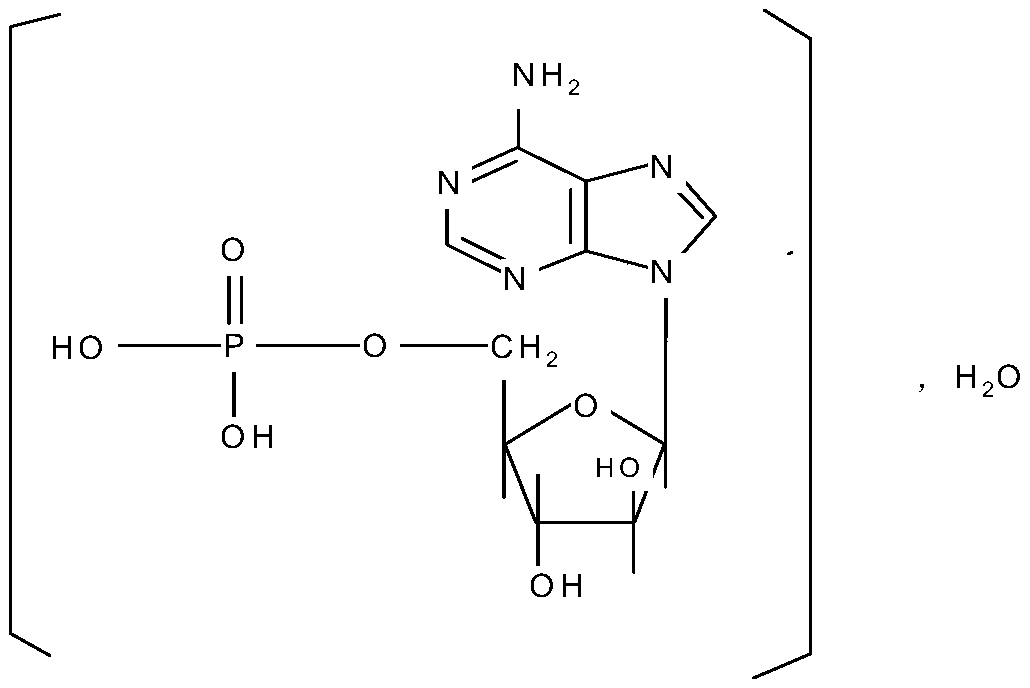

A kind of preparation method of adenosine monophosphate arabinoside

A technology for adenosine monophosphate and adenosine monophosphate wet crude product is applied in the field of preparation of adenosine monophosphate, which can solve the problems of complex process operation, affecting product yield and final product quality, etc. Simple process, low cost, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

