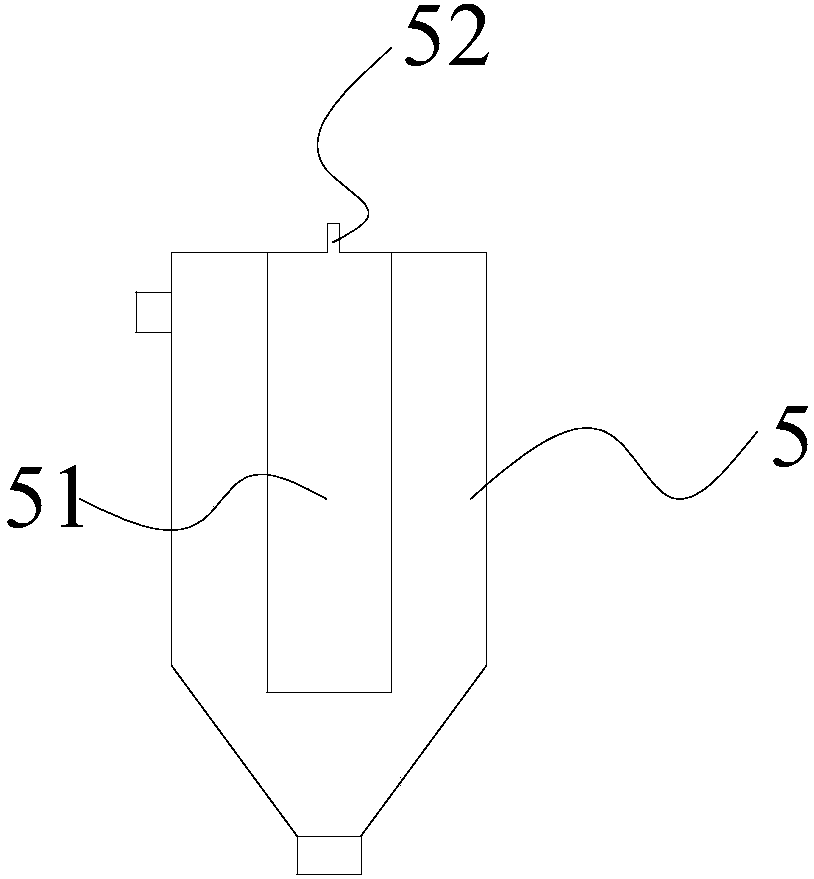

[0047] Implement the catalytic oxidation deodorization device of this method, comprise high-pressure injection head 1, ozone generator 2, jet mixer 3, oxidation reaction tower 4 and gas-liquid separator 5; Described oxidation reaction tower is provided with filler 42, and filler is red Iron ore slag, the particle diameter of filler is 20-30mm, the height of described oxidation reaction tower is 3m, and the height of filler is 1.8m; The top of described oxidation reaction tower is provid...

Embodiment 2

[0054] On the basis of embodiment 1, embodiment 2 also increases automatic control system, comprises control system, ozone concentration detector, pH detector and odor detector, and described ozone concentration detector is used for detecting the concentration signal of ozone in the reaction system And feed back to the control system, the control system adjusts the flow of the ozone generator according to the concentration signal instruction of the ozone; the pH detector is used to detect the pH value signal in the oxidation reaction tower and feeds back to the control system, The control system adjusts the opening or closing of the acid liquid nozzle according to the pH value signal instruction; the odor detector is used to detect H 2 S and / or NH 3 The concentration signal and feed back to the control system, the control system according to the H 2 S and / or NH 3 The concentration signal instructs the discharge port to discharge or not.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com