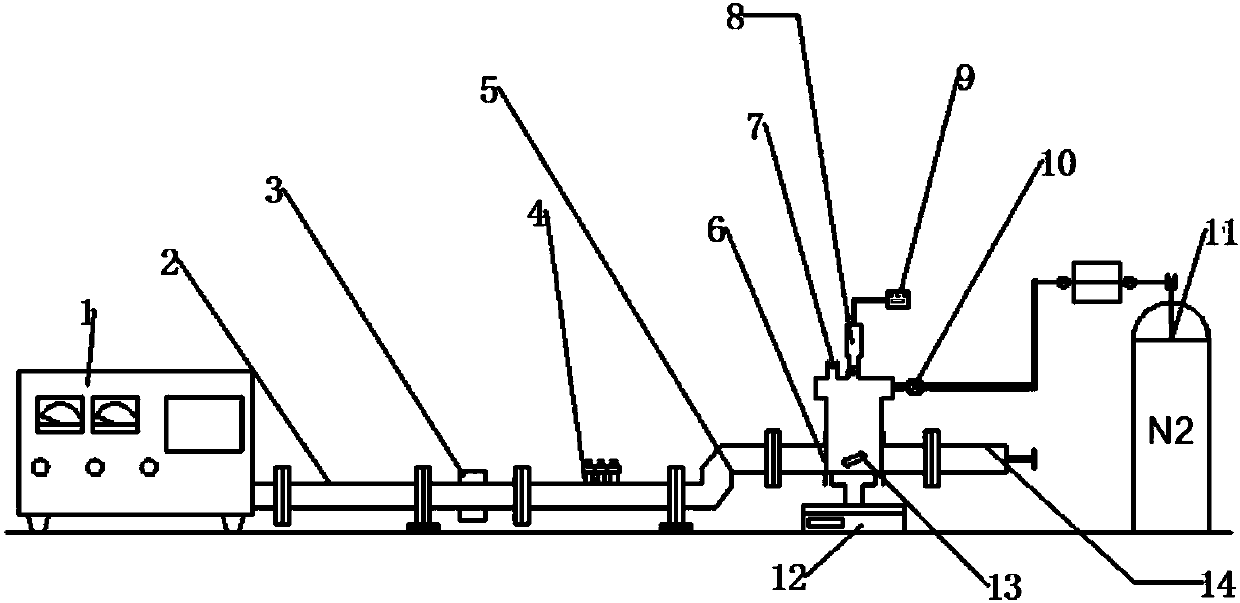

Microwave calorimeter for measuring material microwave heat effect and its calorimetric method

A technology of thermal effect and calorimeter, which is applied in the direction of material analysis, measuring device, and material analysis using microwave means, which can solve the problems of restricting the microwave absorption ability of materials, affecting the accuracy of results, and difficult control of pressure and power, so as to avoid Hot spot effect, avoid weighing process, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

