Double-liquid compound casting method for automobile mold casting

A compound casting and automobile mold technology, applied in the field of mold casting, can solve the problems of reducing the mechanical properties of the workpiece, not being able to mix, mix or cold shut, and achieve the effects of reducing pore defects, prolonging the service life, and preventing insufficient pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

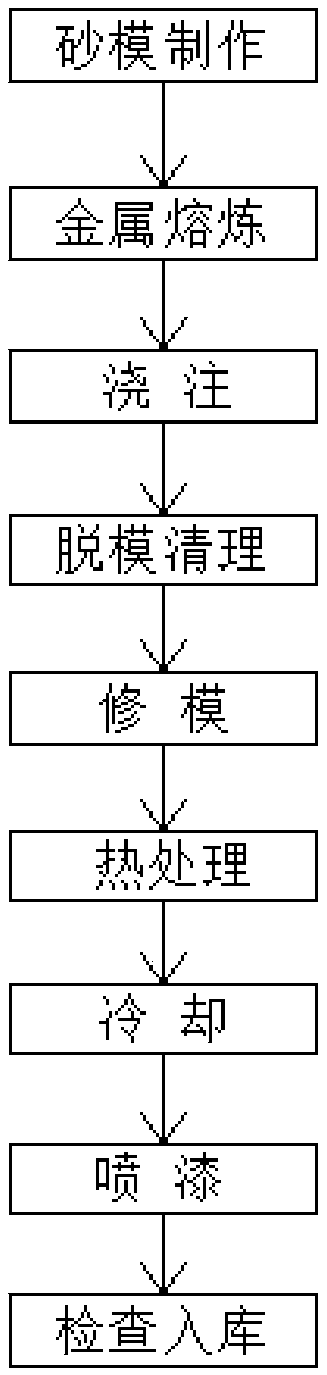

Image

Examples

Embodiment 1

[0034] A kind of double-liquid compound casting method that is used for automobile mold casting, concrete preparation steps are as follows:

[0035] Step 1: Sand mold making:

[0036] 1) Drawing: draw the matching sand mold drawing according to the pattern and size of the production accessories;

[0037] 2) Molding sand ratio: prepare new sand, old sand, coke grains and clay in proportion to the outer skin sand and core sand, and the ratio of outer skin sand is 20% of new sand, 75% of old sand and 5% of clay. The proportioning mass percentage is 25% of new sand, 60% of old sand, 5% of coke particles and 10% of clay;

[0038] 3) Molding: Use a molding machine to make the outer skin sand and core sand into molds and sand cores respectively;

[0039] Step 2: Metal smelting: Put the first metal raw material and the second metal raw material into a melting furnace and melt them into a molten state. The first metal raw material is high-chromium cast iron, and its melting temperatu...

Embodiment 2

[0048] A kind of double-liquid compound casting method that is used for automobile mold casting, concrete preparation steps are as follows:

[0049] Step 1: Sand mold making:

[0050] 1) Drawing: draw the matching sand mold drawing according to the pattern and size of the production accessories;

[0051] 2) Molding sand ratio: prepare new sand, old sand, coke grains and clay in proportion to the outer skin sand and core sand, and the ratio of outer skin sand is 20% of new sand, 75% of old sand and 5% of clay. The proportioning mass percentage is 25% of new sand, 60% of old sand, 5% of coke particles and 10% of clay;

[0052] 3) Molding: Use a molding machine to make the outer skin sand and core sand into molds and sand cores respectively;

[0053] Step 2: Metal smelting: put the first metal raw material and the second metal raw material into a melting furnace and melt them into a molten state. The first metal raw material is high-chromium cast iron, and its melting temperatu...

Embodiment 3

[0062] A kind of double-liquid compound casting method that is used for automobile mold casting, concrete preparation steps are as follows:

[0063] Step 1: Sand mold making:

[0064] 1) Drawing: draw the matching sand mold drawing according to the pattern and size of the production accessories;

[0065] 2) Molding sand ratio: prepare new sand, old sand, coke grains and clay in proportion to the outer skin sand and core sand, and the ratio of outer skin sand is 20% of new sand, 75% of old sand and 5% of clay. The proportioning mass percentage is 25% of new sand, 60% of old sand, 5% of coke particles and 10% of clay;

[0066] 3) Molding: Use a molding machine to make the outer skin sand and core sand into molds and sand cores respectively;

[0067] Step 2: Metal smelting: Put the first metal raw material and the second metal raw material into a melting furnace and melt them into a molten state. The first metal raw material is high-chromium cast iron, and its melting temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com