Forming method and device of blowing curing method 3D printing casting sand mold

A 3D printing and sand molding technology, which is applied in the direction of mold composition, casting molding equipment, and equipment for handling molds, etc., can solve the problems of high incidence of casting defects, high sand mold resin content, slow curing speed, etc., and achieve high molding efficiency , Good collapsibility and easy sand removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

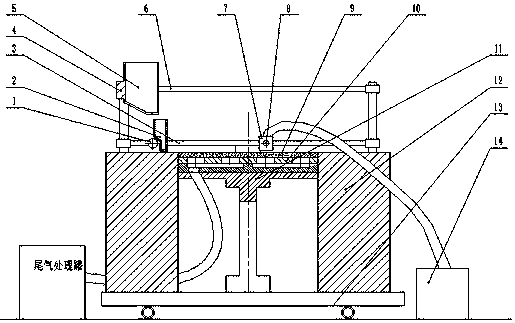

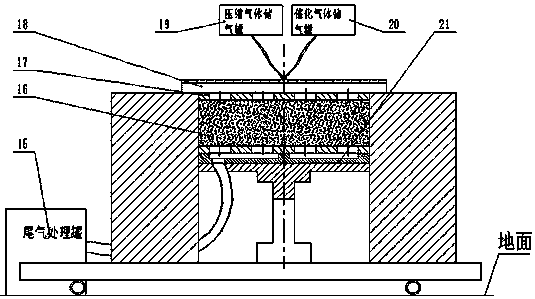

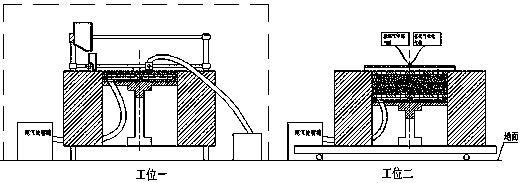

[0049] refer to image 3 As shown, the molding method and device for printing sand molds using the blowing solidification method 3D printing casting sand mold provided by the present invention are as follows:

[0050] Step 1: According to the 3D CAD model of the sand mold, slice and layer, and obtain detailed cross-sectional profile information of each layer;

[0051]Step 2: Prepare quartz sand with a particle size of 70 / 140 mesh in the first area of the station, and put the quartz sand into the sand storage tank 5 as the raw material for 3D printing molds;

[0052] Step 3: Before printing the sand mold, first clean the floating sand on the frame of the base 12 of the 3D printing forming system and the movable worktable 21, so that the working ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com