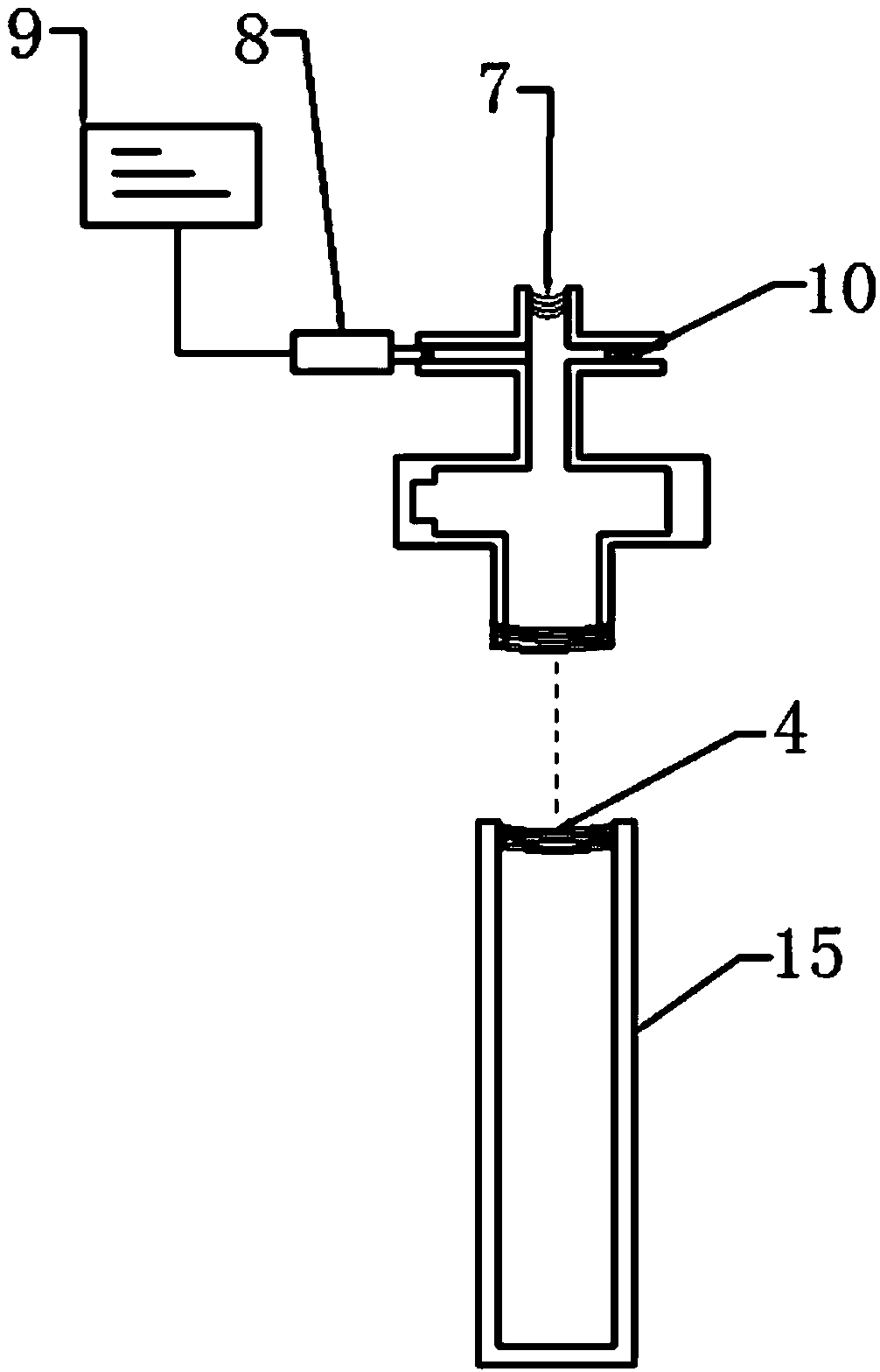

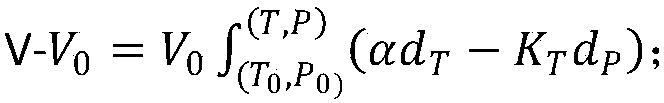

Method used

Image

Examples

Embodiment 2

[0047] The above-mentioned microwave calorimeter is used for measurement, carbon felt is used as the target material, and paraffin oil is used as the intermediate medium. Take 0.1g of carbon felt and 15g of paraffin oil into the reaction chamber through the liquid injection port 7, seal the reaction vessel, select 0s, 10s, 20s, 30s, 40s, 50s, and 60s as time parameters, and pass the pressure sensor 8 It is converted into a digital signal and displayed on the display panel 9 to obtain the temperature values at these 7 moments. The room temperature was 22°C during the measurement, and the temperature values at seven moments were 22°C, 46.4°C, 80.9°C, 101.2°C, 116.1°C, 140.5°C, and 156.2°C. From the above experimental results, it can be seen that the carbon felt can be irradiated with microwaves for one minute. The temperature rise of the intermediate medium reaches nearly 150°C, and this device accurately and clearly characterizes the microwave thermal effect of carbon felt....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com