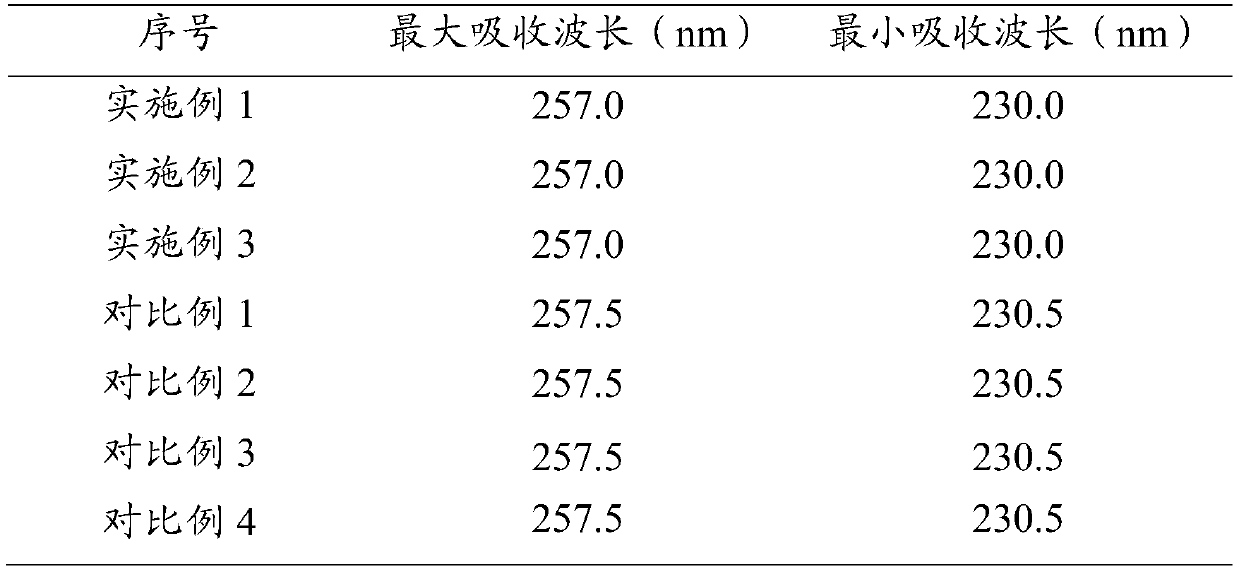

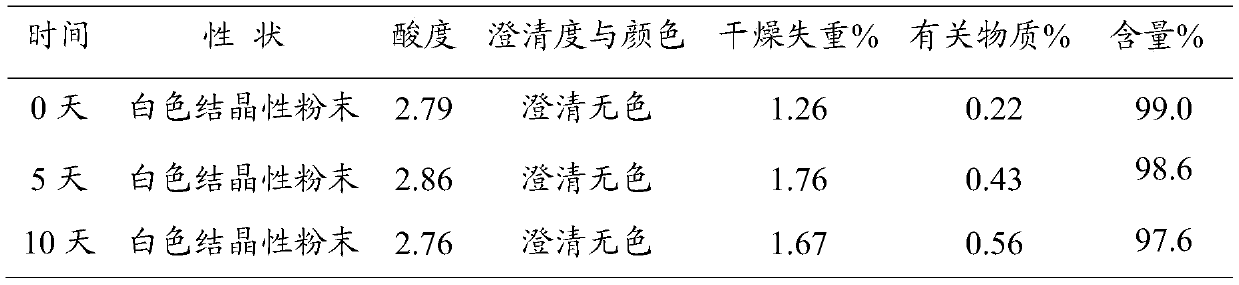

Examples

Embodiment 1

[0031] Synthesis of vidarabine monophosphate crude product:

[0032] 1. Prepare an aqueous sodium hydroxide solution with a mass fraction of 40%. Add 37.5 kg of purified water to a 50 L reaction kettle, add 15.0 kg of sodium hydroxide in portions under stirring, stir and dissolve for later use.

[0033] 2. Add 10.0 kg of β-D-adenosine vidarabine and 100.0 kg of triethyl phosphate into a 200L reaction tank, and cool down to -10°C.

[0034] 3. Add 10.2 kg of phosphorus oxychloride dropwise under stirring, control the temperature not higher than 0°C, and complete the dropwise addition within 3 to 5 hours; after the dropwise addition, stir and react at -5°C for 90 minutes, TLC detects that the reaction reaches the end point, stop reaction.

[0035] 4. Slowly pump the reaction solution into a 500L reaction tank (with 150kg of purified water pre-frozen to 0°C), and control the temperature not higher than 15°C.

[0036] 5. Cool down to 0°C, add dropwise NaOH aqueous solution with a...

Embodiment 2

[0049]Synthesis of vidarabine monophosphate crude product:

[0050] 1. Prepare an aqueous sodium hydroxide solution with a mass fraction of 40%. Add 37.5 kg of purified water to a 50 L reaction kettle, add 15.0 kg of sodium hydroxide in portions under stirring, stir and dissolve for later use.

[0051] 2. Add 10.0 kg of β-D-arabinoadenosine and 100.0 kg of triethyl phosphate into a 200L reaction tank, and cool down to -13°C.

[0052] 3. Add 10.2 kg of phosphorus oxychloride dropwise under stirring, control the temperature not higher than 0°C, and complete the dropwise addition within 3 to 5 hours; after the dropwise addition is completed, stir and react at -2.5°C for 120 minutes, and stop when the reaction reaches the end point by TLC. reaction.

[0053] 4. Slowly pump the reaction liquid into a 500L reaction tank (with 150kg of purified water pre-frozen to 1.5°C), and control the temperature not higher than 15°C.

[0054] 5. Cool down to 0°C, add dropwise NaOH aqueous solut...

Embodiment 3

[0067] Synthesis of vidarabine monophosphate crude product:

[0068] 1. Prepare an aqueous sodium hydroxide solution with a mass fraction of 40%. Add 37.5 kg of purified water to a 50 L reaction kettle, add 15.0 kg of sodium hydroxide in portions under stirring, stir and dissolve for later use.

[0069] 2. Add 10.0 kg of β-D-adenosine vidarabine and 100.0 kg of triethyl phosphate into a 200L reaction tank, and cool down to -15°C.

[0070] 3. Add 10.2 kg of phosphorus oxychloride dropwise under stirring, control the temperature not higher than 0°C, and complete the dropwise addition within 3 to 5 hours; after the dropwise addition, stir and react at -0°C for 150 minutes, and stop the reaction when it reaches the end point by TLC detection reaction. Add 10.2 kg of phosphorus oxychloride dropwise under stirring, and control the temperature not higher than 0°C.

[0071] 4. Slowly pump the reaction solution into a 500L reaction tank (with 150kg of purified water pre-frozen to 2°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com